Distance adjustable ink jet type digital printer

An inkjet and adjustable technology, applied in printing and other directions, can solve the problems of easy hardening of inkjet materials, less inkjet materials, and easy changes, etc., to achieve the effect of rich colors, maintaining inkjet state, and preventing hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

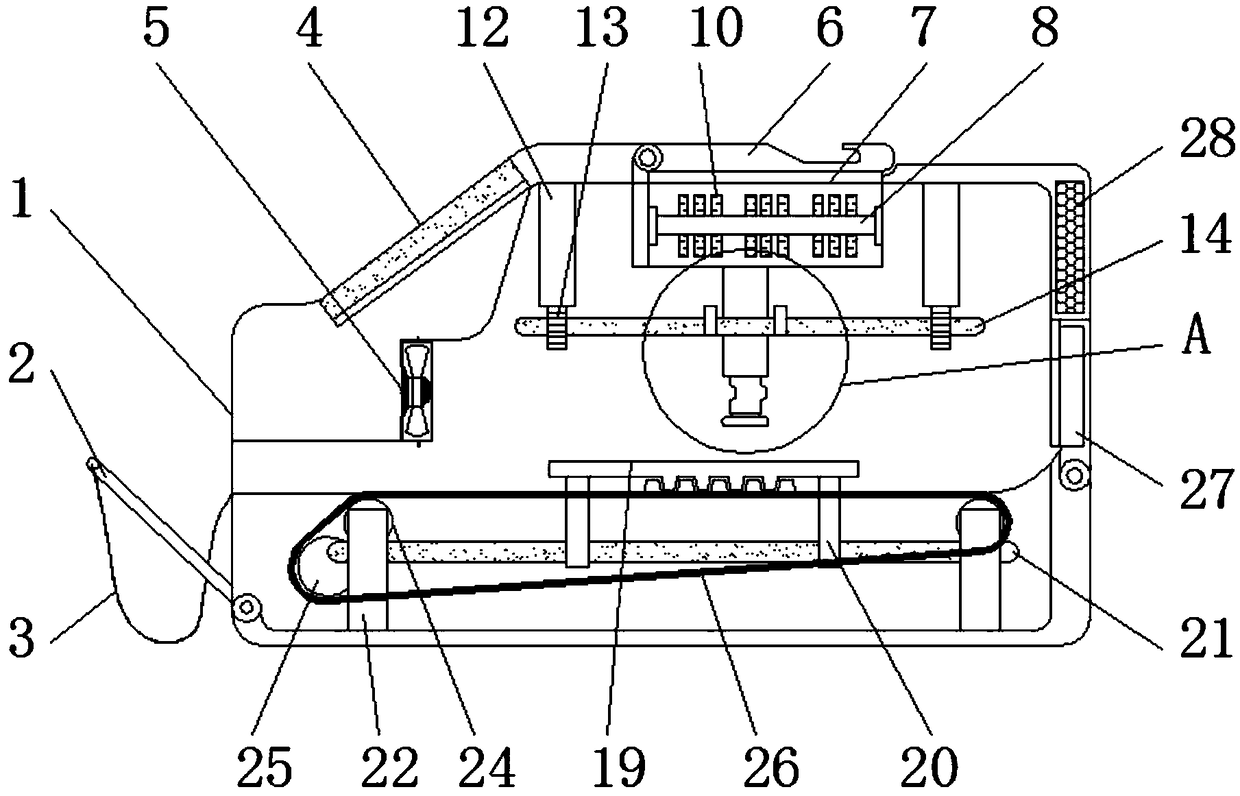

[0025] Example 1, such as figure 1 The middle maintenance net 3 can expand the maintenance net 3 to form an arc-shaped pocket structure through the rotation of the maintenance rod 2 on the body 1, which is convenient for collecting and stacking the printed materials inside the maintenance net 3, and the fan 5 It is set at the same horizontal position as the nozzle 18, and the air outlet net 28 is arranged at the right end of the body 1, so that the impurities in the air between the nozzle 18 and the material can be blown out of the air outlet net 28, so that the inkjet is cleaner and the quality of the printed material is better. high;

Embodiment 2

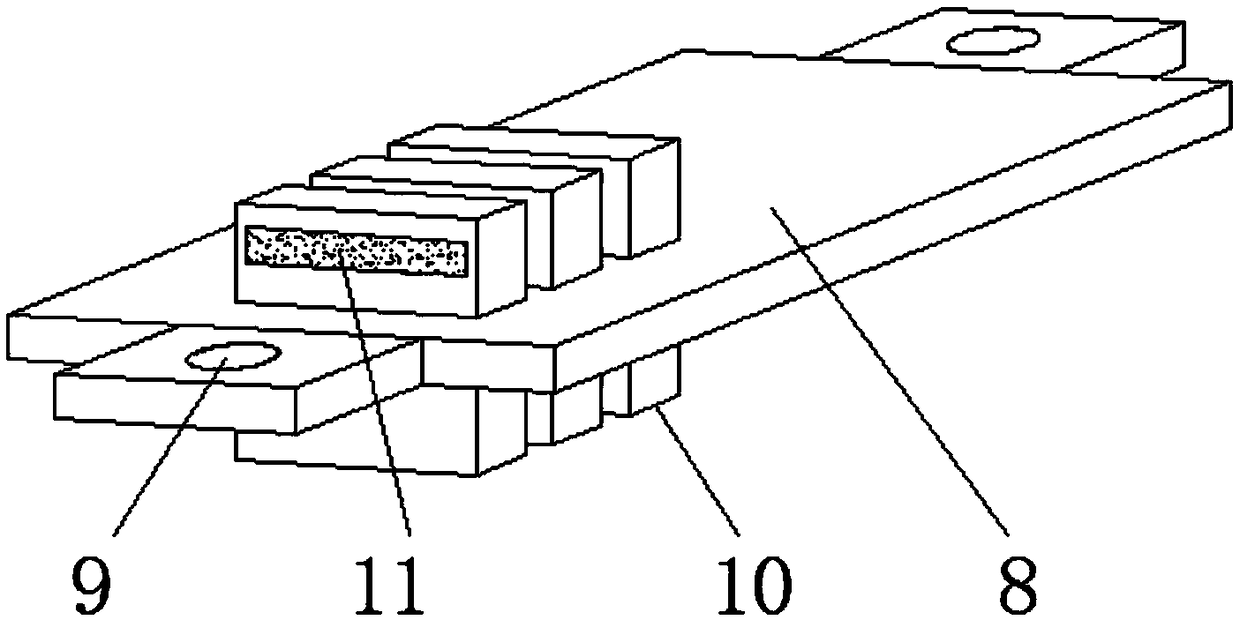

[0026] Example 2, such as figure 2 The mounting plate 8 is arranged inside the holding tank 7 to form a device for storing ink, and the inkjet material storage box 10 is snapped into the inside of the mounting plate 8. There are 3 groups respectively, and each group has three boxes. Printing inks of different colors are convenient for dismounting the installation plate 8 from the inside of the storage tank 7, and replacing the used inkjet material storage box 10, and through the function of the cover plate 6, it is possible to prevent the storage tank 7 from It is also convenient to observe the consumption situation in the inkjet material storage box 10 without entering dust;

Embodiment 3

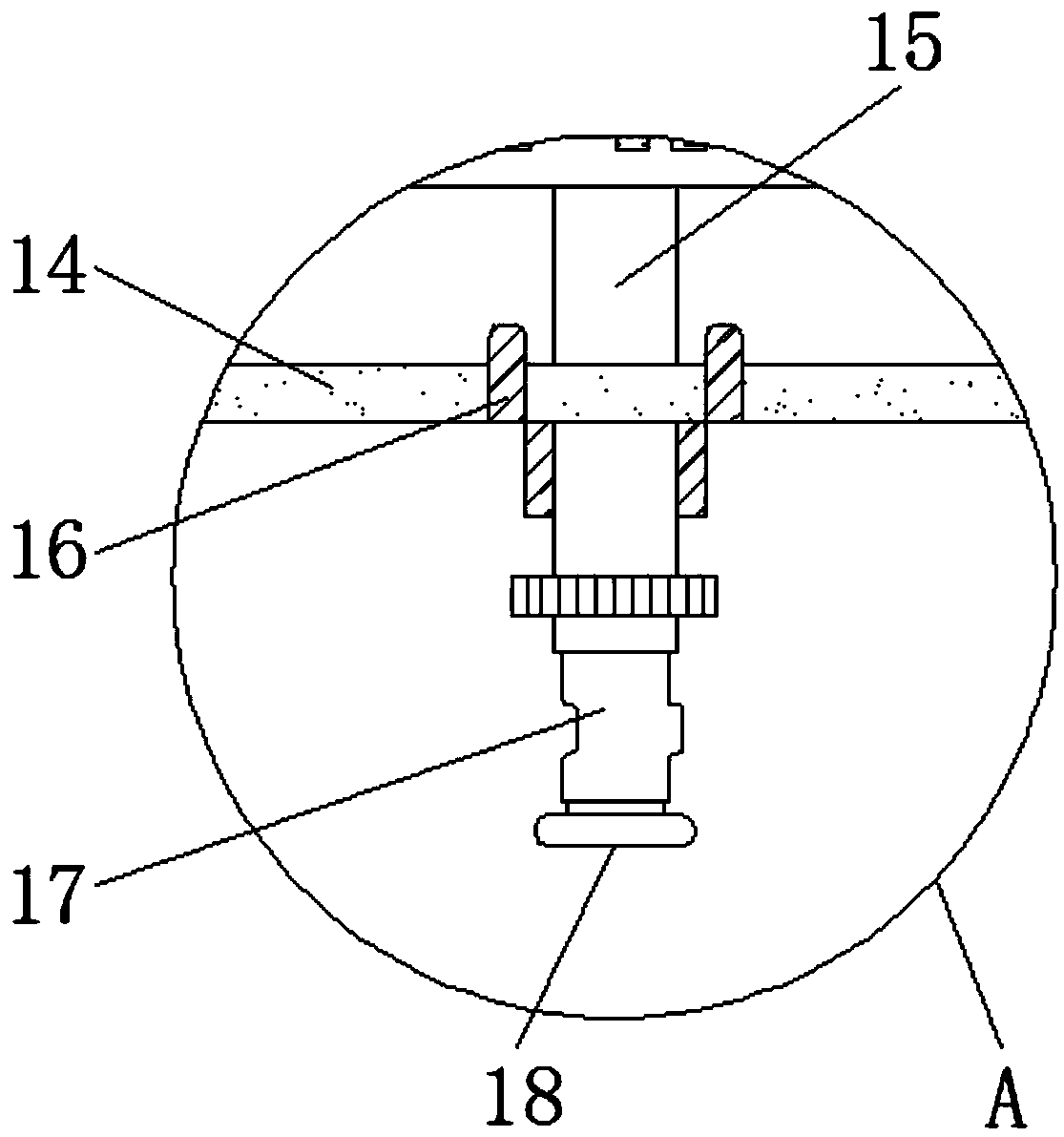

[0027] Example 3, such as image 3 The middle ink outlet rod 15 is a sliding structure on the suspension rod 14 through the first slider 16, which is convenient for moving the position of the nozzle 18, and the suspension rod 14 and the lifting rod 12 form a lifting structure in the body 1, which is convenient for adjusting the relationship between the nozzle 18 and the material. The distance between the spray head 18 and the material is always kept at an optimal inkjet distance of 2 mm, such as Figure 4 with Figure 5 Through the action of the thermistor 1701, the heating element 1704 inside the heat transfer cover plate 1705 is heated up, so that the ink passing through the ink cartridge 1702 and the flow channel 1703 maintains a relatively stable temperature, so that the ink of the same temperature can be ejected through the nozzle 18 every time. Make the quality of different positions of the material the same and uniform;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com