High-temperature-resistant filter material, preparation method thereof and high-temperature-resistant dust-removing filter pipe

A filter material and high-temperature-resistant technology, which can be used in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of thermal shock resistance and dust removal efficiency that need to be further improved, so as to achieve rich pores, improve dust removal efficiency, Effect of good mechanical strength and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

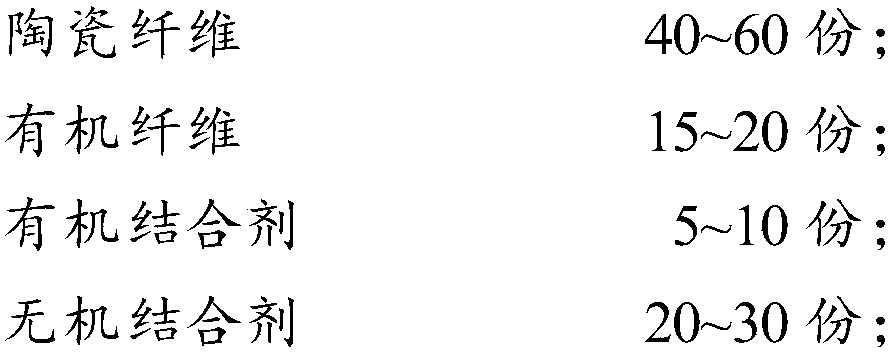

[0036] The present invention also provides a method for preparing the high temperature resistant filter material described in the above technical solution, comprising the following steps:

[0037] a) mixing ceramic fiber, organic fiber, organic binder, inorganic binder and water to obtain fiber slurry;

[0038] b) Calcining the fiber slurry to obtain a high temperature resistant filter material.

[0039]In the preparation method provided by the present invention, first ceramic fibers, organic fibers, organic binders, inorganic binders and water are mixed to obtain fiber slurry, and the specific process preferably includes a1) ceramic fibers, organic fibers, organic binders mixing with water to obtain an intermediate slurry; a2) mixing the intermediate slurry with an inorganic binder to obtain a fiber slurry. In the present invention, the total content of ceramic fibers, organic fibers and organic binders in the intermediate slurry is preferably 50 to 60 wt%, specifically 50 w...

Embodiment 1

[0045] It is made of the following raw materials in parts by weight: 40 parts by weight of ball-milled ceramic fiber, 10 parts by weight of organic binder, 30 parts by weight of inorganic binder, and 20 parts by weight of organic fiber. Among them, the average diameter of the ball-milled ceramic fiber is 2 μm, the length is 30 μm, and the chemical composition: the content of alumina is 50wt%, and the combined amount of alumina and silicon dioxide is 98.5wt%. The organic binder is corn starch produced by Linyi Hengyuan Industrial Co., Ltd.; the inorganic binder The silica sol produced by Linyi Kehan Silicon Products Co., Ltd., the solid content of the silica sol is 30wt%; the organic fiber is the polypropylene fiber produced by Langfang Shuiteng Chemical Co., Ltd., the fiber length is 6mm, and the fiber number average molecular weight is 20-25 Ten thousand.

[0046] Concrete preparation method comprises the following steps:

[0047] (1) Put the ball-milled ceramic fiber, org...

Embodiment 2

[0053] It is made of the following raw materials in parts by weight: 50 parts by weight of ball-milled ceramic fiber, 8 parts by weight of organic binder, 25 parts by weight of inorganic binder, and 17 parts by weight of organic fiber. Among them, the average diameter of the ball-milled ceramic fiber is 4 μm, the length is 60 μm, the chemical composition: the content of alumina is 48wt%, and the combined amount of alumina and silicon dioxide is 99wt%; the organic binder is carboxymethyl cellulose produced by Yibo Chemical Co., Ltd. in Dacheng County; The inorganic binder is the aluminum sol produced by Zibo Jinqi Chemical Co., Ltd., and the solid content of the aluminum sol is 25wt%. The organic fiber is the polyester fiber produced by Nantong Huatong Fiber Company. 25,000.

[0054] Concrete preparation method comprises the following steps:

[0055] (1) Put ball-milled ceramic fiber, organic fiber and organic binder into a mixer pre-injected into water, and turn on the mixer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com