Preparation method of styrene and methyl methacrylate copolymerized magnetic oil absorbing material

A methyl methacrylate, styrene technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as being unsuitable for large-scale production, unsuitable for recycling, and complex experimental procedures, and achieve good lipophilicity and protection. The effect of oil performance, high yield, and simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of styrene and methyl methacrylate copolymerized magnetic oil-absorbing material

[0026] Sequentially weigh and weigh 0.3g250nm Fe 3 o 4 , 10ml of oleic acid in a three-necked flask, heated and stirred at 80°C for 1h, so that oleic acid can fully modify Fe 3 o 4 ; then add 2g styrene, 2g methyl methacrylate, 0.4g divinylbenzene, and continue to stir for 5 minutes; then weigh 1g PEG1000 and add it into 100ml deionized water, ultrasonically oscillate until dissolved, then add it to a three-necked flask and stir at 60°C Heat for half an hour; finally weigh 1g of benzoyl peroxide, dissolve it in 20ml of ethanol, and put it into a three-neck flask after dissolving; finish the reaction after 4 hours at 80°C, wash it with water and ethanol three times, and dry it in an oven at 40°C for later use .

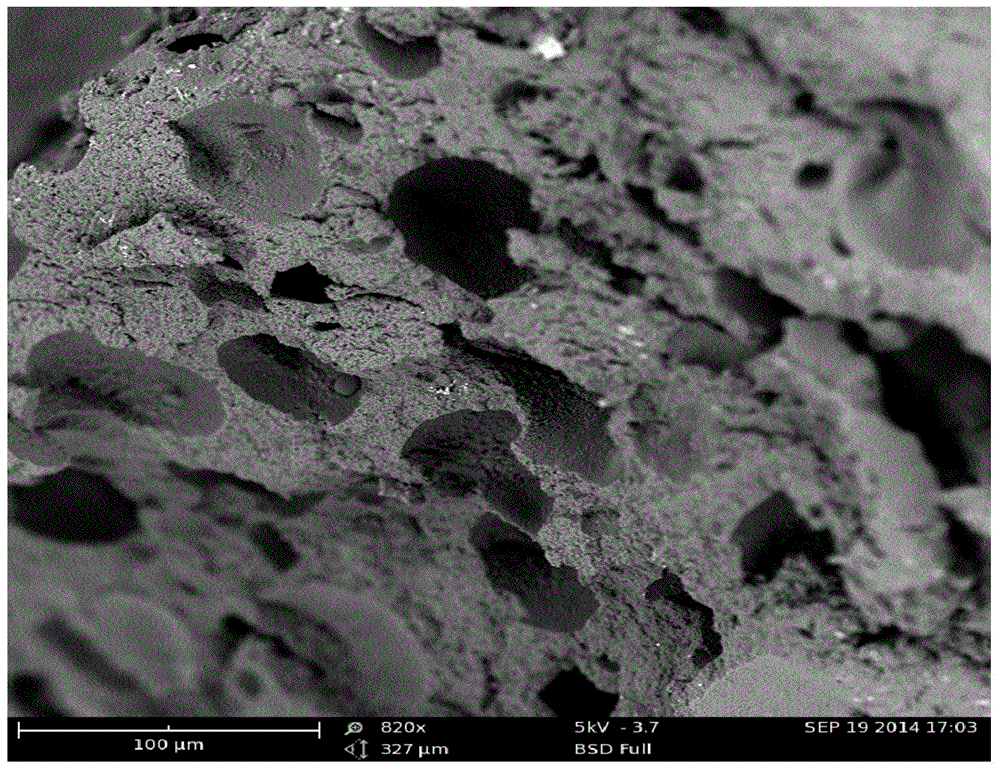

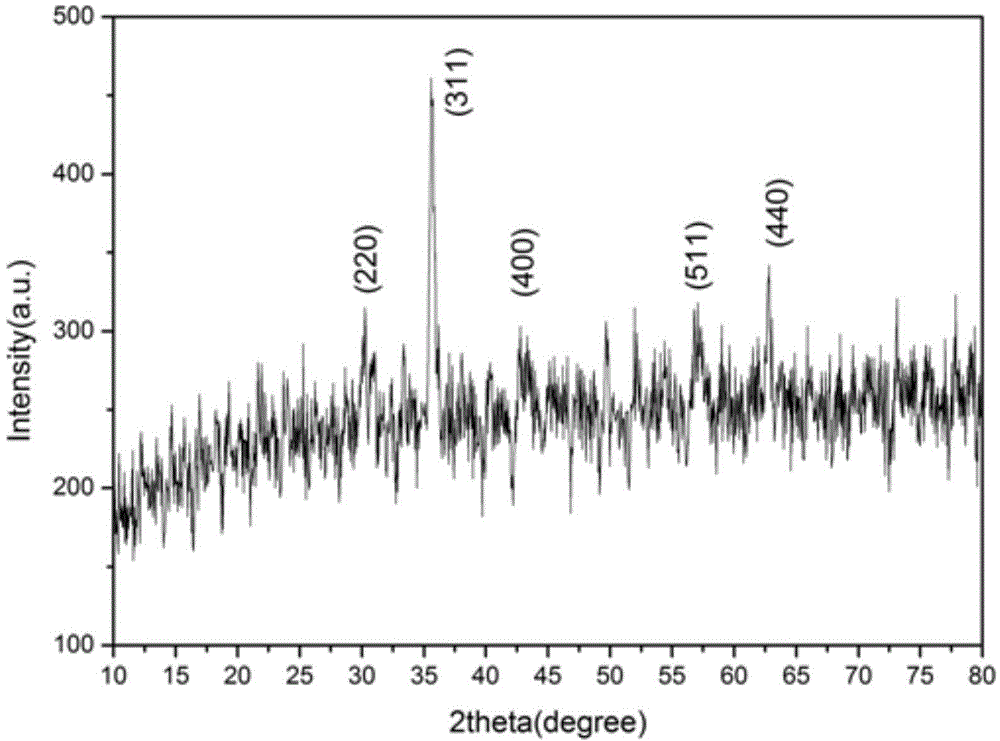

[0027] Such as figure 1 As shown, the styrene and methyl methacrylate copolymerized magnetic oil-absorbing materials prepared in Example 1 are respecti...

Embodiment 2

[0028] The styrene and methyl methacrylate copolymerized magnetic oil-absorbing material obtained in Example 1 was tested for the adsorption performance of diesel oil. Specific test method: in a surface area of 170cm 2 Inject a certain amount of deionized water into the watch glass, and then use a graduated cylinder to measure 4ml diesel oil on the water surface to simulate a thin layer of oil film on the water surface. Put 0.5g of oil-absorbing material on the oily surface, and the diesel oil quickly soaks the oil-absorbing material until it reaches adsorption saturation. Finally, the oil-absorbing material was taken out and weighed, and the measured oil absorption was 3.1 g / g. Adsorption ratio = (total mass of material after oil absorption - mass of adsorbent material) / mass of adsorbent material Regeneration method of oil absorbing material: ethanol as solvent, and diesel oil in the material is extracted after ultrasonic oscillation. The material is then drawn away from...

Embodiment 3

[0031] Example 3: Preparation of styrene and methyl methacrylate copolymerized magnetic oil-absorbing material

[0032] Sequentially weigh and weigh 0.3g250nm Fe 3 o 4 , 10ml of oleic acid in a three-necked flask, heated and stirred at 80°C for 1h to fully modify Fe3O4 with oleic acid; then add 2g of styrene, 2g of methyl methacrylate, 0.4g of divinylbenzene, and continue stirring for 5min; then weigh 0.5 Add g PEG1000 into 100ml of deionized water, oscillate ultrasonically until dissolved, then add to a three-necked flask, stir, and heat at 60°C for half an hour; finally weigh 1g of benzoyl peroxide, dissolve it in 20ml of ethanol, dissolve and add to the three-necked flask; After 6 hours of reaction at 80°C, it was finished, washed three times with water and ethanol, and dried in an oven at 40°C for later use.

[0033] The styrene and methyl methacrylate copolymerized magnetic oil-absorbing material obtained in Example 3 was tested for the adsorption performance of diesel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com