Patents

Literature

34results about How to "Adjustable specific surface area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of carbon aerogel fibers

ActiveCN106012107ASolve difficult to fiber problemsGood flexibilityArtificial filaments from cellulose solutionsWet spinning methodsNitrogenCellulose fiber

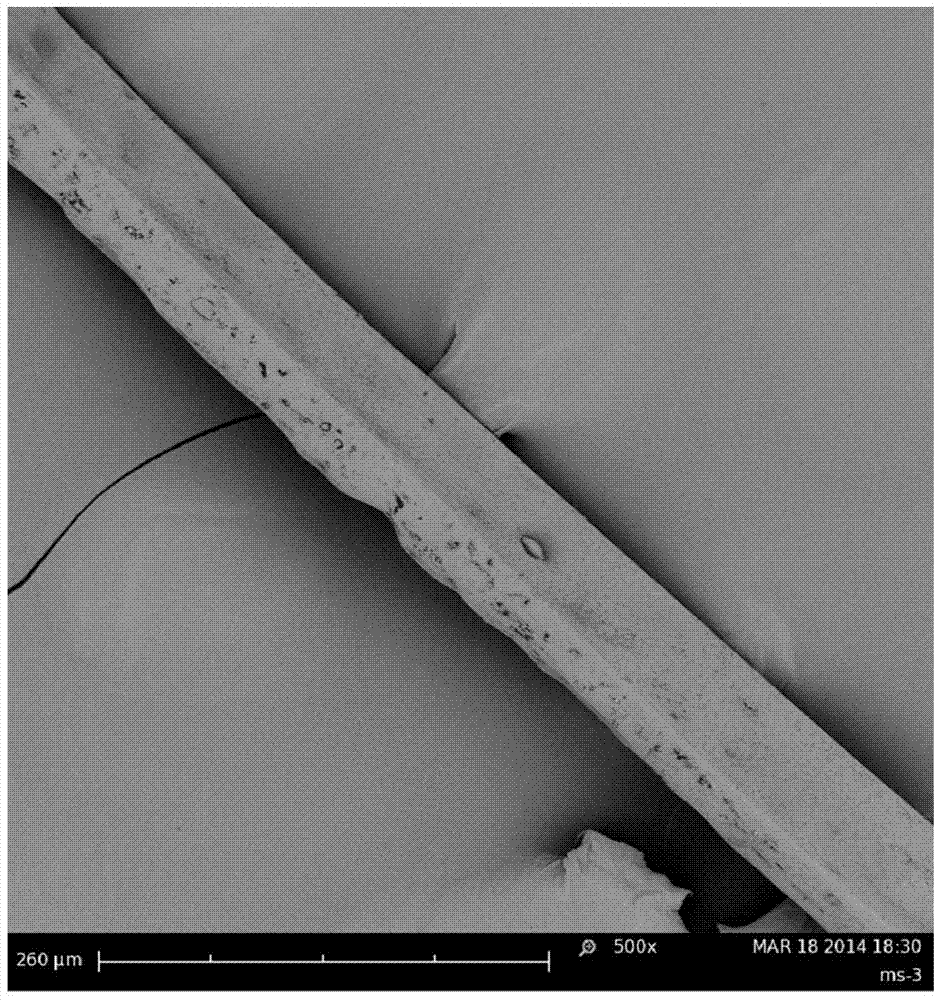

The invention provides a preparation method of carbon aerogel fibers. The method comprises the following steps that a spinning stock solution is prepared; a coagulating bath is prepared; the spinning stock solution is added into the coagulating bath, wet spinning is conducted, and cellulose gel fibers are obtained; the cellulose gel fibers are subjected to winding and immersed into an ageing solution for normal temperature ageing for 15 min to 1 h, the aged cellulose gel fibers are washed to be neutral with deionized water, solvent replacement is conducted with deionized water or ethyl alcohol or tert butyl alcohol, drying is conducted, and cellulose aerogel fibers are obtained; the cellulose aerogel fibers are put into a tubular furnace to be carbonized in a nitrogen environment, and the carbon aerogel fibers are obtained. The preparation method of the carbon aerogel fibers has the advantages that the raw materials are wide in resource, low in price and easy to obtain, the preparation process is simple, the spinnability is good, and the method is green and environmentally friendly, and the problem that a carbon aerogel cannot form fibers easily is solved.

Owner:DONGHUA UNIV

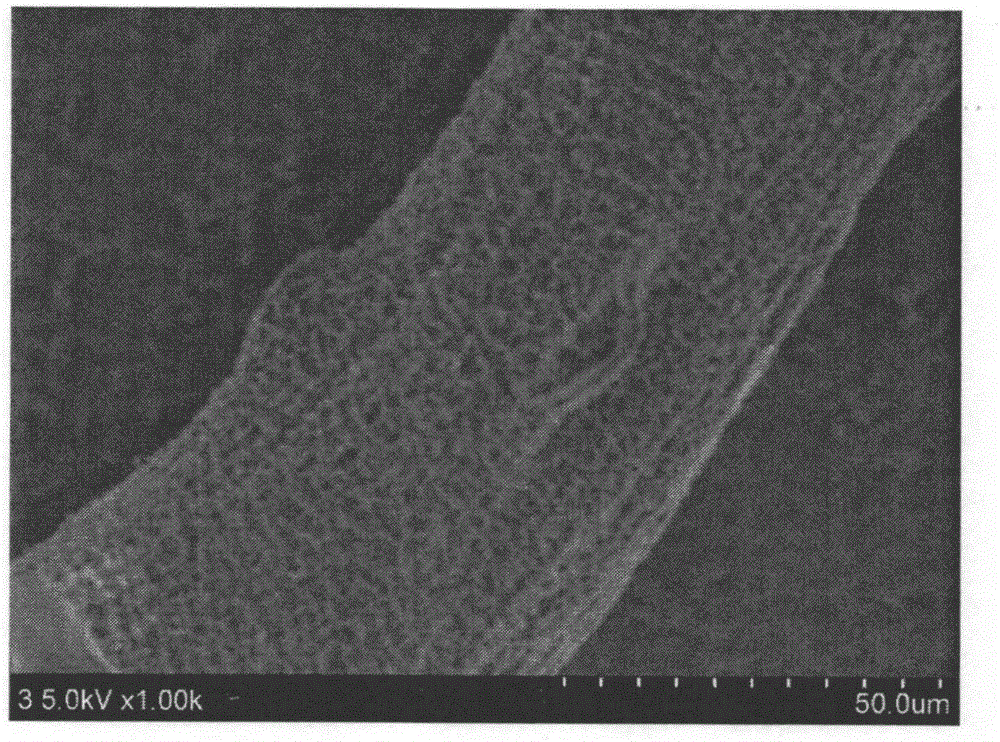

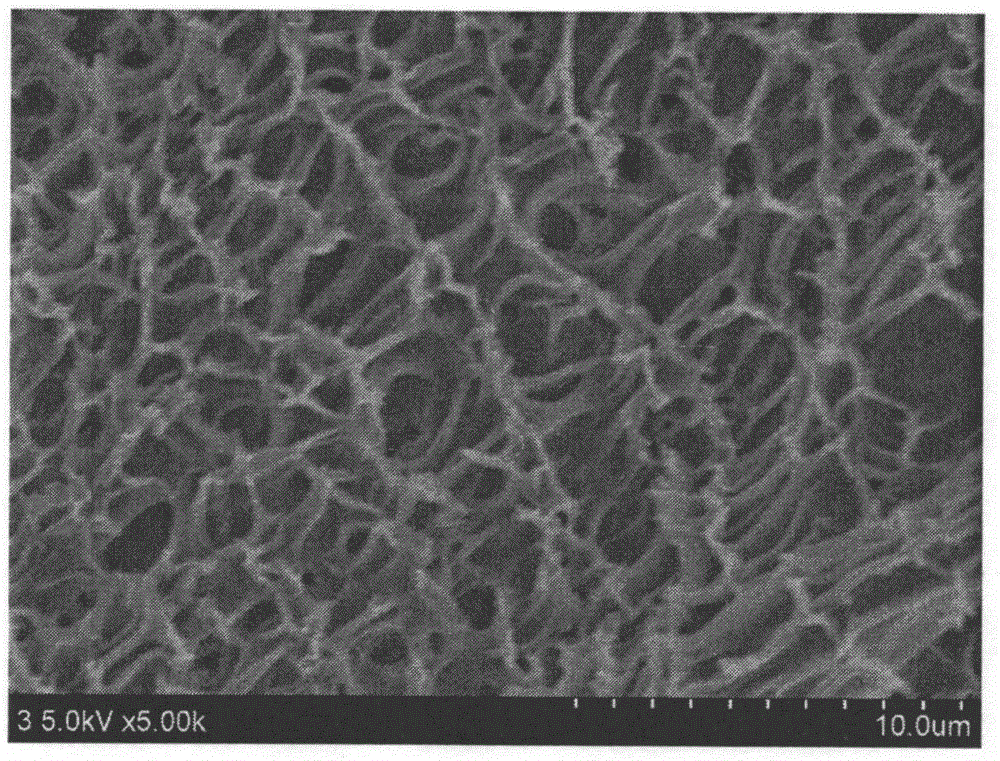

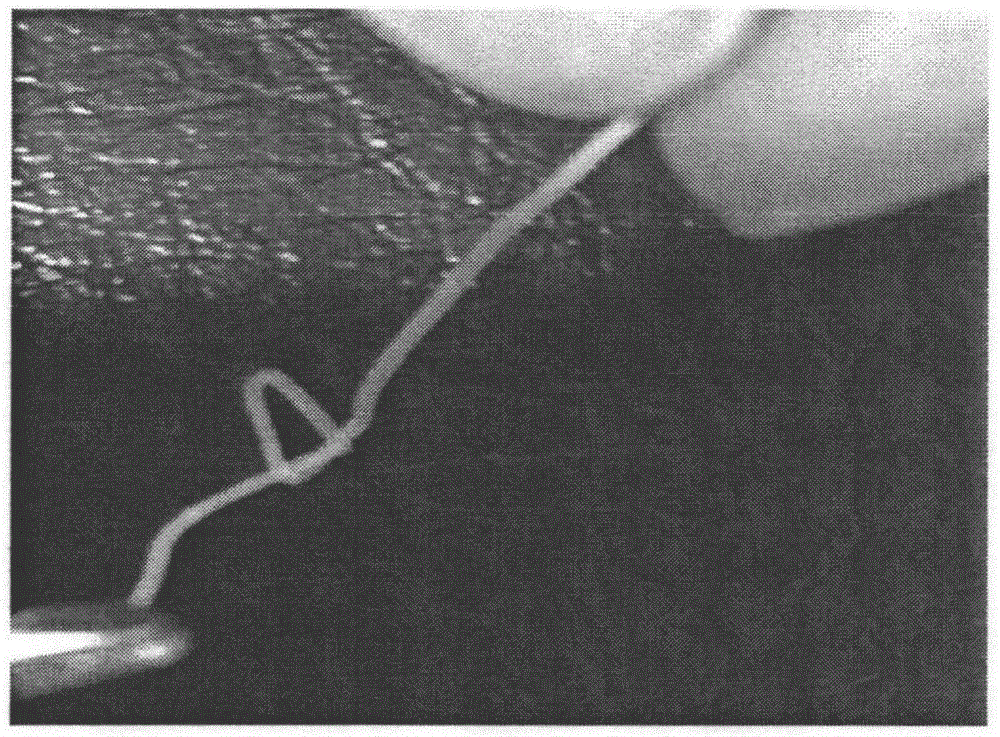

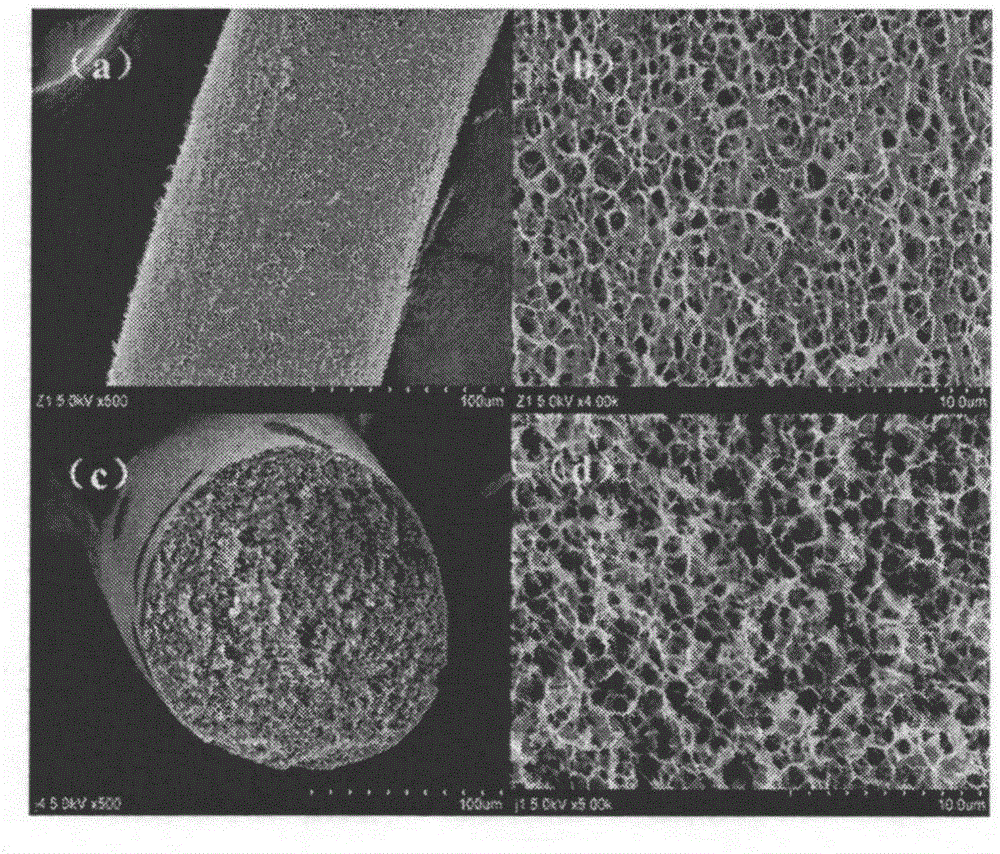

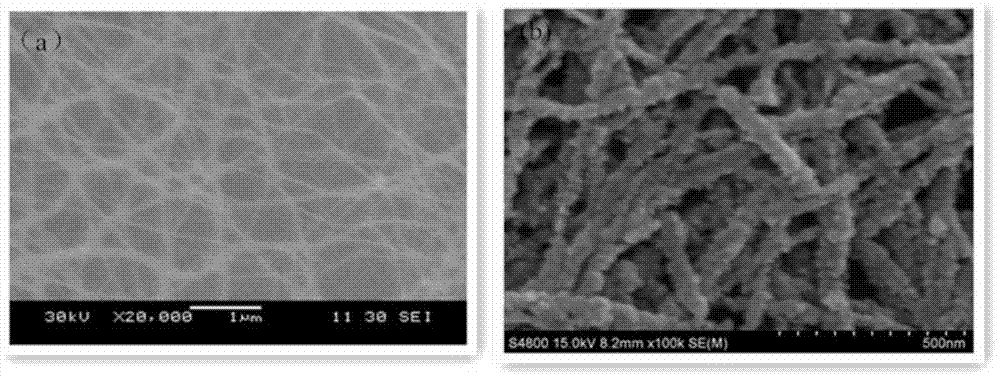

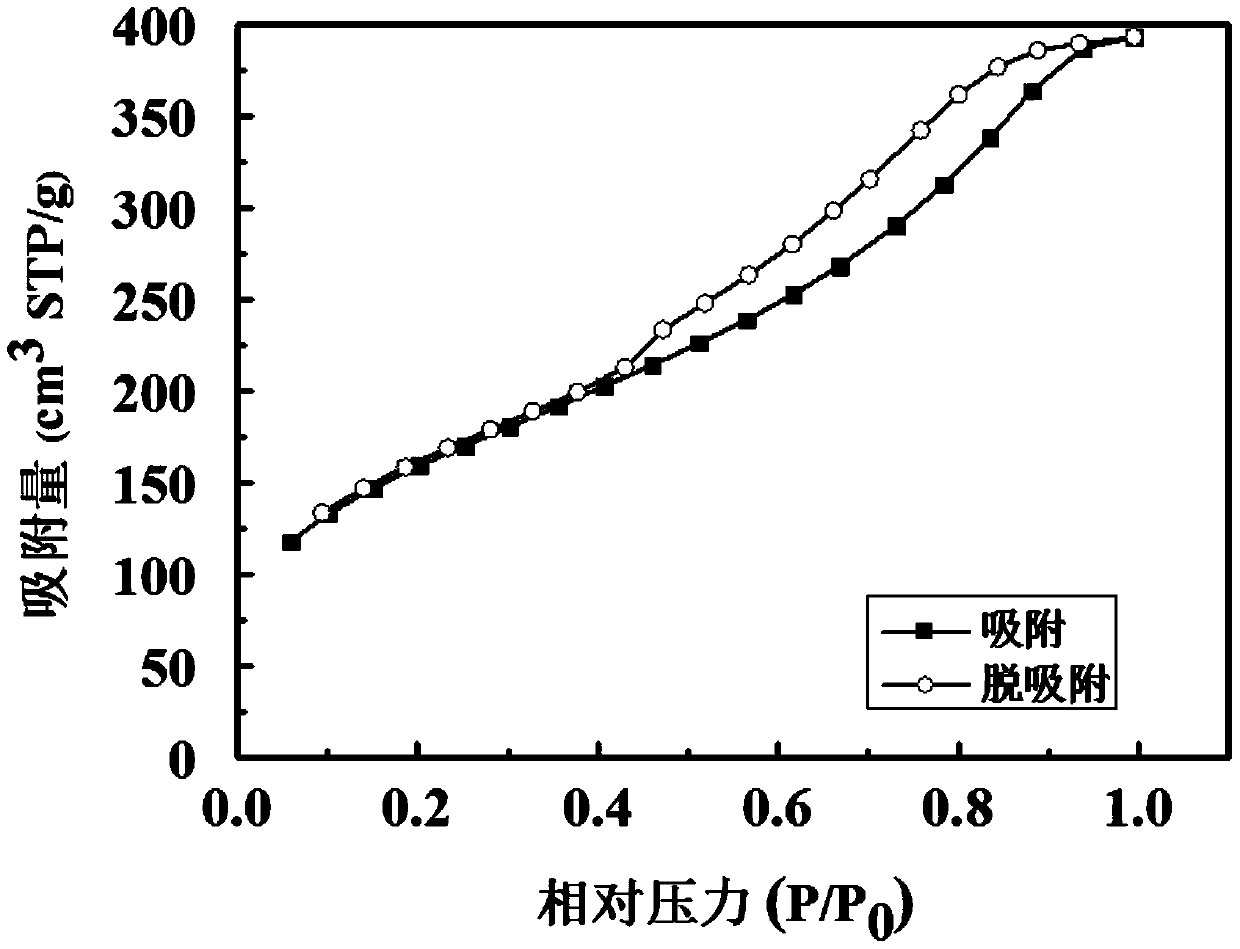

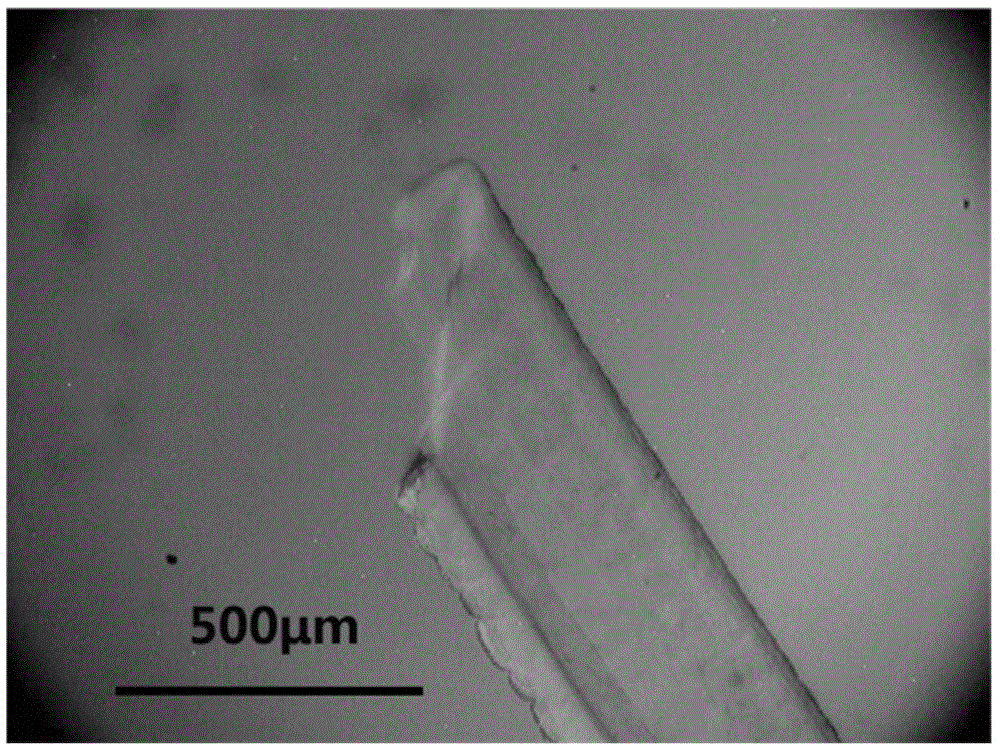

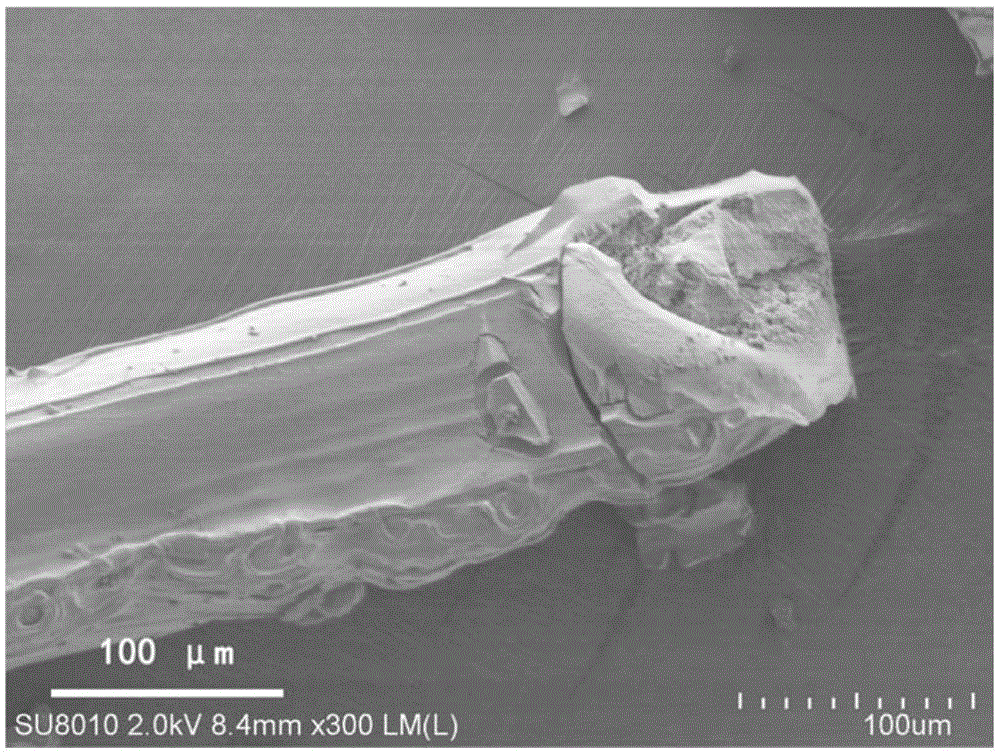

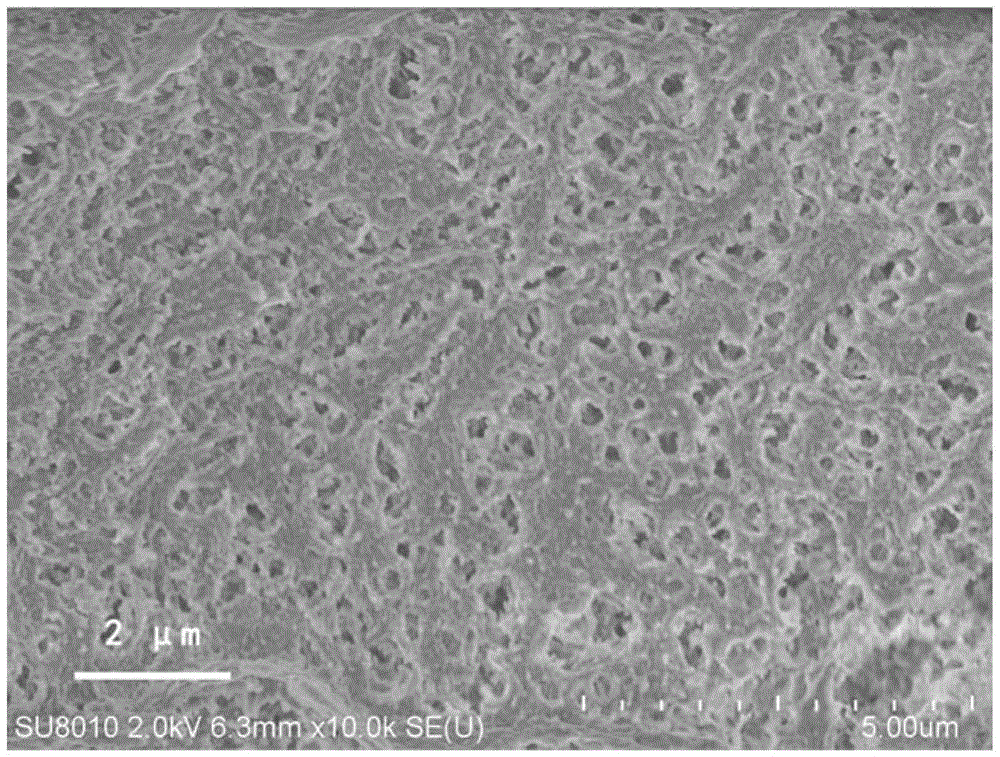

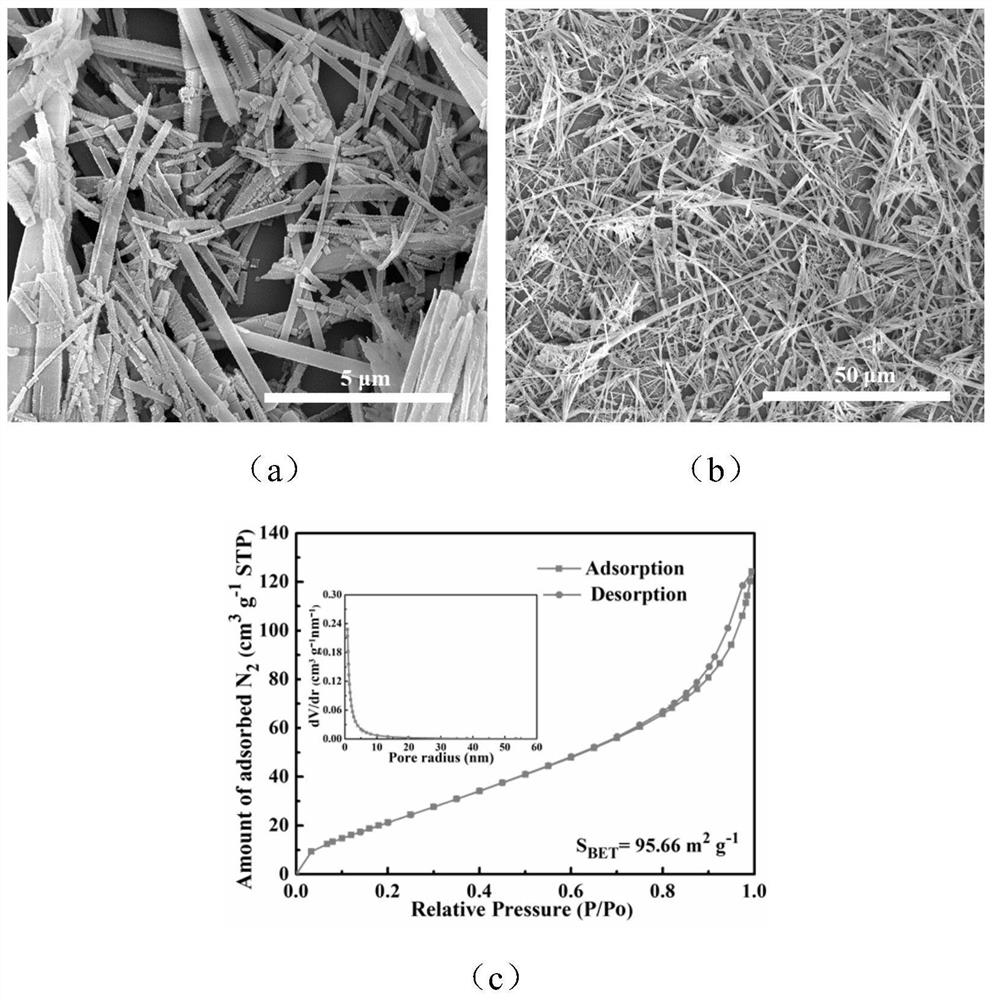

Continuous cellulose aerogel fiber and preparation method thereof

ActiveCN105970325AAdjustable specific surface areaShorten the timeArtificial filaments from cellulose solutionsWet spinning methodsFiberPorosity

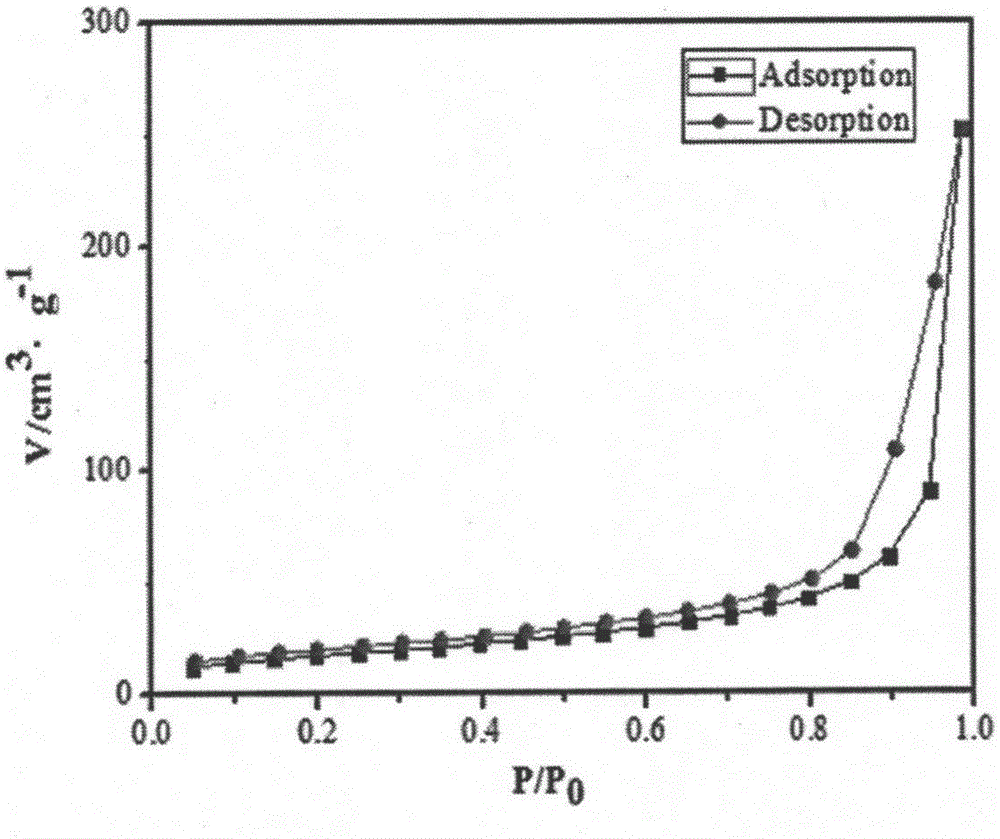

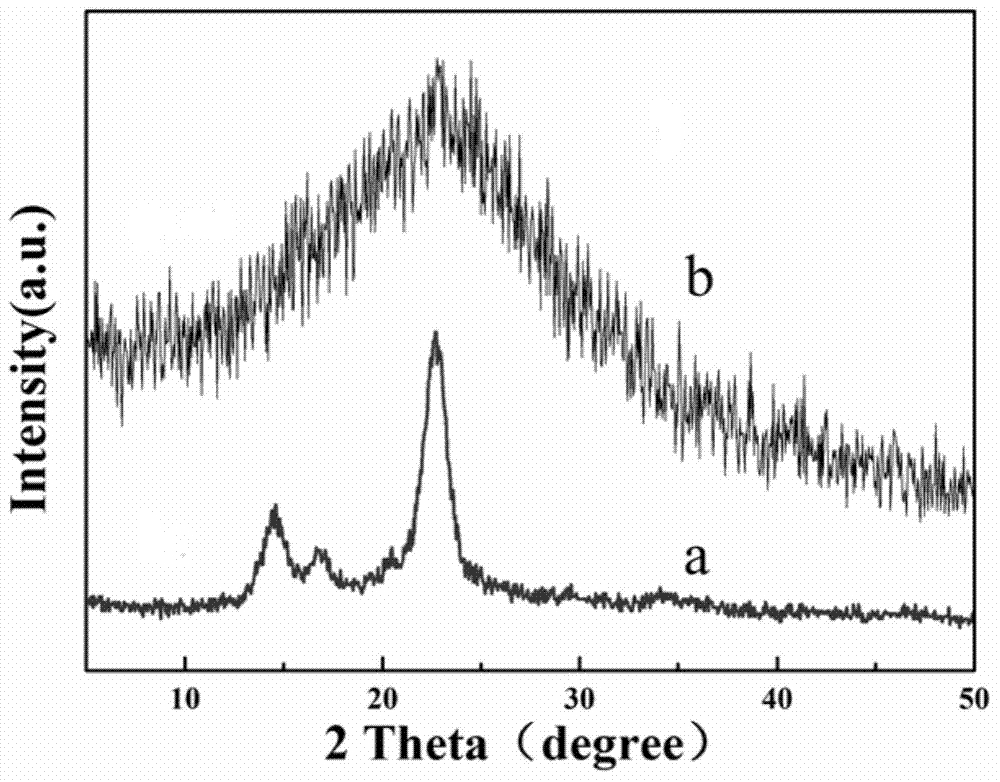

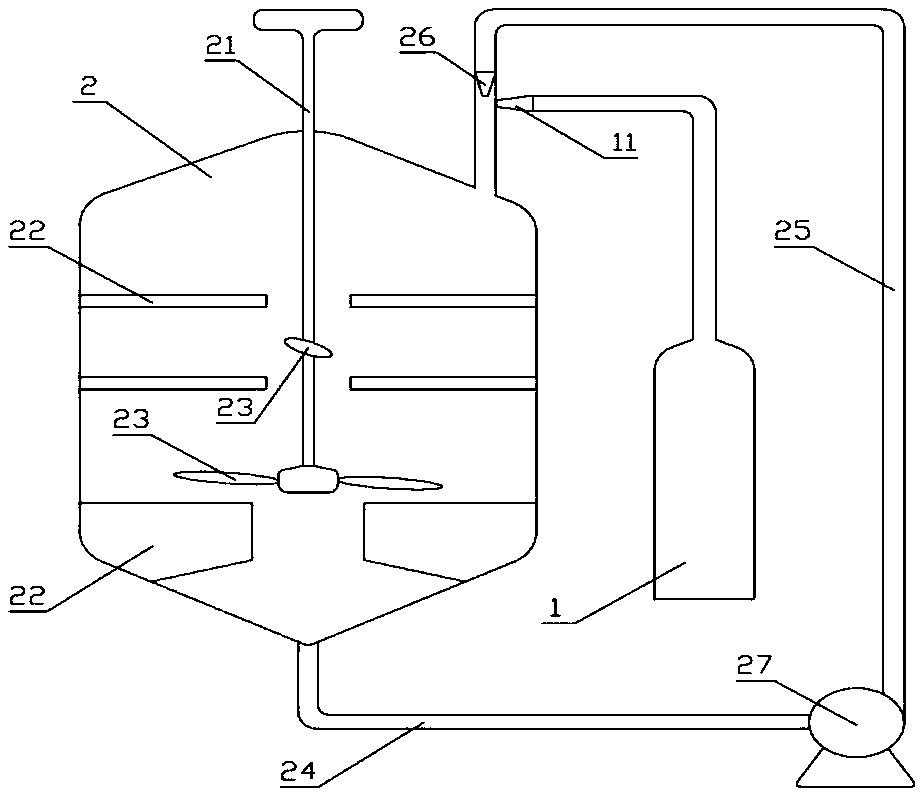

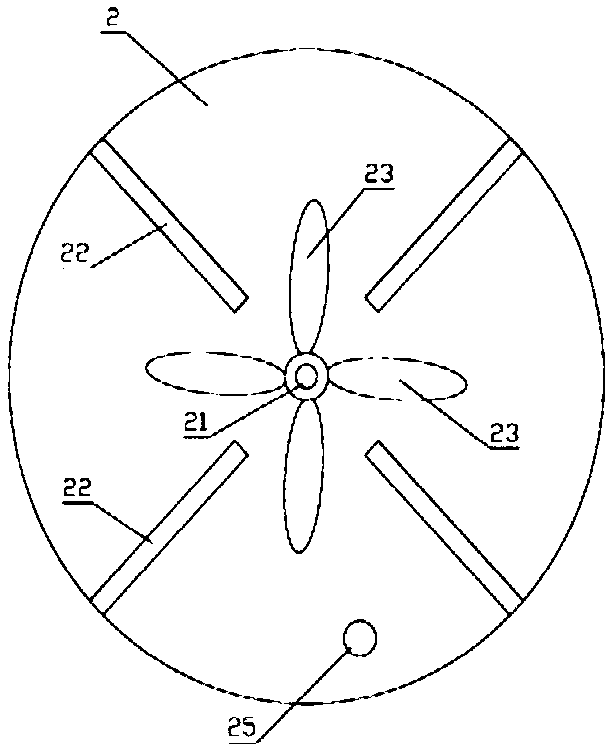

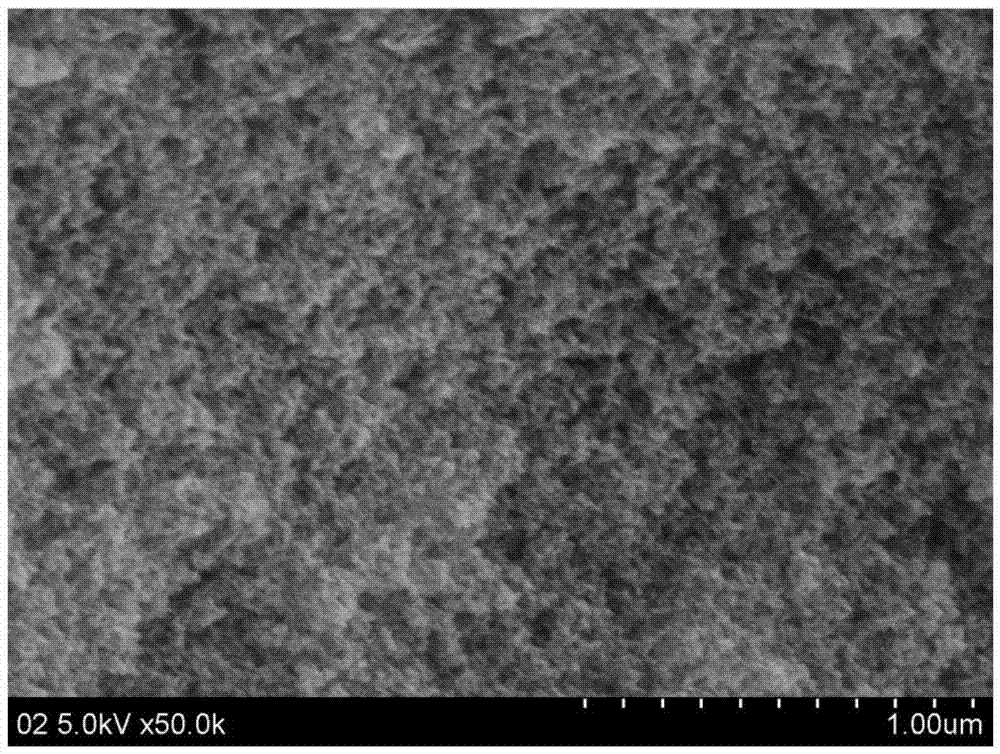

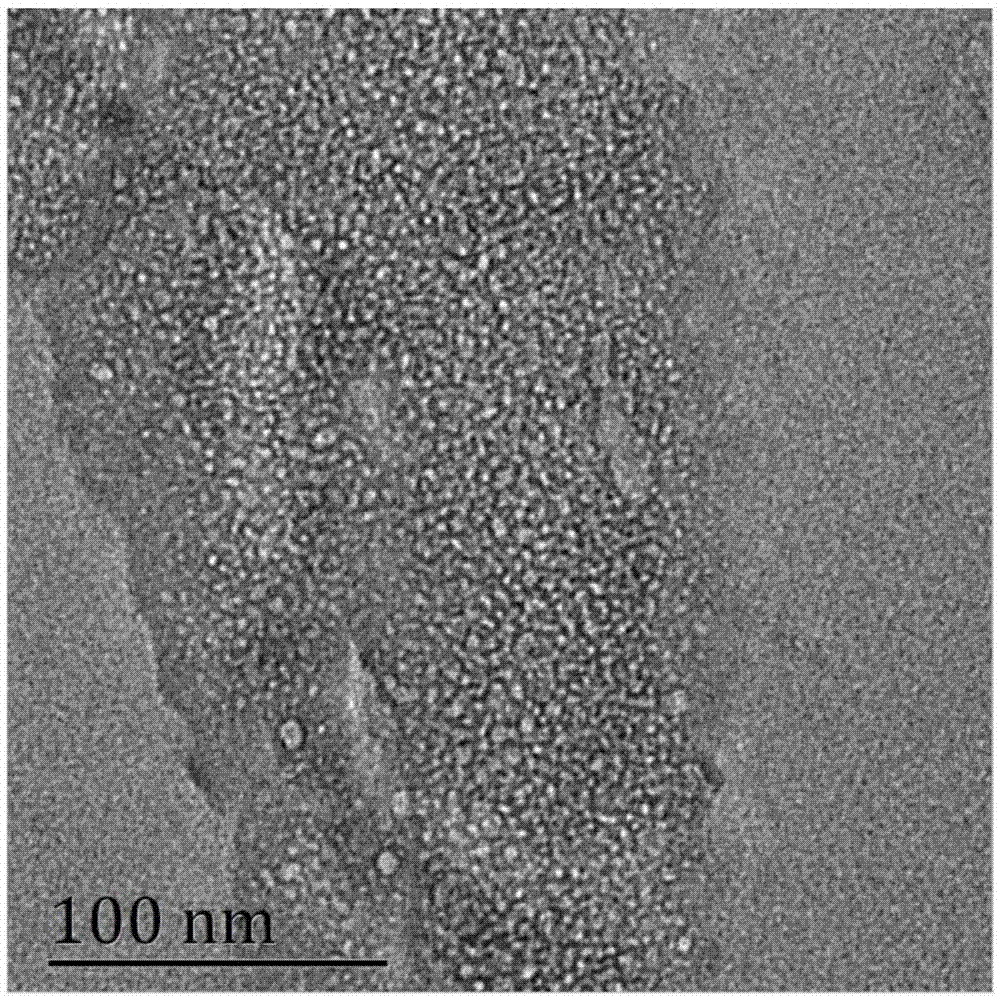

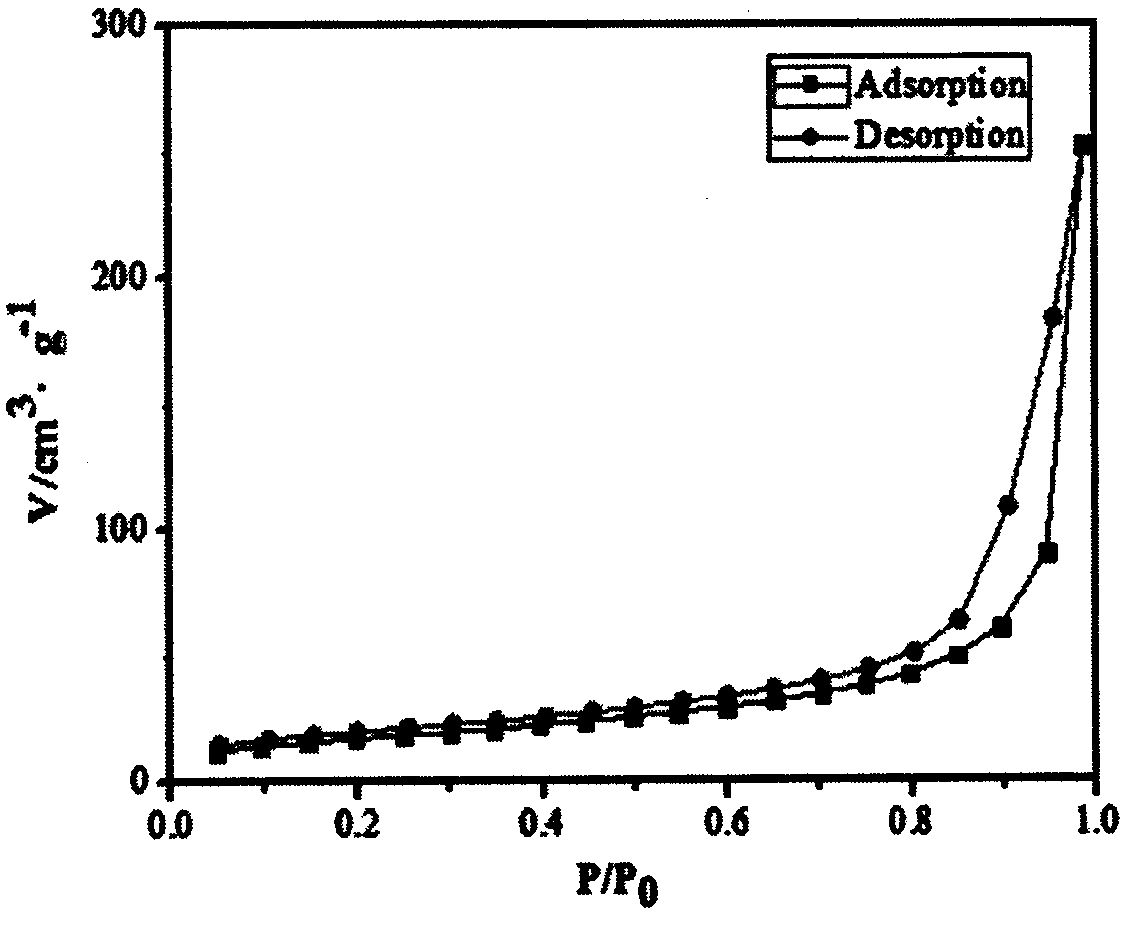

The invention provides a continuous cellulose aerogel fiber and a preparation method thereof. The preparation method comprises the following steps: dispersing cellulose into a dispersing agent so as to obtain a spinning stock solution; extruding the spinning stock solution into a coagulating bath for wet-method spinning so as to obtain cellulose aerogel fiber; winding the cellulose aerogel fiber in the coagulating bath, and soaking into an aging liquid for aging; washing the aged cellulose aerogel fiber till the pH is neutral, and drying, so as to obtain the continuous cellulose aerogel fiber. The preparation method provided by the invention has the characteristics that raw materials are cheap and easy to obtain, the preparation process is simple, green and pollution-free, the continuous cellulose aerogel fiber is good is spinnability, and the problem that cellulose aerogel is hard to spin into fiber is solved. The diameter of the cellulose aerogel fiber provided by the invention is smaller than 120 [mu]m, the cellulose aerogel fiber has the characteristics of high specific surface area (greater than or equal to 88m<2> / g), high porosity (greater than or equal to 85%), and low density (less than or equal to 0.2 / cm<3>), meanwhile the fiber specific surface area can be adjusted, and the cellulose aerogel fiber can be used in fields such as functional clothes, sensing, catalyst loading and adsorption filtration, cosmetics and biological treatment.

Owner:DONGHUA UNIV

Preparation method of ZIF complex based novel lithium ion battery cathode materials

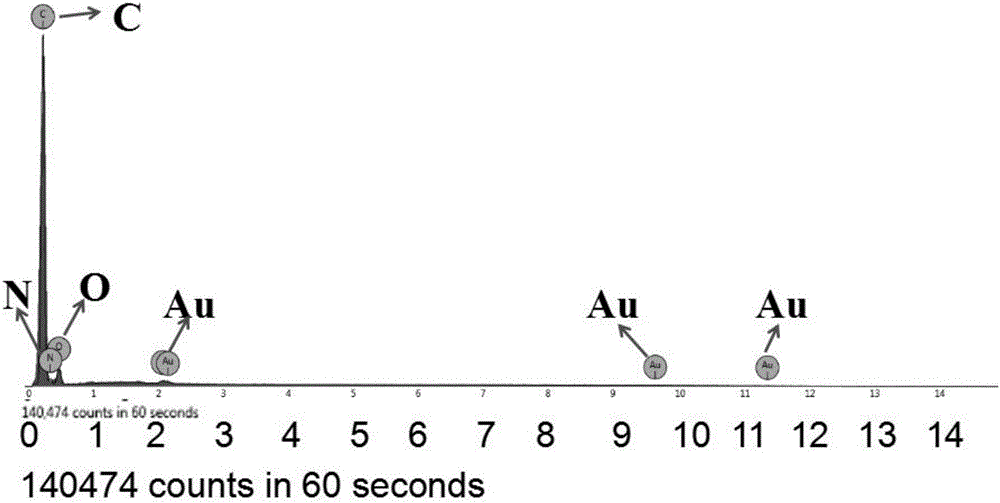

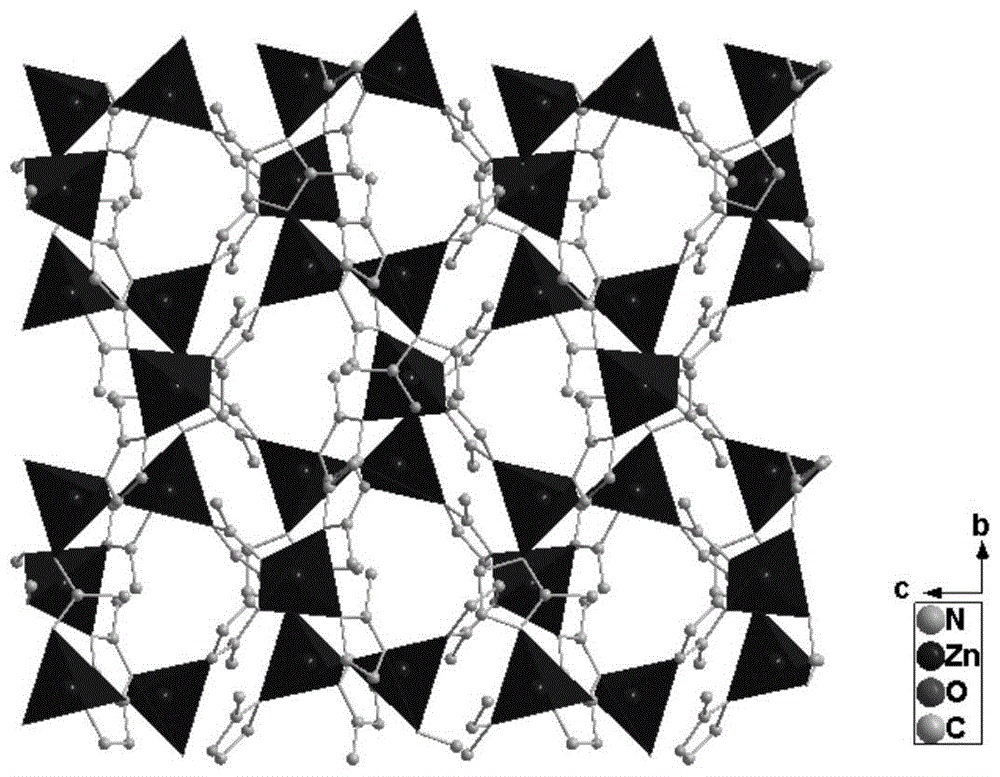

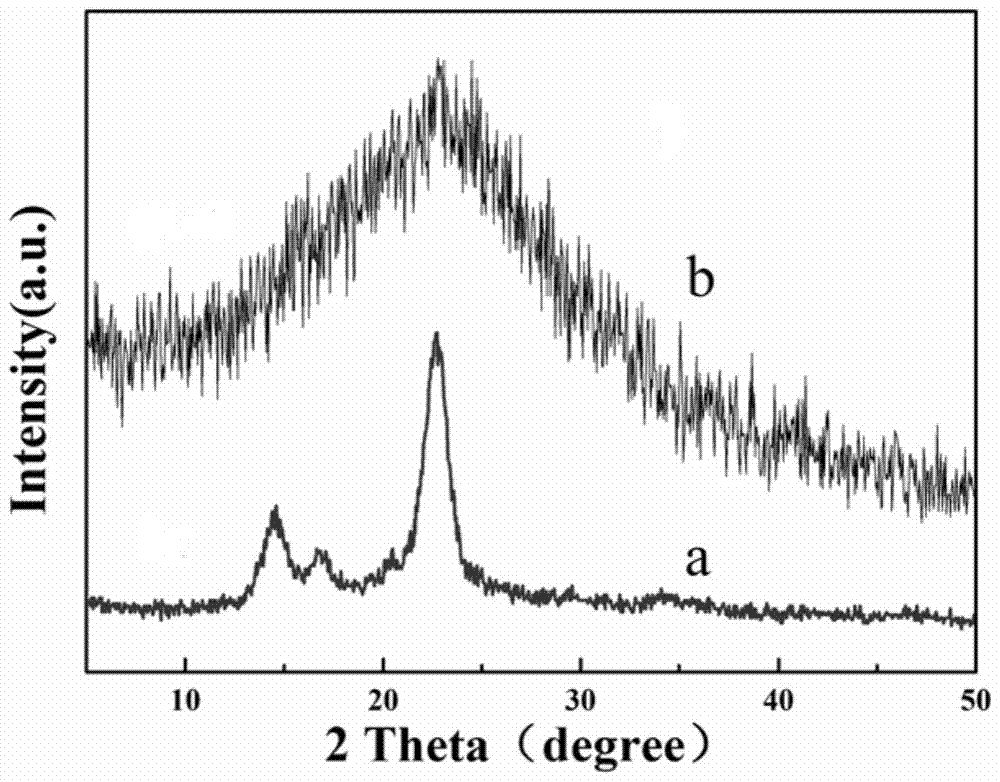

InactiveCN105762363APromote circulationImproved magnification performanceCell electrodesSecondary cellsPorous carbonCharge discharge

The invention discloses a preparation method of ZIF complex based novel lithium ion battery cathode materials.The preparation method has the advantages that a novel zeolitic imidazole organic framework compound is synthesized to prepare nitrogen-doped porous carbon materials which are applied to the lithium ion battery cathode materials, so that first specific discharge capacity reaches 1211 mAh / g, charge-discharge current density reaches 100 mA / g, and specific capacity is almost about 620 mAh / g (a theoretical value of commercial graphite cathode specific capacity reaching 372 mAh / g); even if the lithium ion battery cathode materials cycle for 100 times, good cycle performance can be demonstrated, and when current density reaches 1000 mAh / g, specific capacity can also reach 410 mAh / g, so that excellent rate performance can be demonstrated.

Owner:SOUTH CHINA NORMAL UNIVERSITY

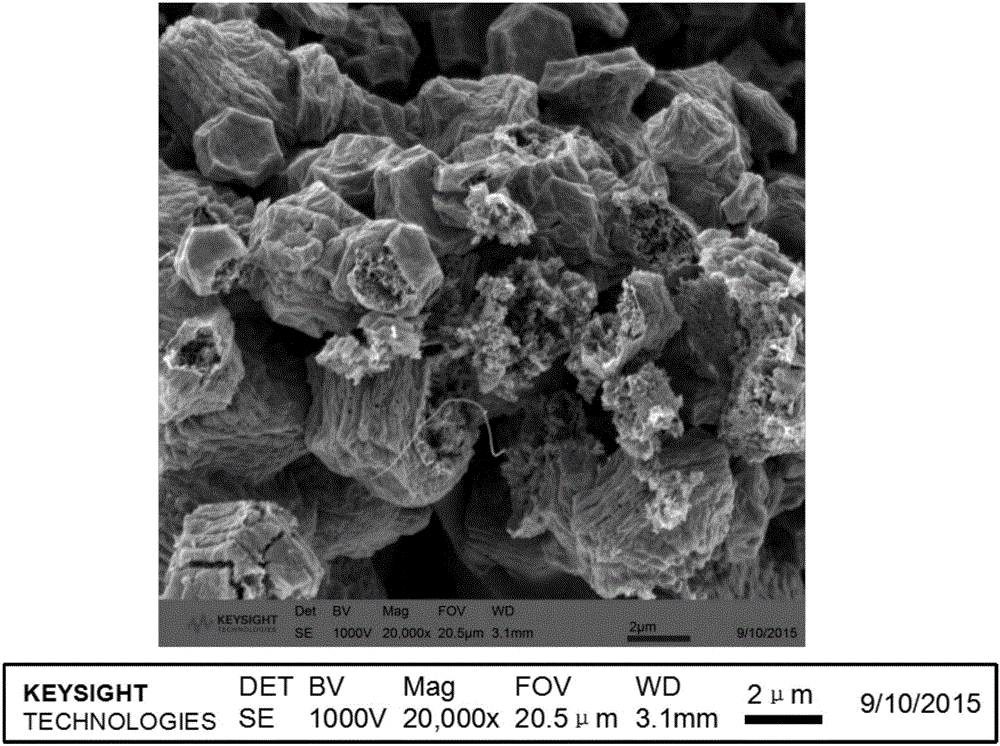

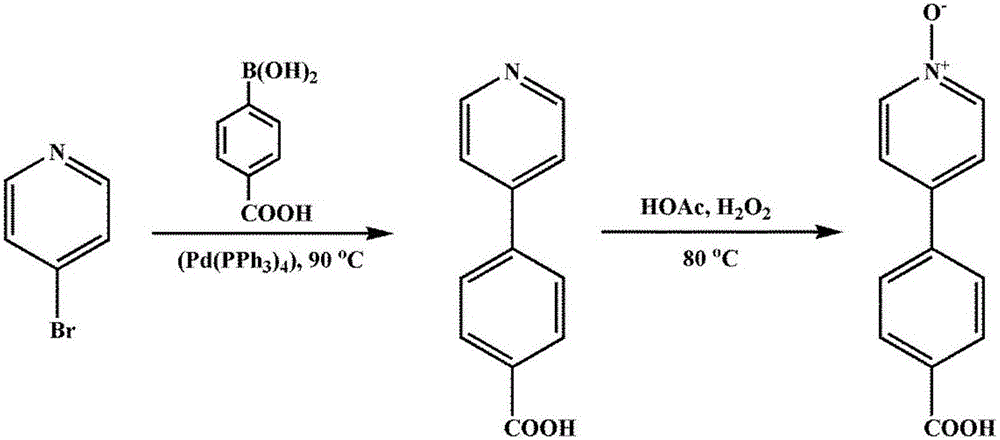

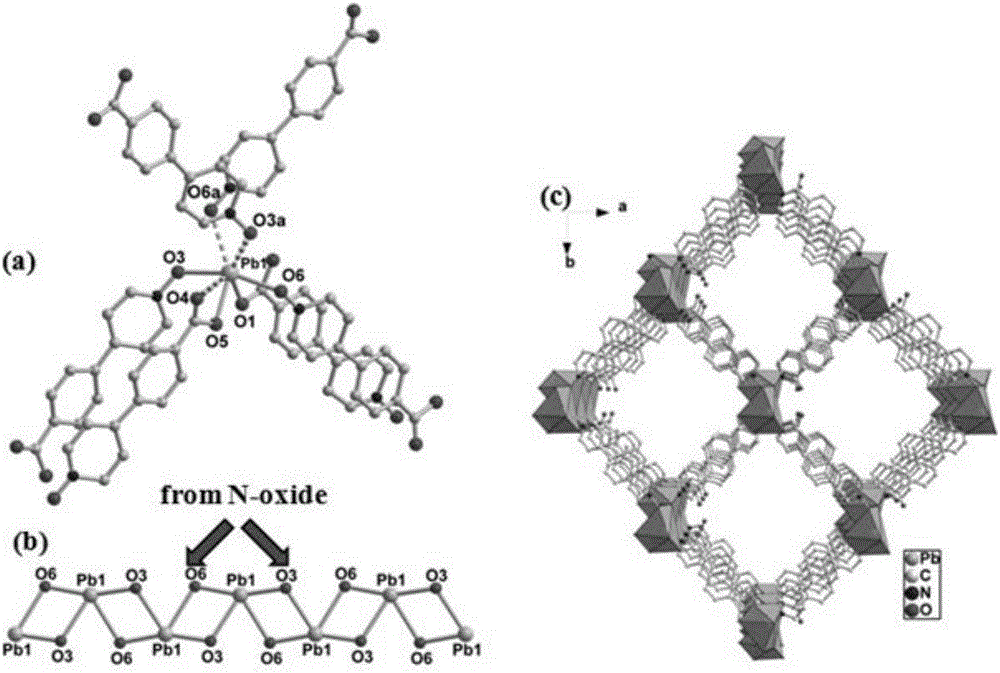

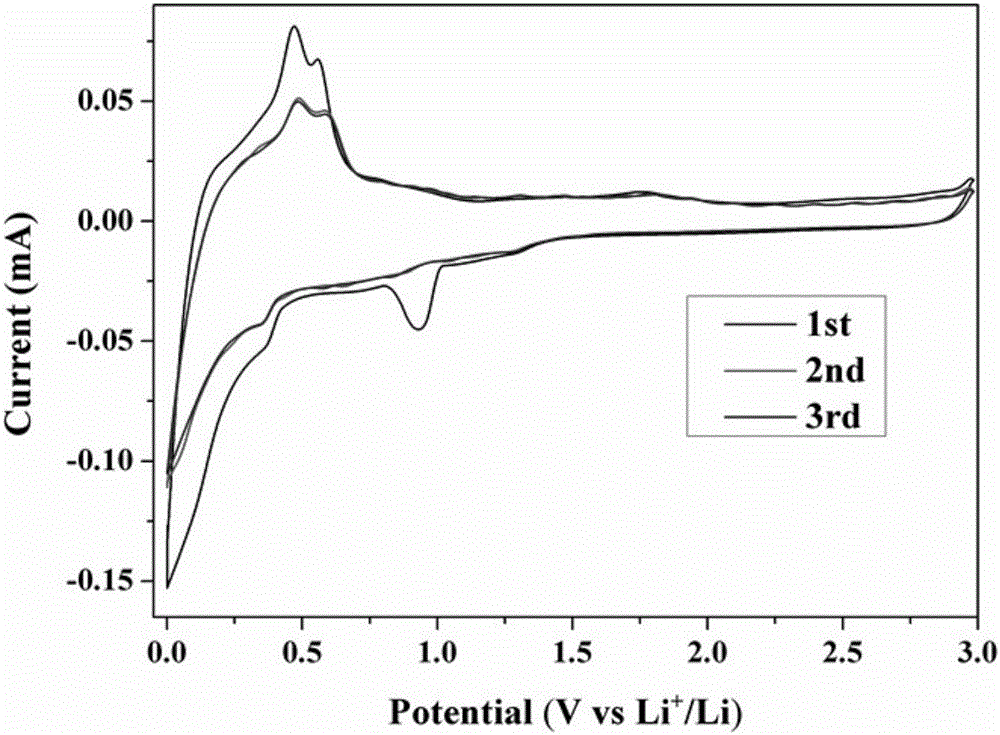

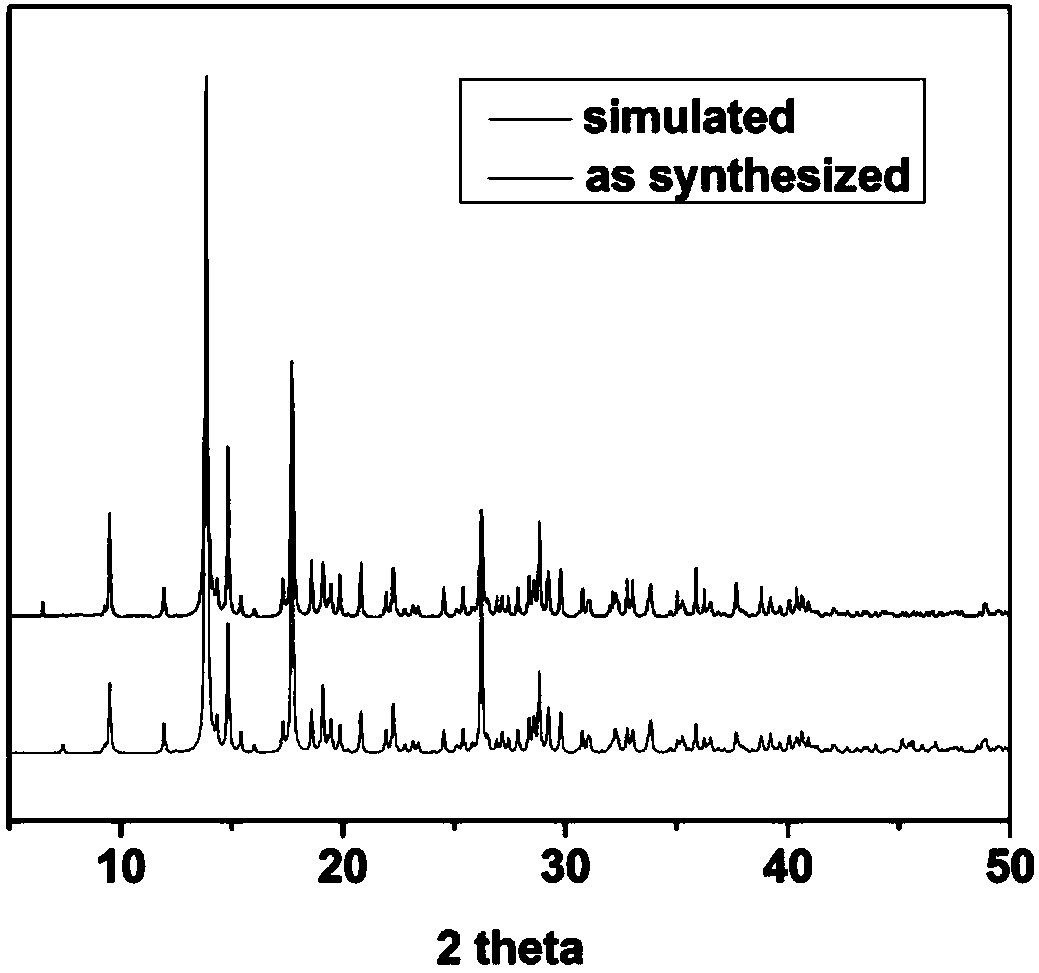

Preparation method for lithium battery anode material by taking metal organic frame as template

InactiveCN105932285AImprove electrochemical performanceAdjustable structureCell electrodesFinal product manufacturePhysical chemistryRoom temperature

The invention discloses a preparation method for a lithium battery anode material by taking a metal organic frame as a template. The preparation method of the lithium battery anode material comprises the steps of 1, synthesizing organic ligand 4, 4 Hopybz; 2, synthesizing a Pb-MOF material, weighing Pb(NO3)2 and the ligand 4, 4 Hopybz, dissolving the Pb(NO3)2 and the ligand 4, 4 Hopybz into solvent, carrying out heating and reacting in a reactor and cooling to a room temperature after reaction, thereby obtaining the Pb-MOF material; 3, preparing the lithium battery anode material, and heating to activate the Pb-MOF obtained in the step 2, thereby obtaining the lithium battery anode material. Compared with the prior art, the method has the advantages that a porous metal organic frame complex is synthesized, the complex is further activated, the complex is directly applied to a lithium battery as the anode material of the lithium battery, the structure and specific surface area of the metal organic frame are adjustable, and the prepared lithium battery anode material has good electrochemical performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Bacterial cellulose membrane/porous carbon adsorbent and preparation thereof

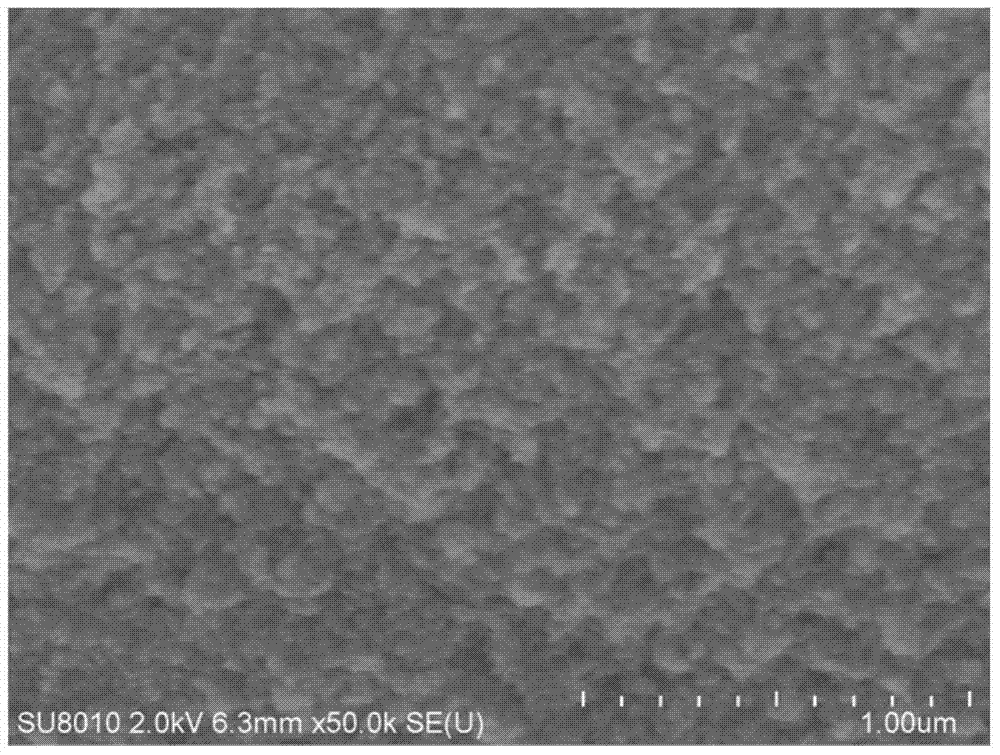

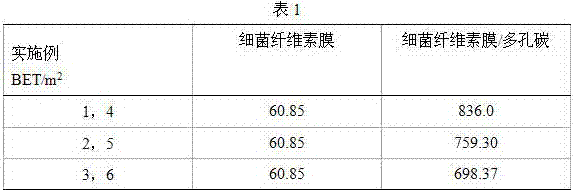

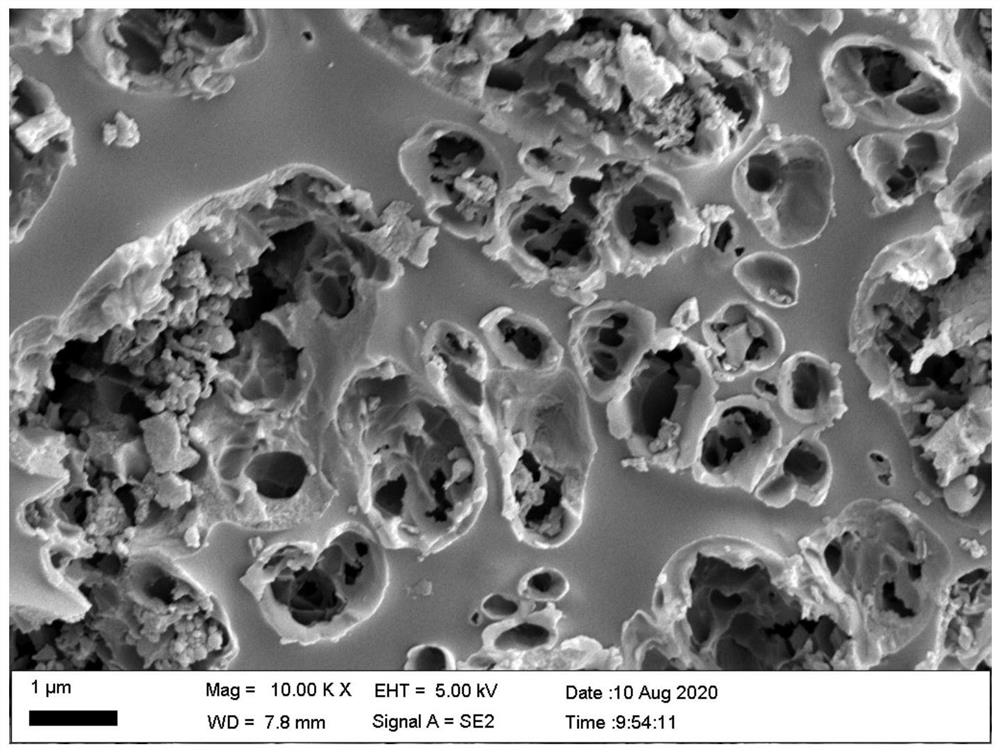

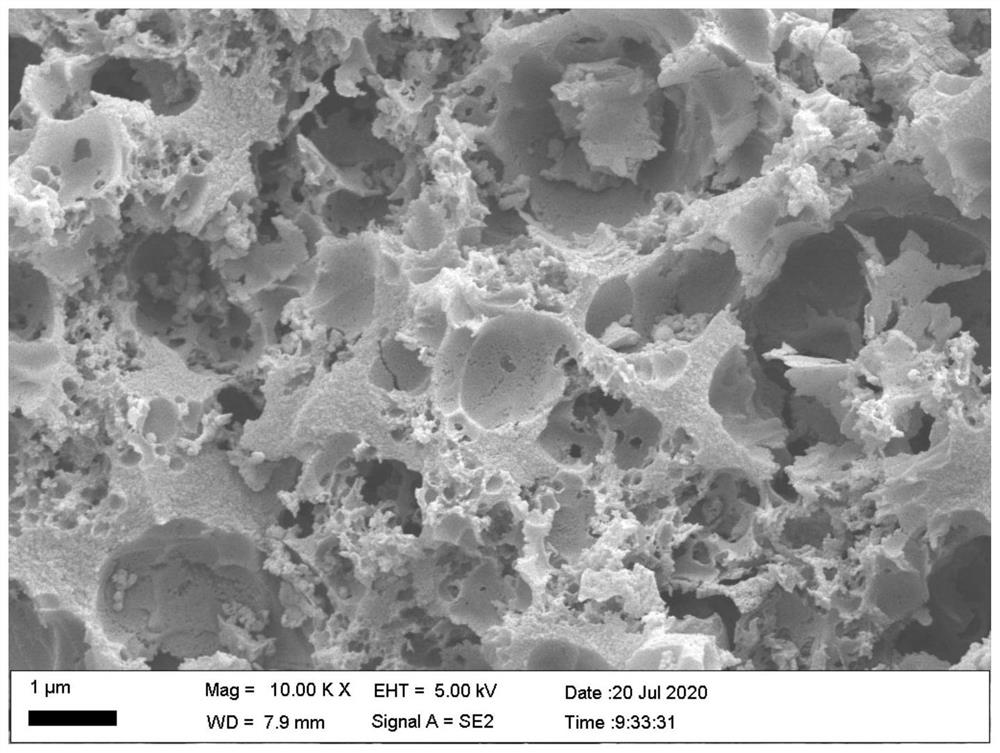

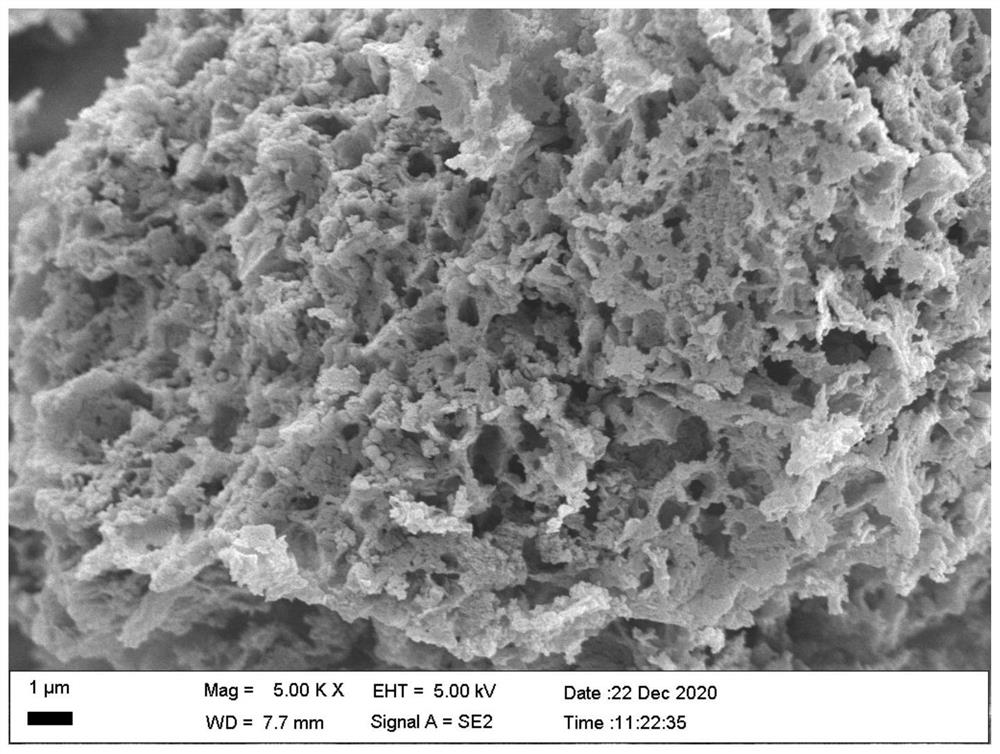

InactiveCN104722285AAperture adjustable sizeEvenly dispersedDispersed particle filtrationOther chemical processesToxic gasPorous carbon

The invention discloses a bacterial cellulose membrane / porous carbon adsorbent and preparation thereof. The bacterial cellulose membrane / porous carbon adsorbent is prepared by taking a bacterial cellulose membrane as a matrix, taking different saccharides as carbon sources and using a hydrothermal carbonization method; due to the anchoring function of a large number of hydroxyls on the surface of the bacterial cellulose, the porous carbon can be preferably dispersed in the bacterial cellulose membrane and different nano pore diameters can be obtained by adjusting the growth process of the bacterial cellulose membrane. The adsorbent combines the filtration of the nano pore diameters of the membrane and the adsorption of the porous carbon, is used for adsorbing and dispelling PM2.5 smoke and poisonous gas and has the advantages f being environmentally friendly and high in efficiency.

Owner:NANJING UNIV OF SCI & TECH +1

Preparation method of calcium hydroxide with high specific surface area for dry desulfurization

InactiveCN101774620BAdjustable specific surface areaHigh porosityDispersed particle separationCalcium hydroxidePolyol

The invention discloses a method for preparing calcium hydroxide with high specific surface area for dry desulfurization, which comprises the following steps: 1) Calcining limestone and anthracite to produce calcium oxide; , water reacts with calcium oxide in a spray state; 3) calcium hydroxide passes through a vibrating screen, and the gained calcium hydroxide enters a finished product storage bin; 4) sampling, and measuring the specific surface area of the calcium hydroxide finished product on a nitrogen adsorption specific surface meter; The digested water adopted in step 2) contains organic amine or / and polyhydric alcohol / inorganic sodium salt below 2.0%; the specific surface area of the calcium hydroxide manufactured by the method of the present invention is adjustable, and the prepared specific surface area reaches 15-30m2 / g Calcium hydroxide, according to the composition of the flue gas, provides calcium hydroxide with different specific surface areas to meet the requirements of desulfurization and reduce production costs.

Owner:CHANGSHU DAZHONG CALCIFIC OBJECTS

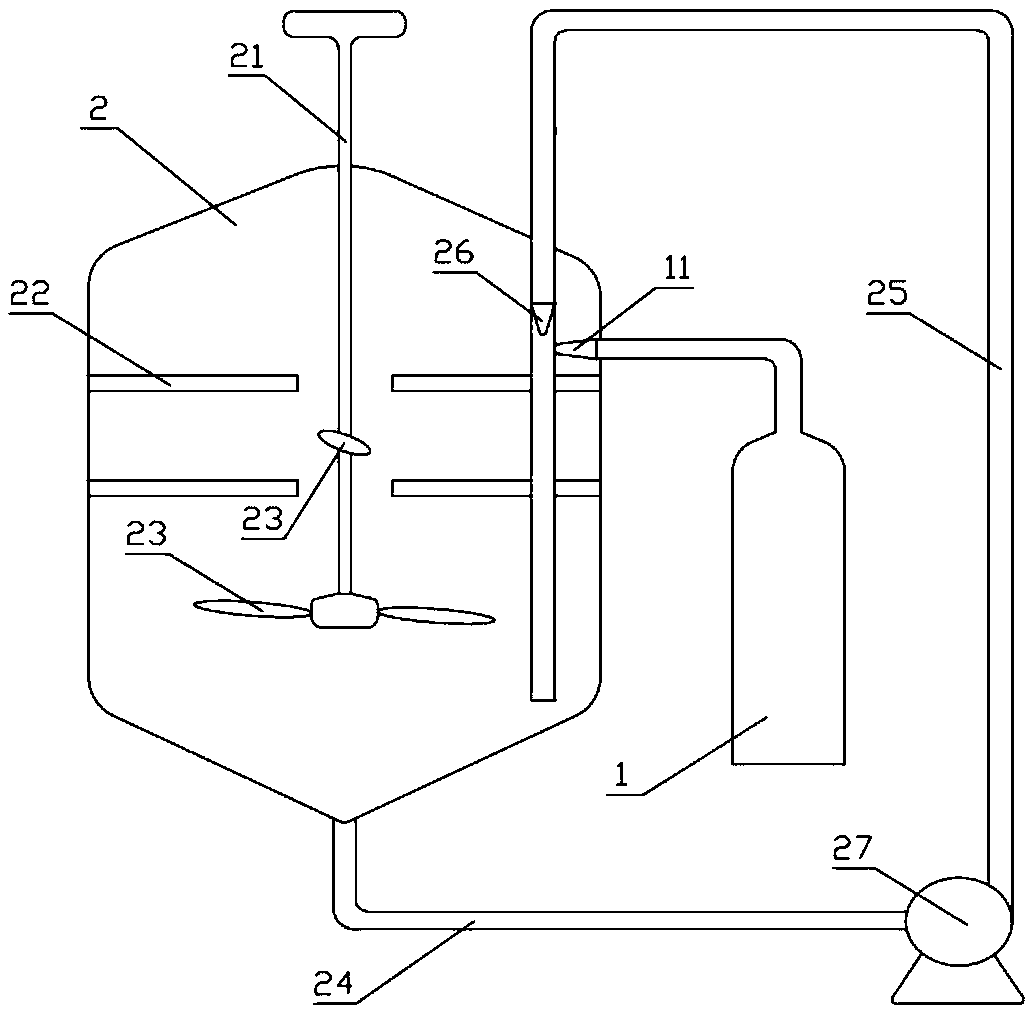

White carbon black and preparation method and application thereof

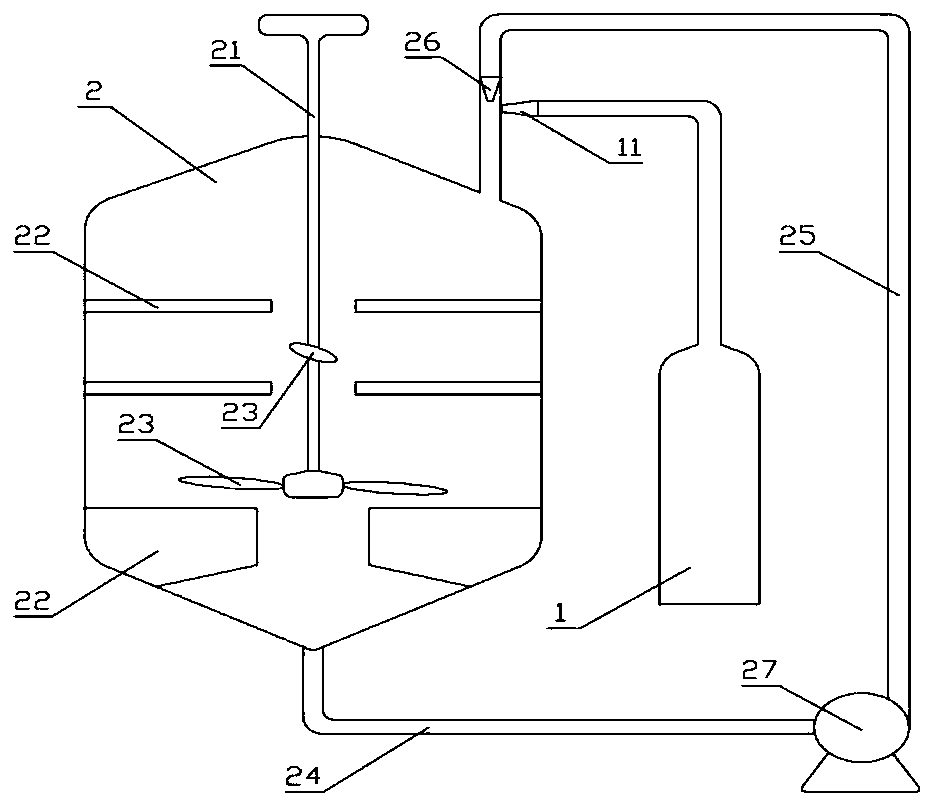

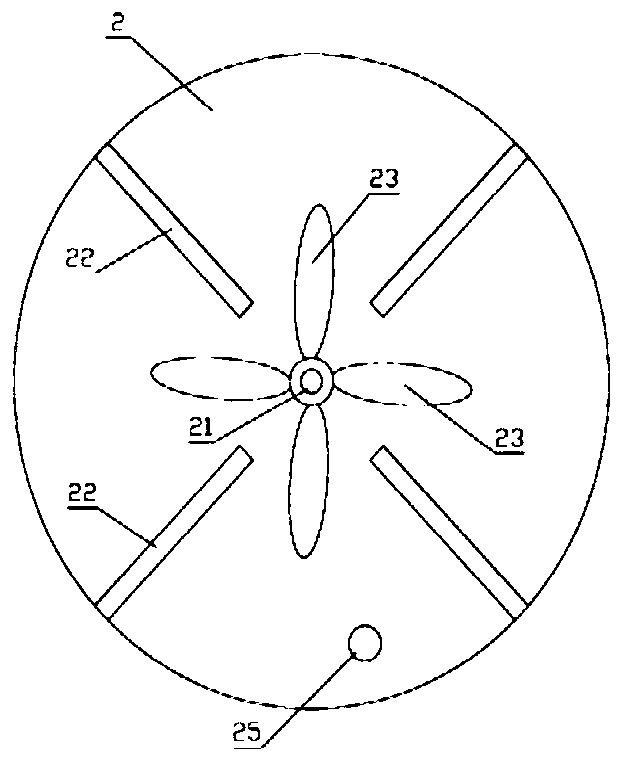

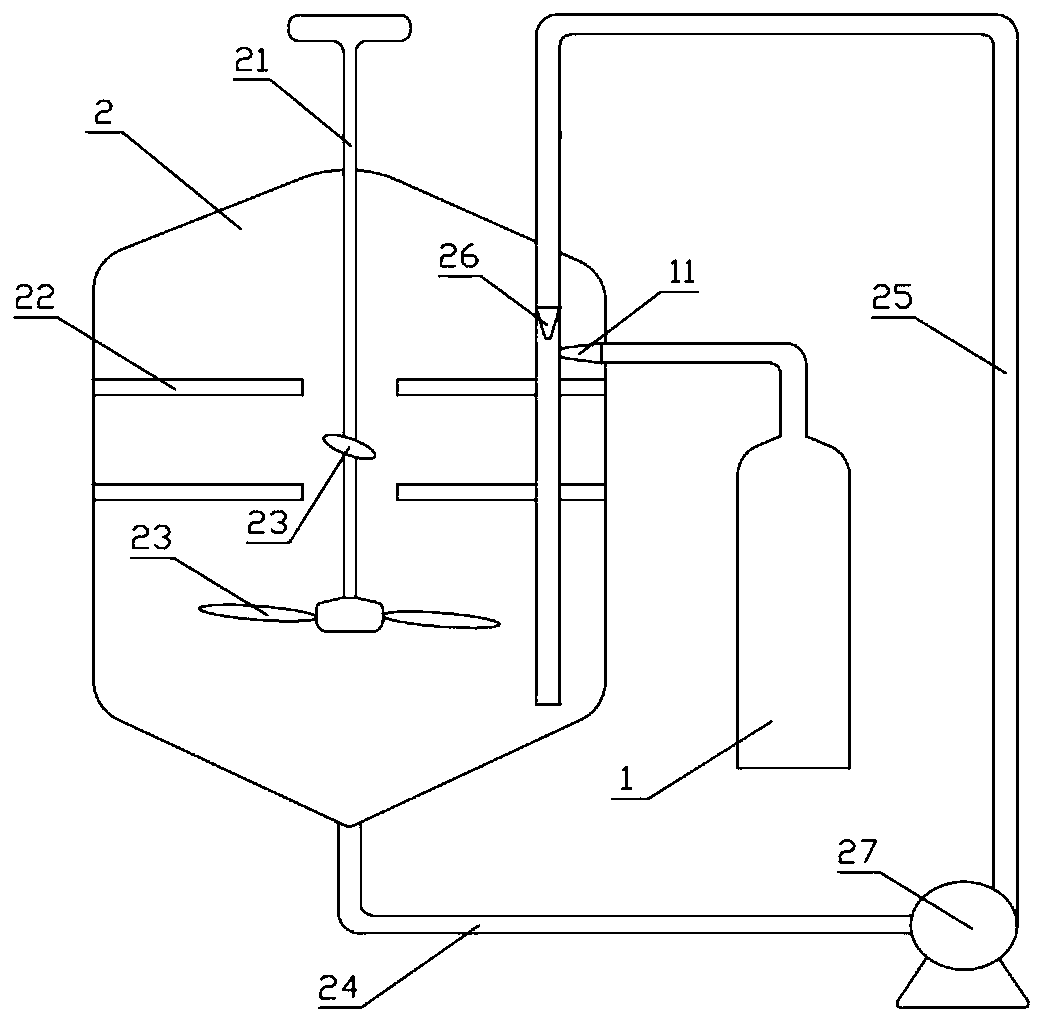

The invention belongs to the field of white carbon black preparation, and particularly relates to white carbon black and a preparation method and application thereof. The preparation method is capableof using a tail gas of carbon black production and the like as an acidifying agent, performing a precipitation reaction by using a stirring-auxiliary circulating-jet carbonization technology, and combining the advantages of three types of technologies of stirring, spraying and bubbling. The cost is cheap, the precipitation reaction efficiency is remarkably accelerated, and a precipitation white carbon black product of which the specific surface area is controllable can be efficiently synthesized. The preparation method is a recycling production system which is cheap in cost and green in design and manufacture, and has great industrial application value and potential social and economic benefits in the preparation industry of a tire rubber reinforcing agent.

Owner:EVE RUBBER RES INST

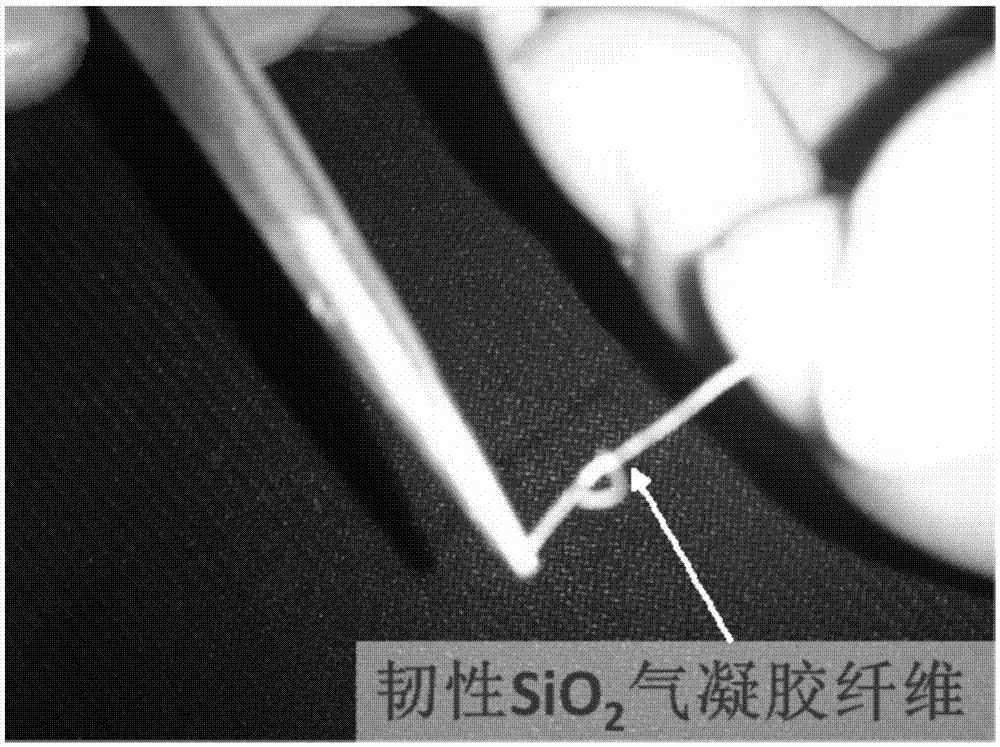

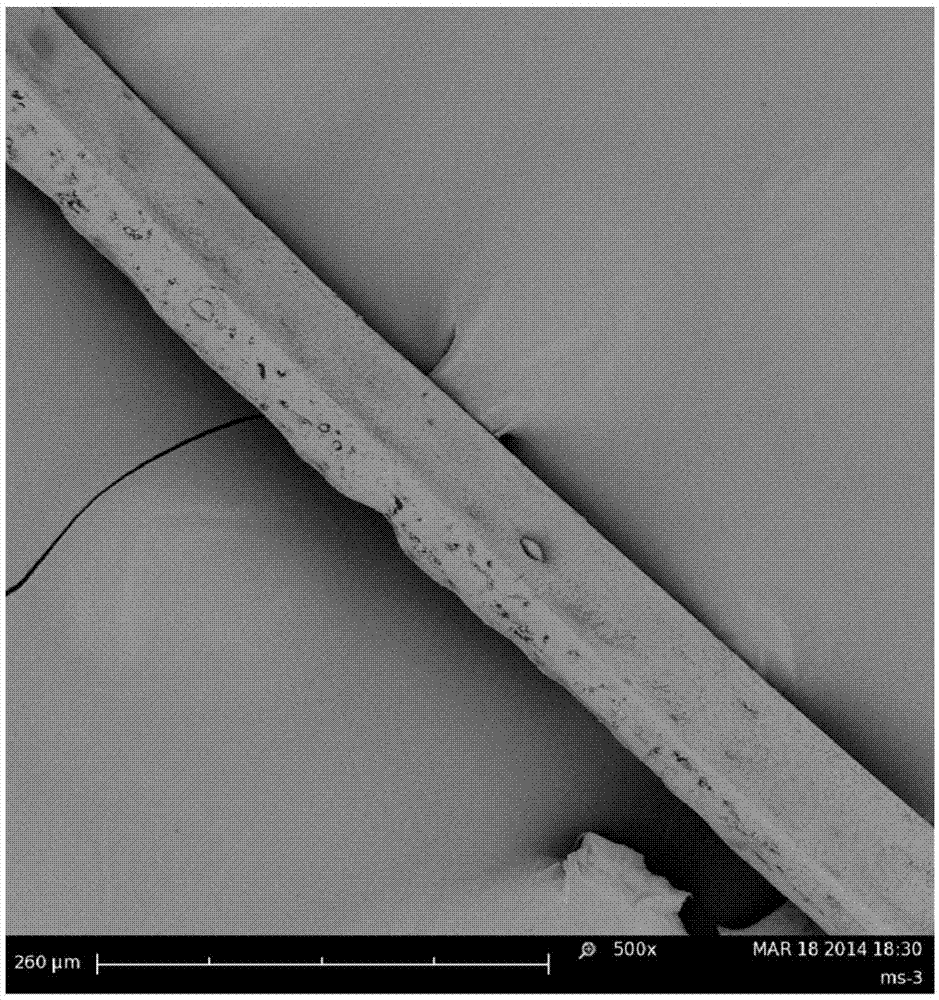

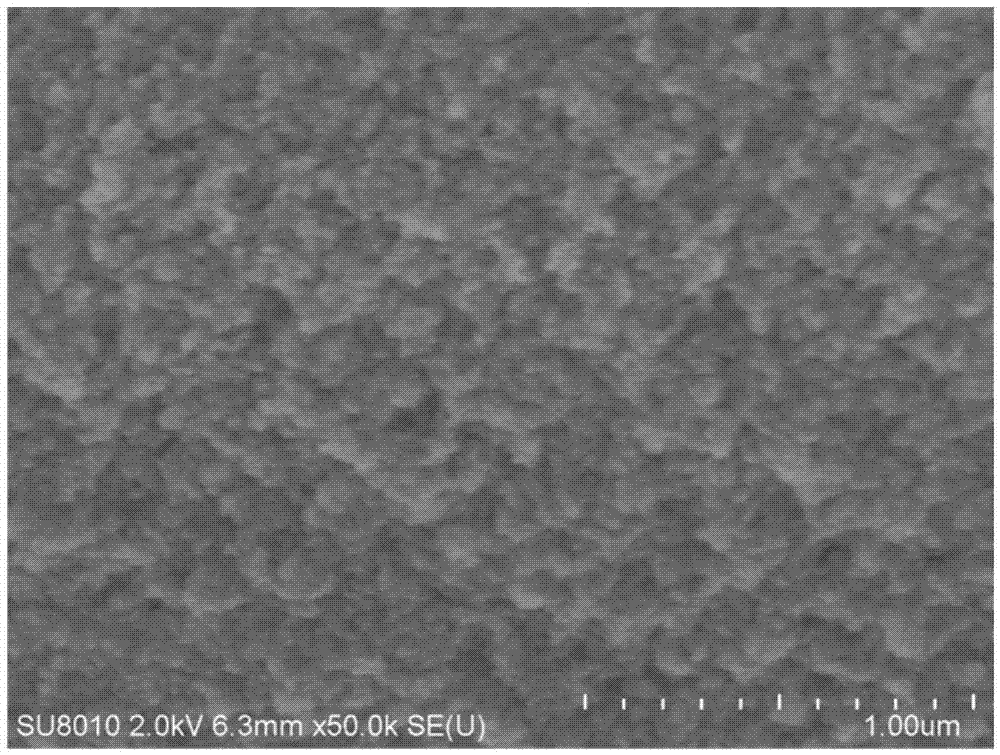

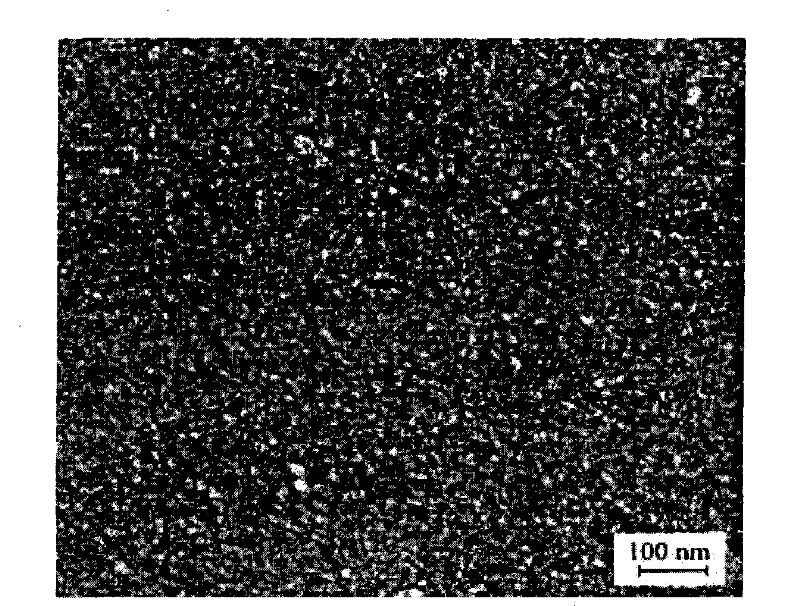

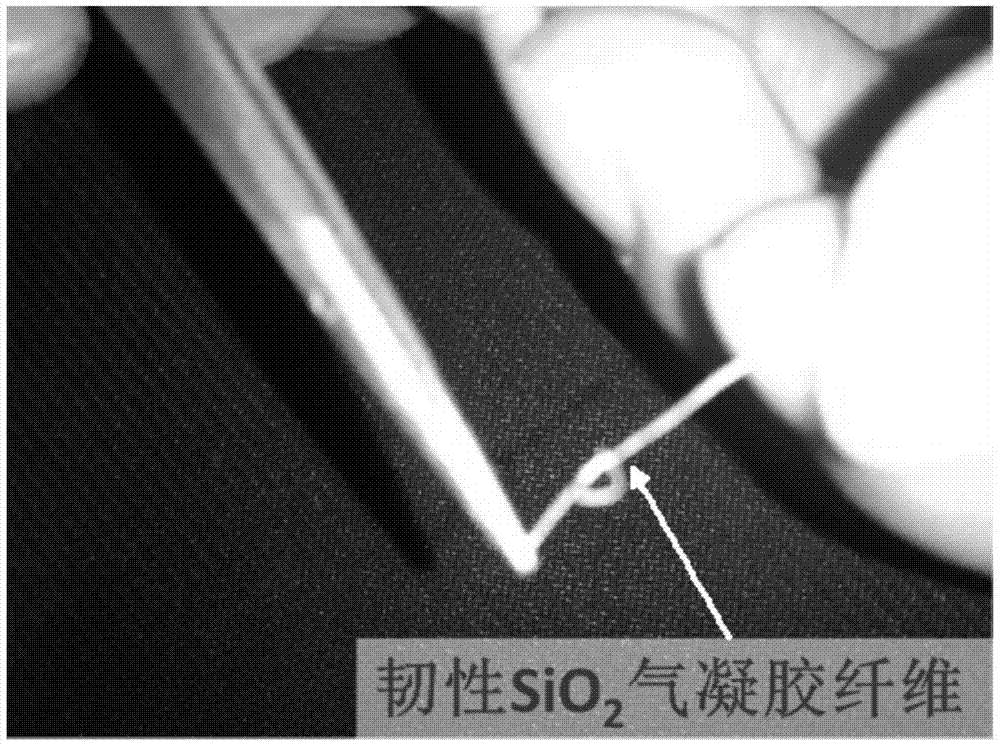

Preparation method of ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone)

ActiveCN105442098AImprove toughnessToughness hasInorganic material artificial filamentsWet spinning methodsFiberPolymer science

The invention relates to a preparation method of a ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone). The preparation method comprises the following steps: a spinning solution is prepared from silicate or silanol sol; an acid solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution is added to the coagulating bath for reaction wet spinning, an orthosilicic acid / silicate fiber is obtained and is subjected to winding, aging and washing to be neutral, and solvent exchange and drying performed; the dried fiber is soaked in a PVP aqueous solution, taken out and dried, and a product is obtained. The preparation method has the characteristics of cheap and available raw materials, simple reaction process and good spinnability; the prepared inorganic SiO2 aerogel fiber has rich pores, high specific surface area, high-temperature resistance and chemical corrosion resistance, meanwhile, the specific surface area of the fiber is adjustable, the fiber has certain toughness, the application range of the aerogel fiber can be expanded, and the aerogel fiber has higher practical value.

Owner:DONGHUA UNIV

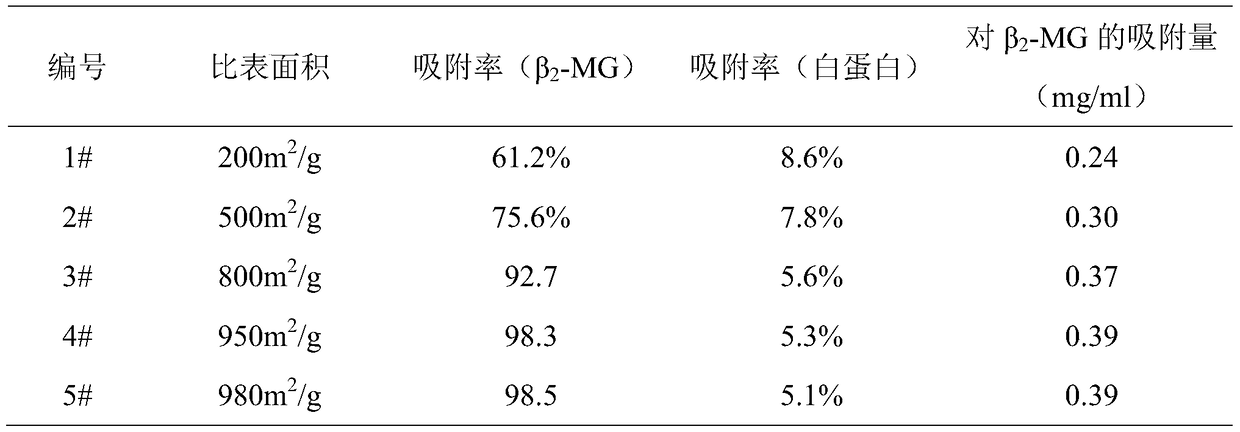

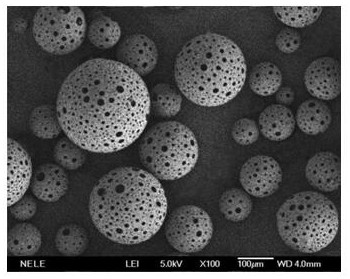

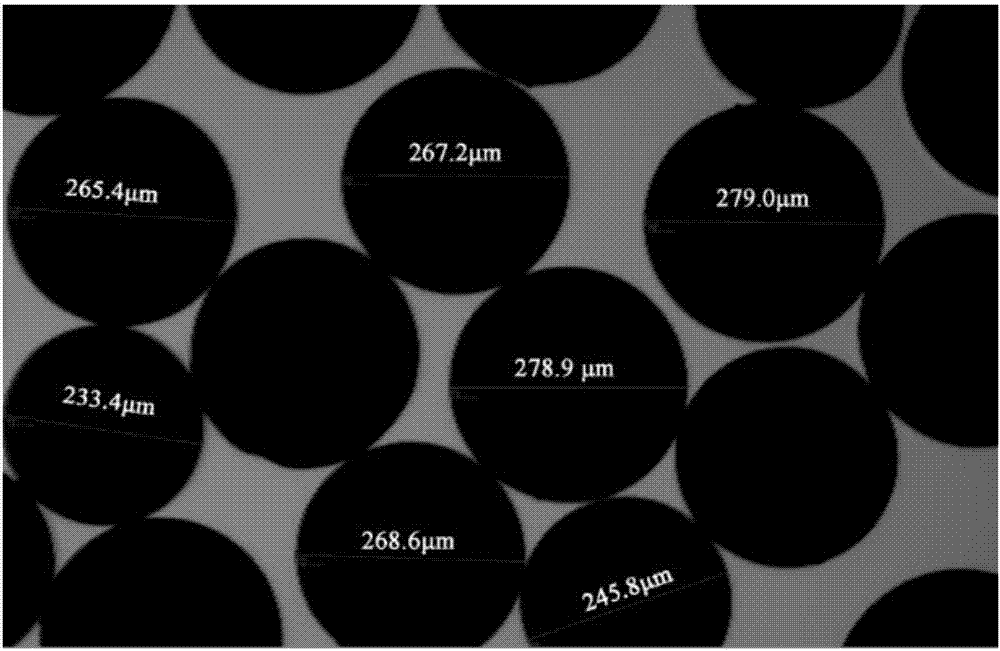

Preparation method of resin used for blood purification to remove β2-microglobulin

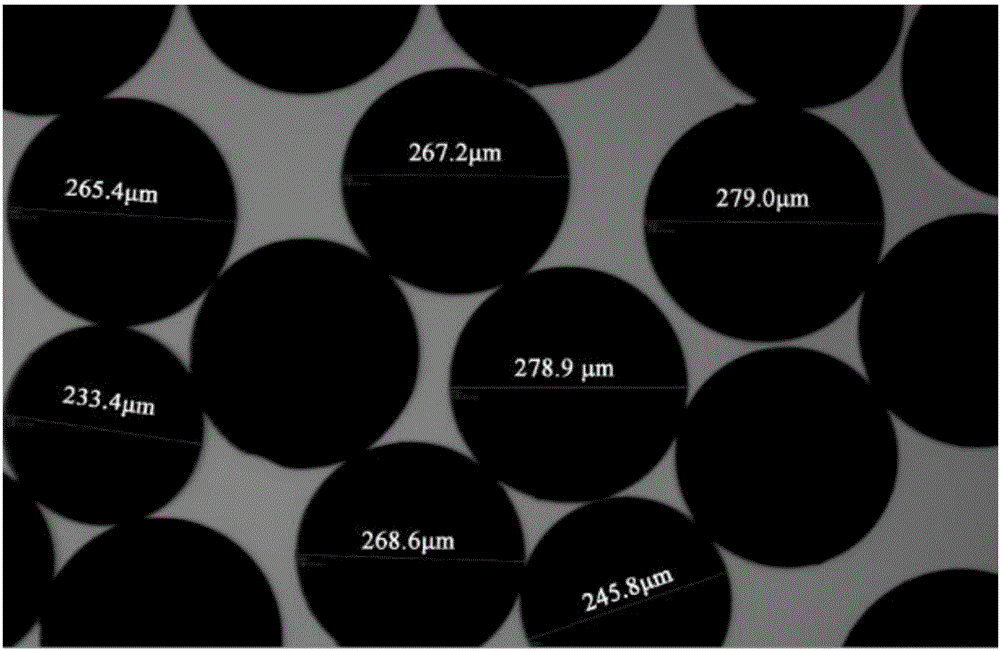

ActiveCN105504131BFlat surfaceHigh strengthMicroballoon preparationMicrocapsule preparationDivinylbenzeneMicrosphere

The invention discloses a preparing method for resin for clearing away beta2-microglobulin in blood purification. The preparing method comprises the steps that firstly, polystyrene-divinylbenzene microspheres are prepared; secondly, the polystyrene-divinylbenzene microspheres and chloromethyl ether are subjected to a chloromethylation reaction, and chloromethylation microspheres are obtained; finally, long-chain hydrophobic groups are grafted to the chloromethylation microspheres. By means of the preparing method, styrene and divinybenzene serve as monomers, the polystyrene-divinylbenzene microspheres are obtained through suspension polymerization, and the size of pores in the microspheres is adjusted with a certain quantity of a pore-forming agent in the synthesizing process; then the microspheres serve as a carrier, alkyl is grafted through the chloromethylation reaction and an amination reaction, the microspheres with the adjustable specific surface area and the hydrophobic groups are obtained, and the resin is smooth in surface and high in strength and has very high adsorption performance on beta2-microglobulin in a uremia patient. The production technology is simple, the yield is high, and the product purity is high; meanwhile, raw materials are easy to obtain, and mass production and preparation can be achieved.

Owner:重庆希尔康血液净化器材研发有限公司

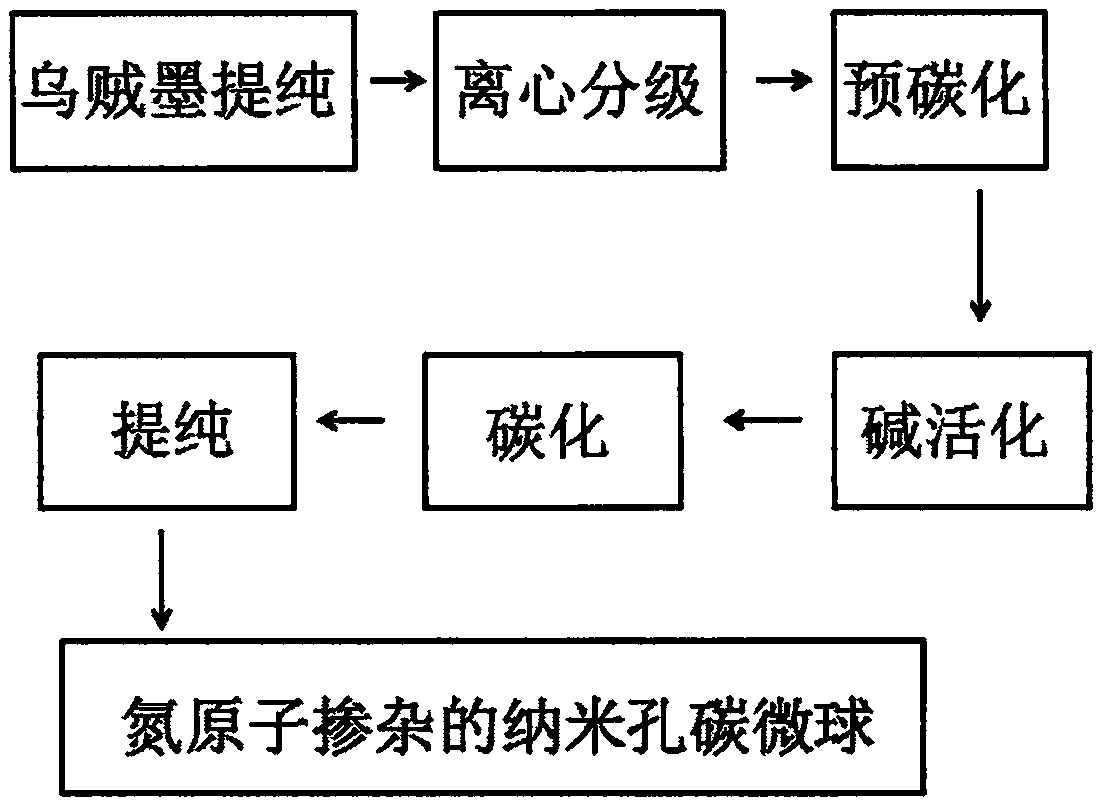

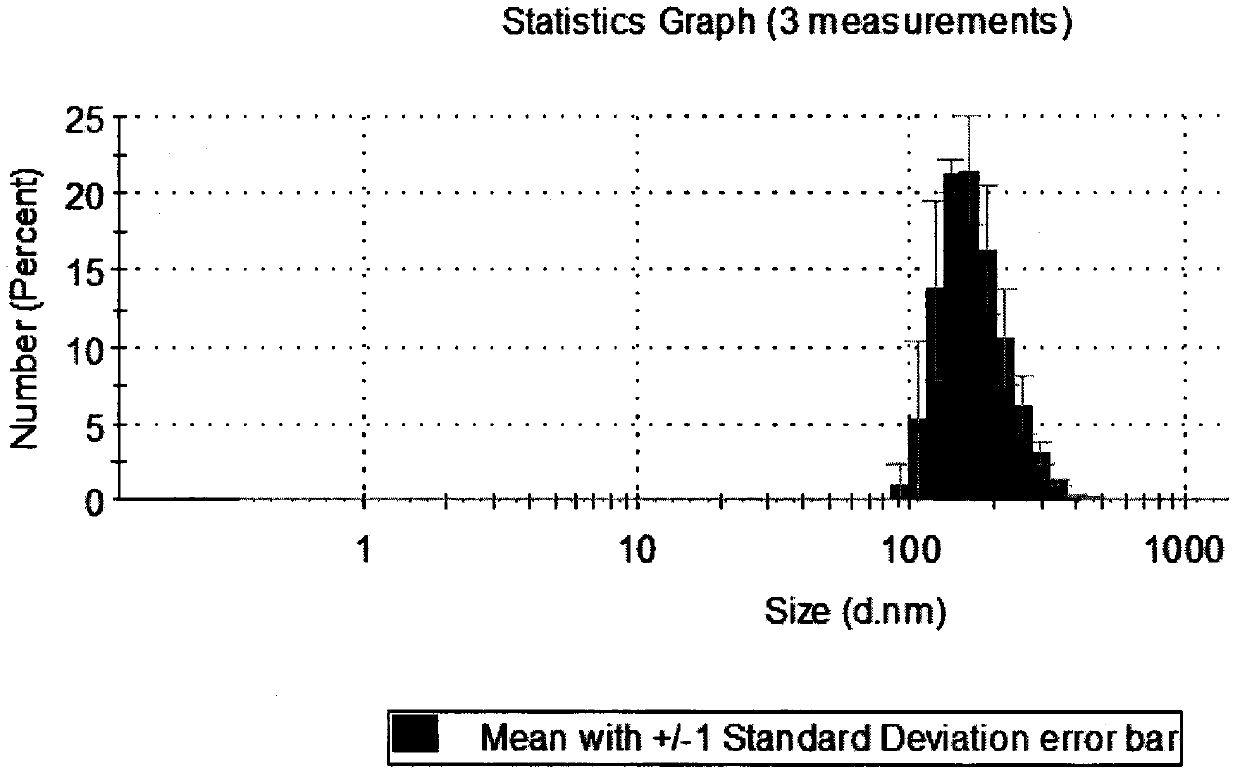

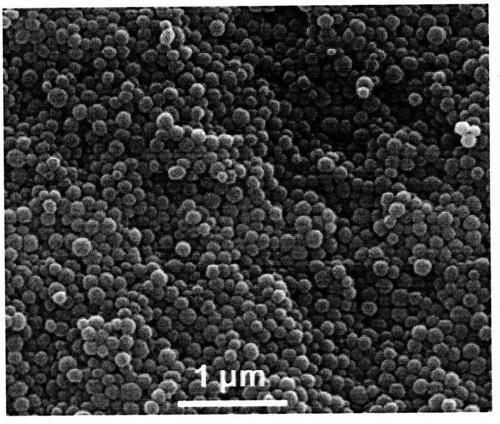

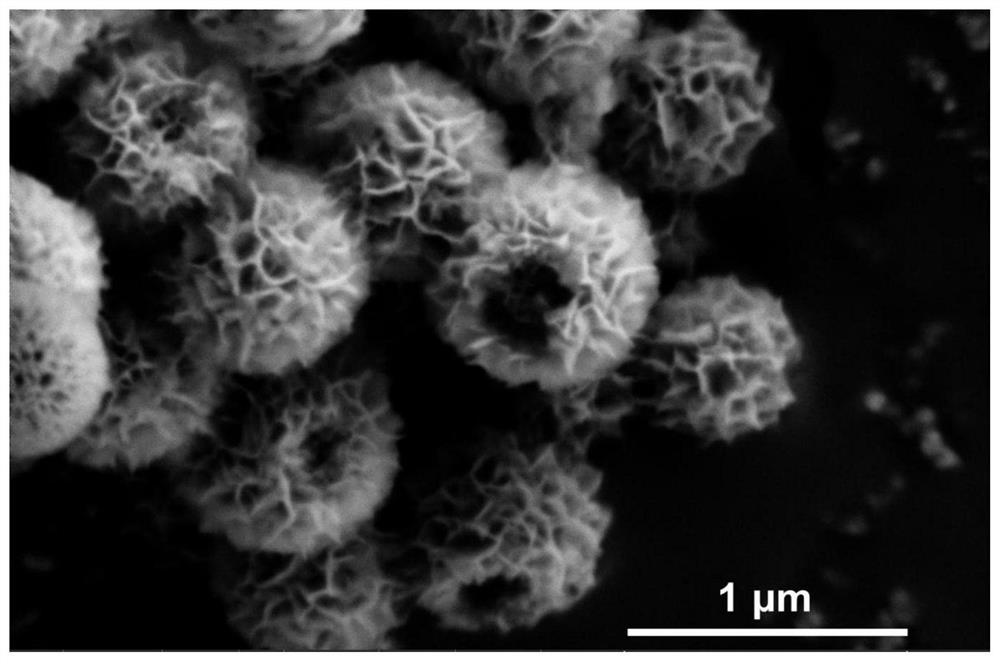

Method for preparing nitrogen-doped nanoporous carbon microspheres by using sepia as raw material

InactiveCN110092377ARich in mesoporesImprove conductivityMaterial nanotechnologyCarbon compoundsMicrosphereFiltration

The invention discloses a method for preparing nitrogen-doped nanoporous carbon microspheres by using sepia as a raw material. The method comprises: A, taking live squid, taking out ink sac, extrudingink, carrying out centrifuging grading, and taking the black pigment of the precipitate; B, pre-carbonizing the precipitate obtained in the step A, and naturally cooling; C, placing the pre-carbonized product obtained in the step B in a potassium hydroxide aqueous solution, and completely activating; D, carbonizing the activated product obtained in the step C again, and naturally cooling; E, soaking in a hydrochloric acid solution; and F, carrying out suction filtration cleaning with pure water, and drying to obtain the monodisperse nitrogen atom-doped nanoporous carbon microspheres. According to the present invention, the method can improve the deficiencies in the prior art, and is simple, and the product has high performance price ratio.

Owner:EAST CHINA UNIV OF TECH

Submillimeter-level polystyrene-base spherical active carbon, and preparation method and application thereof

ActiveCN106219543AReduce manufacturing costSave raw materialsOther chemical processesAlkali metal oxides/hydroxidesMicrosphereDivinylbenzene

The invention discloses a submillimeter-level polystyrene-base spherical active carbon, and a preparation method and application thereof. The preparation method comprises the following steps: preparing polystyrene-base microspheres from styrene and divinylbenzene, swelling the polystyrene-base microspheres in carbon tetrachloride, adding a catalyst, and curing to form to obtain the super-crosslinked thermosetting polystyrene-base resin spheres; immersing the resin spheres in a saturated sodium chloride solution, cleaning sequentially with dilute hydrochloric acid, a sodium hydroxide solution and deionized water to a neutral state, and drying; carrying out high temperature carbonization and vapor activation to obtain polystyrene-base spherical active carbon; and carrying out surface modification on the polystyrene-base spherical active carbon by air oxidation and high-temperature nitrogen heat treatment. The preparation method is simple in technique, and lowers the production cost. The obtained spherical active carbon has the advantages of smooth surface, high sphericity and large specific area (up to 960-1400 m<2> / g), can be used for adsorbing urotoxin creatinine, and has wide application prospects in the field of uremia treatment.

Owner:CHANGZHOU YINGZHONG NANO TECH

A kind of preparation method of continuous sio2 airgel fiber

ActiveCN105671687BAdjust the size of the specific surface areaInnovativeInorganic material artificial filamentsWet spinning methodsFiberSilicic acid

Owner:DONGHUA UNIV

A kind of white carbon black and its preparation method and application

The invention belongs to the field of white carbon black preparation, and particularly relates to white carbon black and a preparation method and application thereof. The preparation method is capableof using a tail gas of carbon black production and the like as an acidifying agent, performing a precipitation reaction by using a stirring-auxiliary circulating-jet carbonization technology, and combining the advantages of three types of technologies of stirring, spraying and bubbling. The cost is cheap, the precipitation reaction efficiency is remarkably accelerated, and a precipitation white carbon black product of which the specific surface area is controllable can be efficiently synthesized. The preparation method is a recycling production system which is cheap in cost and green in design and manufacture, and has great industrial application value and potential social and economic benefits in the preparation industry of a tire rubber reinforcing agent.

Owner:EVE RUBBER RES INST

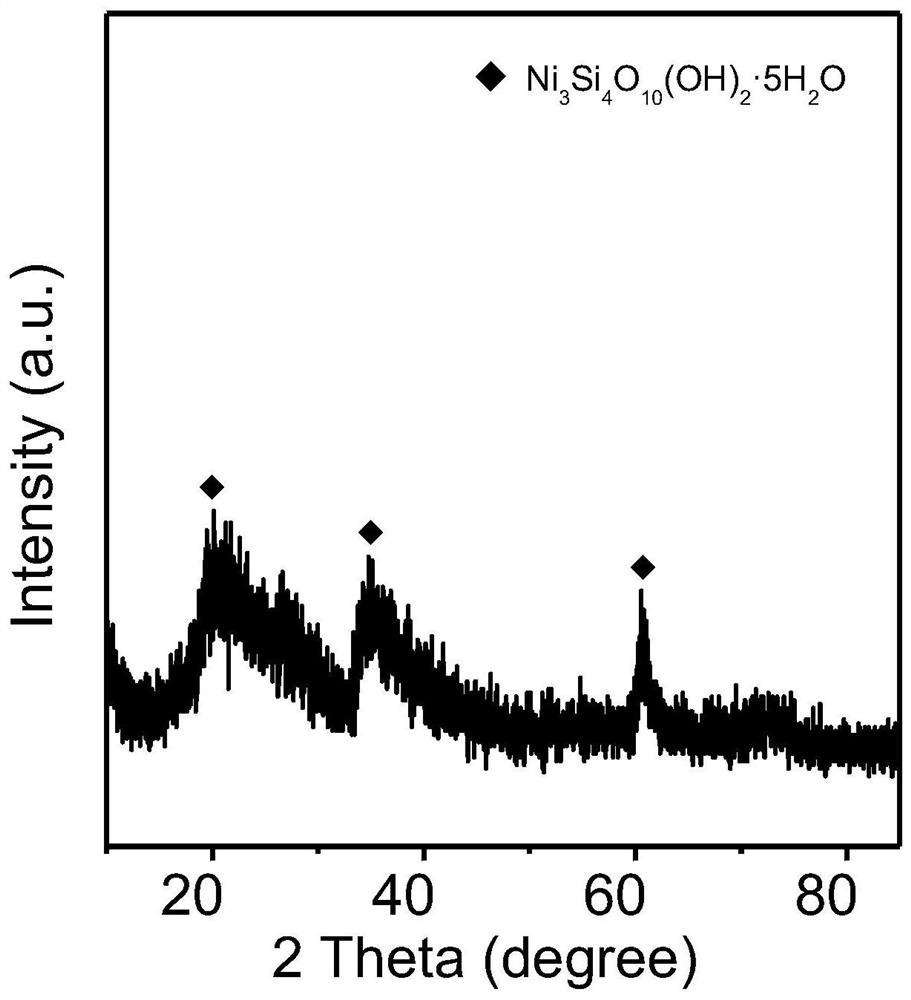

Method for preparing basic nickel silicate catalyst from silicon-containing industrial solid waste

PendingCN111841548ALow costSimplify the complexityGaseous fuelsCatalyst activation/preparationPtru catalystSilicic acid

Owner:SHANDONG UNIV OF SCI & TECH

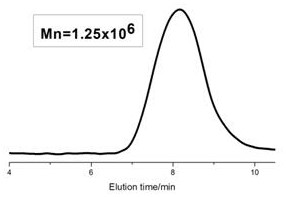

Porous ultra-high molecular weight poly fluorine-containing olefin hollow microspheres and preparation method thereof

The preparation method comprises the following steps: (1) vacuumizing a reaction kettle, introducing nitrogen, and adding a metal nano catalyst and reactants according to a certain mass ratio; (2) heating the reaction kettle to 30-60 DEG C, stirring at the rotating speed of 500-1500 r / min, and adding a pore-foaming agent; (3) maintaining the rotating speed at 500-1500 r / min, and filling a fluorine-containing monomer to reach the polymerization reaction pressure; and (4) centrifuging, washing and drying the polymerization product. The molecular weight of the obtained fluorine-containing olefin hollow microspheres is 1.5-3.0 times that of a polymer obtained through common free radical polymerization, the molecular weight distribution is narrow, the size of the microspheres is 10-200 m, and the pore diameter is 5-20 m. And the obtained product has high porosity and is applied to lithium battery binders, diaphragms and high-efficiency catalyst carriers. The method is mild in reaction condition, low in cost and environment-friendly, and has an excellent industrial prospect.

Owner:ZHEJIANG UNIV OF TECH

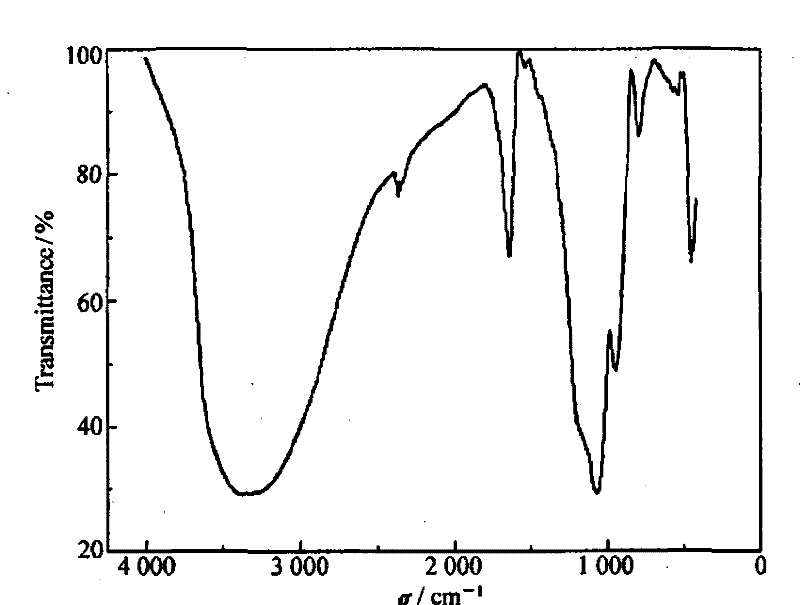

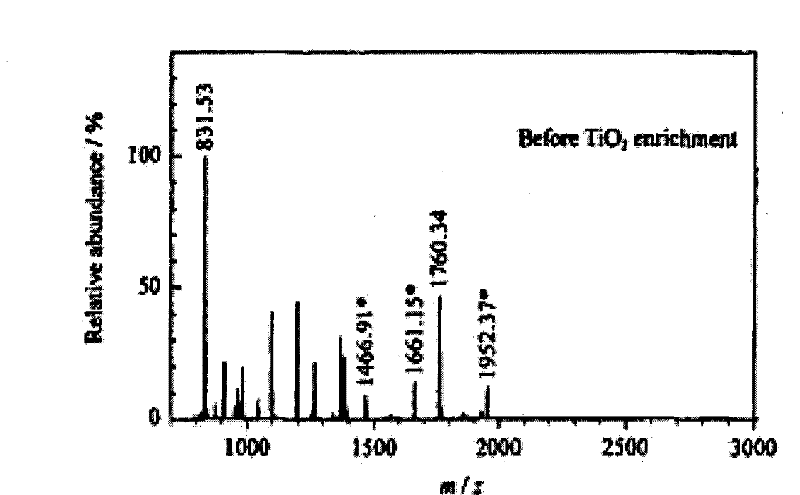

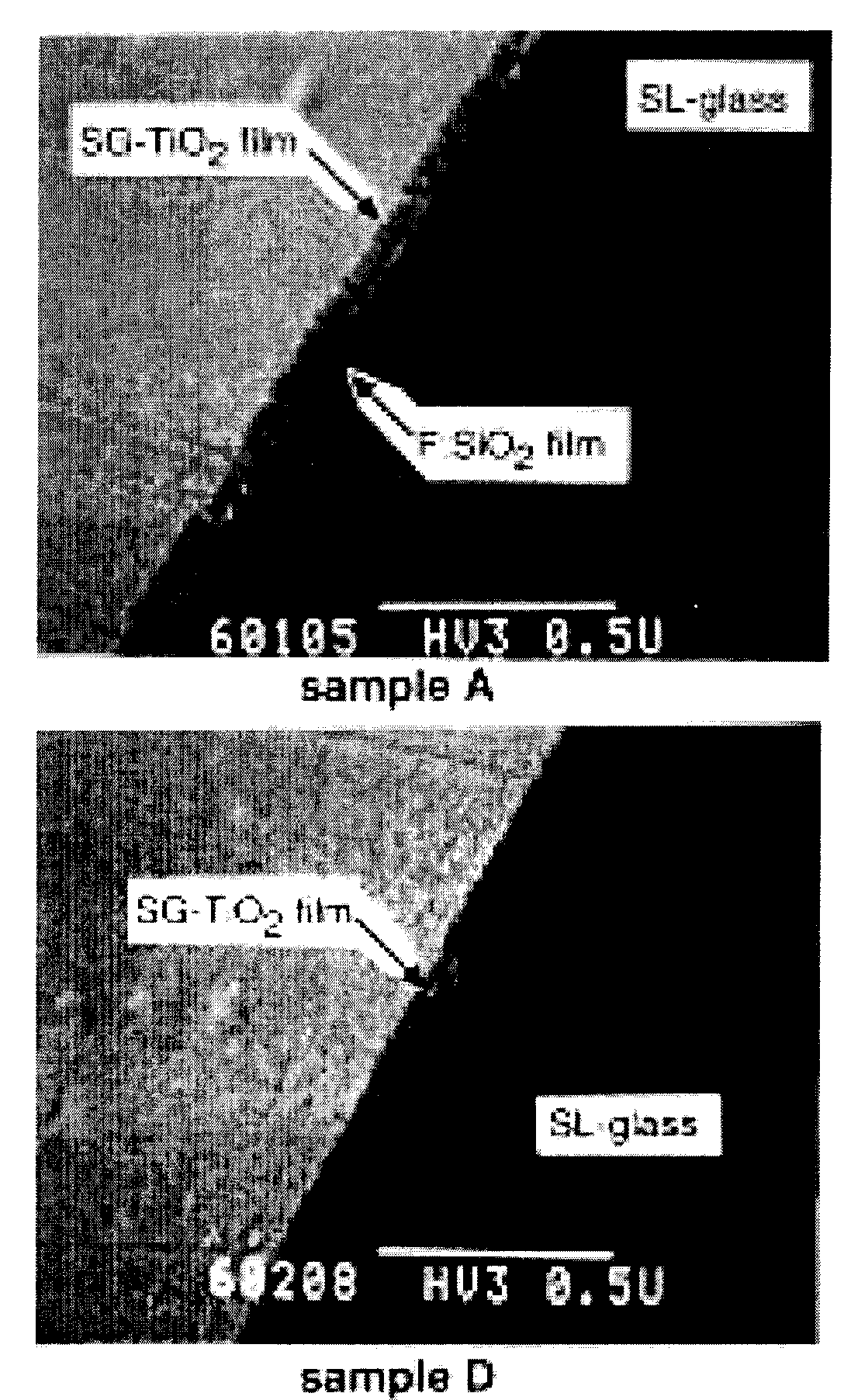

Method for producing capillary electrochromatography monolithic column made from silicon dioxide-titanic oxide integral material and uses thereof

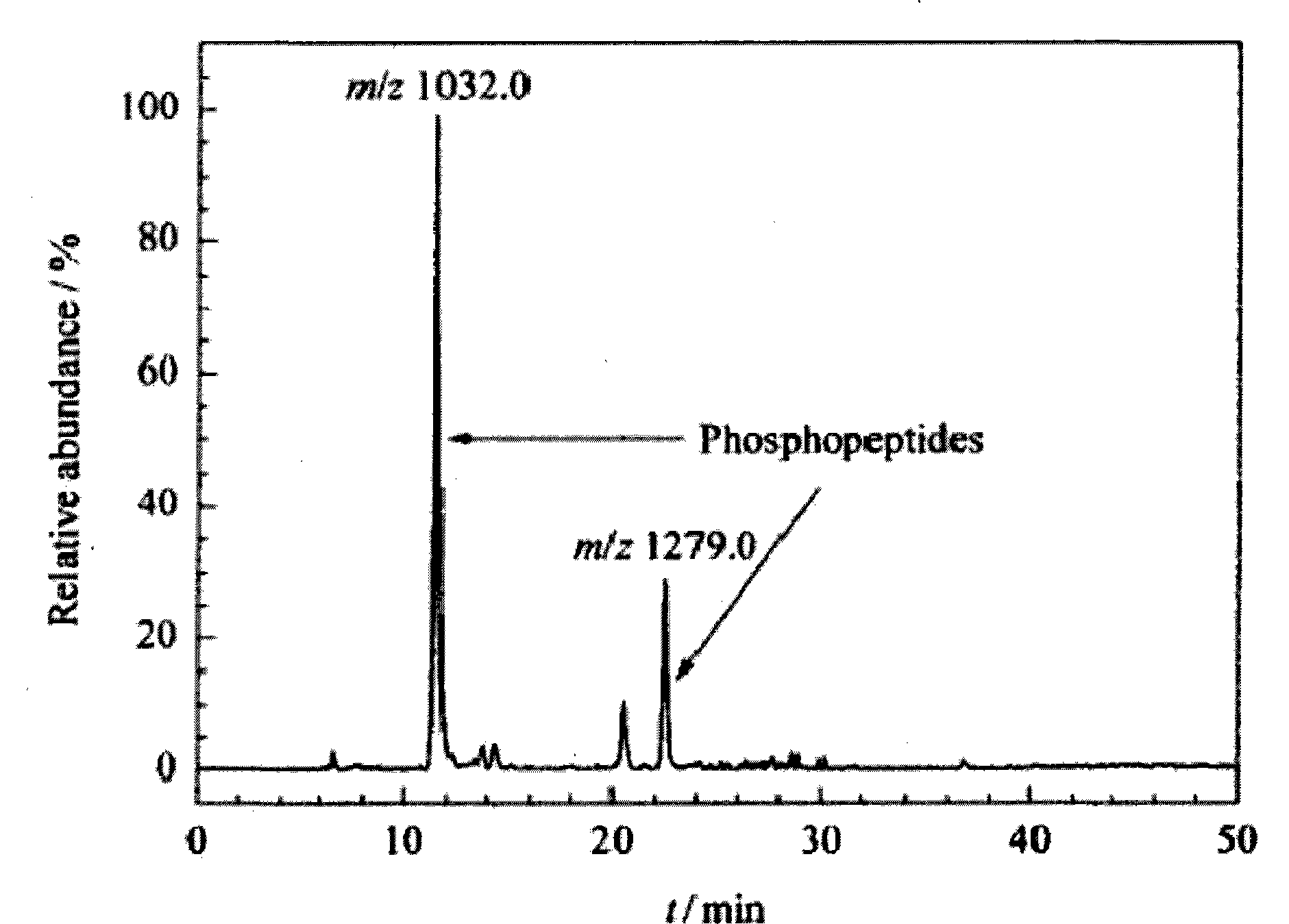

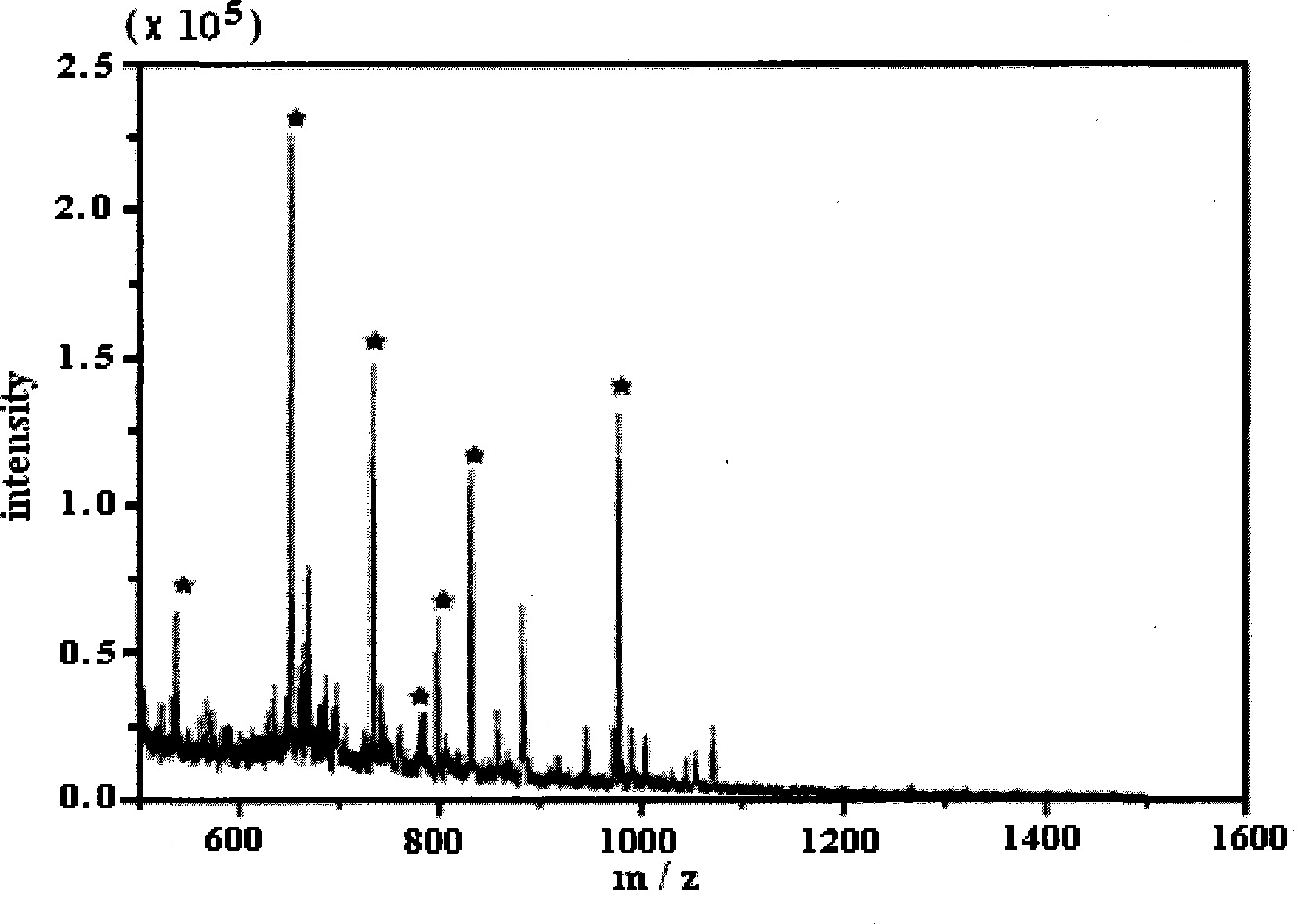

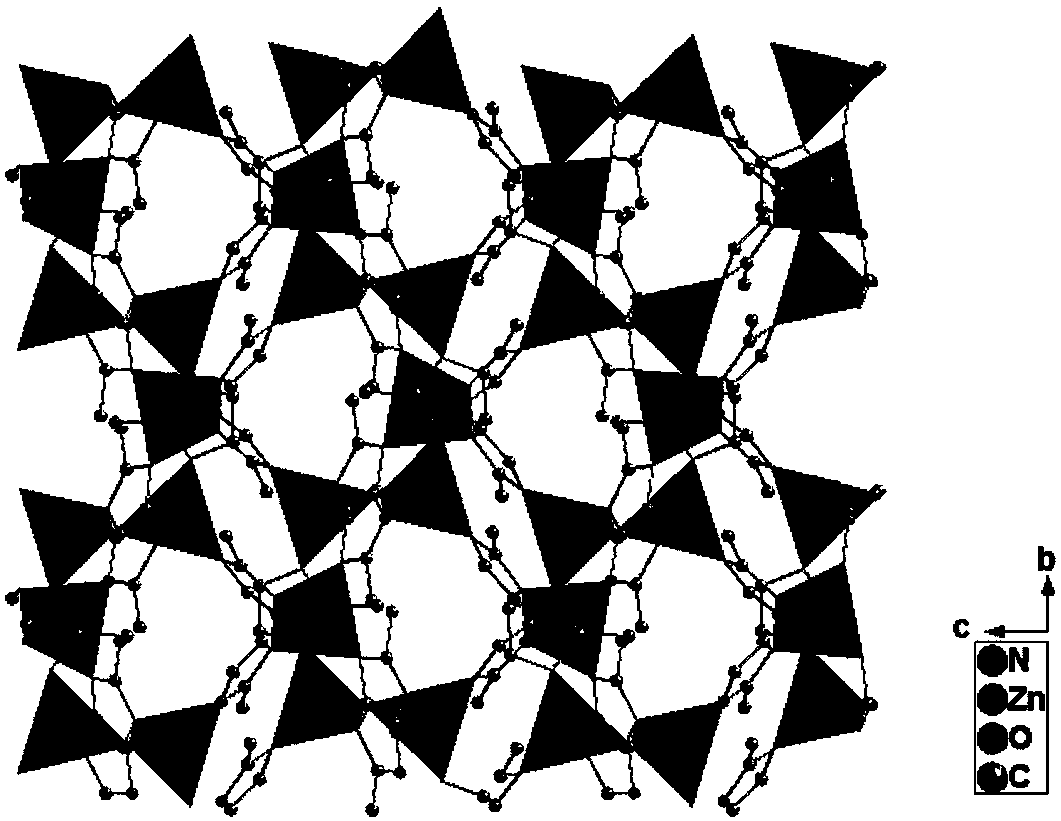

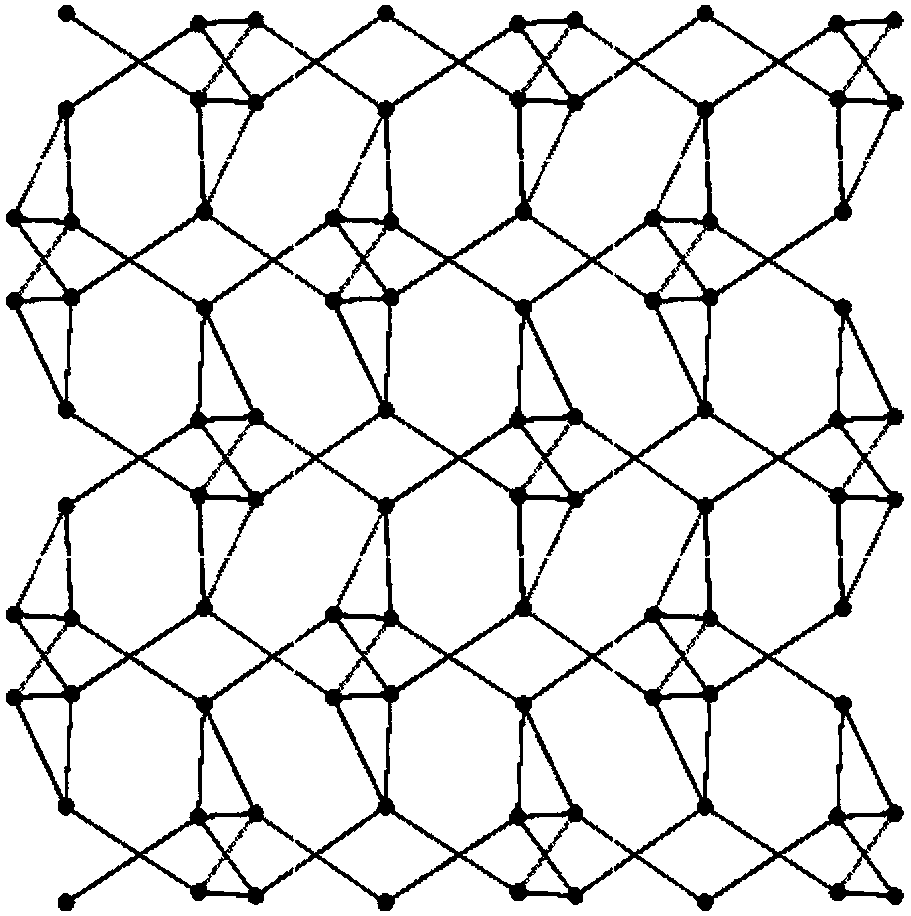

InactiveCN101406827BHigh mechanical strengthExtended service lifeComponent separationOther chemical processesElectrochromatographyPhosphorylation

The invention discloses a method for preparing an electrochromatography monolithic column of silicon dioxide-titanium dioxide monolithic materials, as well as application thereof. The titanium dioxide-silicon dioxide forms a mesopore molecular sieve under the action of a supramolecular template of which the mechanical strength is good, and pore diameter is easy to control according to requirement. A uniform capillary electrochromatography column with high specific surface area is prepared by one-step method. The method has the advantages that the mesopore molecular sieve which is prepared by using the supramolecular template as a structure-directing agent and has a specific pore structure, extremely high specific surface area and uniform adjustable pore diameter has the advantages of simple preparation method, good repeatability and high separation efficiency, and is suitable for the separation and enrichment of phosphorylated polypeptide, wherein titanium dioxide and silicon dioxide molecules are combined with silicon hydroxyl on the surface of the inner wall of a capillary through chemical bonds; a framework structure and the pore diameter of nanometer pores can be conveniently controlled by changing the categories and proportion of the supramolecular template; and surface properties and the chemical environment of a pore cavity are regulated so as to provide a specific molecular field.

Owner:EAST CHINA UNIV OF SCI & TECH

A pvp coated resilient sio 2 Preparation method of airgel fiber

ActiveCN105442098BImprove toughnessToughness hasInorganic material artificial filamentsWet spinning methodsFiberPolymer science

The invention relates to a preparation method of a ductile SiO2 aerogel fiber coated with PVP (polyvinylpyrrolidone). The preparation method comprises the following steps: a spinning solution is prepared from silicate or silanol sol; an acid solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution is added to the coagulating bath for reaction wet spinning, an orthosilicic acid / silicate fiber is obtained and is subjected to winding, aging and washing to be neutral, and solvent exchange and drying performed; the dried fiber is soaked in a PVP aqueous solution, taken out and dried, and a product is obtained. The preparation method has the characteristics of cheap and available raw materials, simple reaction process and good spinnability; the prepared inorganic SiO2 aerogel fiber has rich pores, high specific surface area, high-temperature resistance and chemical corrosion resistance, meanwhile, the specific surface area of the fiber is adjustable, the fiber has certain toughness, the application range of the aerogel fiber can be expanded, and the aerogel fiber has higher practical value.

Owner:DONGHUA UNIV

A bacterial cellulose membrane/porous carbon adsorbent and its preparation

InactiveCN104722285BAperture adjustable sizeEvenly dispersedDispersed particle filtrationOther chemical processesFiberPorous carbon

The invention discloses a bacterial cellulose membrane / porous carbon adsorbent and its preparation. The adsorbent uses bacterial cellulose membrane as a substrate, and different sugars as carbon sources. The bacterial cellulose membrane / porous carbon adsorbent is prepared by hydrothermal carbonization. Due to the anchoring effect of a large number of hydroxyl groups on the surface of bacterial cellulose, the porous carbon It can be better dispersed in the bacterial fiber membrane, and at the same time, different sizes of nanopores can be obtained by adjusting the growth process of the cellulose membrane. The adsorbent of the present invention combines the dual functions of membrane nano-pore filtration and porous carbon adsorption, and is used to adsorb and remove PM2.5 smoke dust and toxic gases. The adsorbent has the advantages of environmental protection and high efficiency.

Owner:NANJING UNIV OF SCI & TECH +1

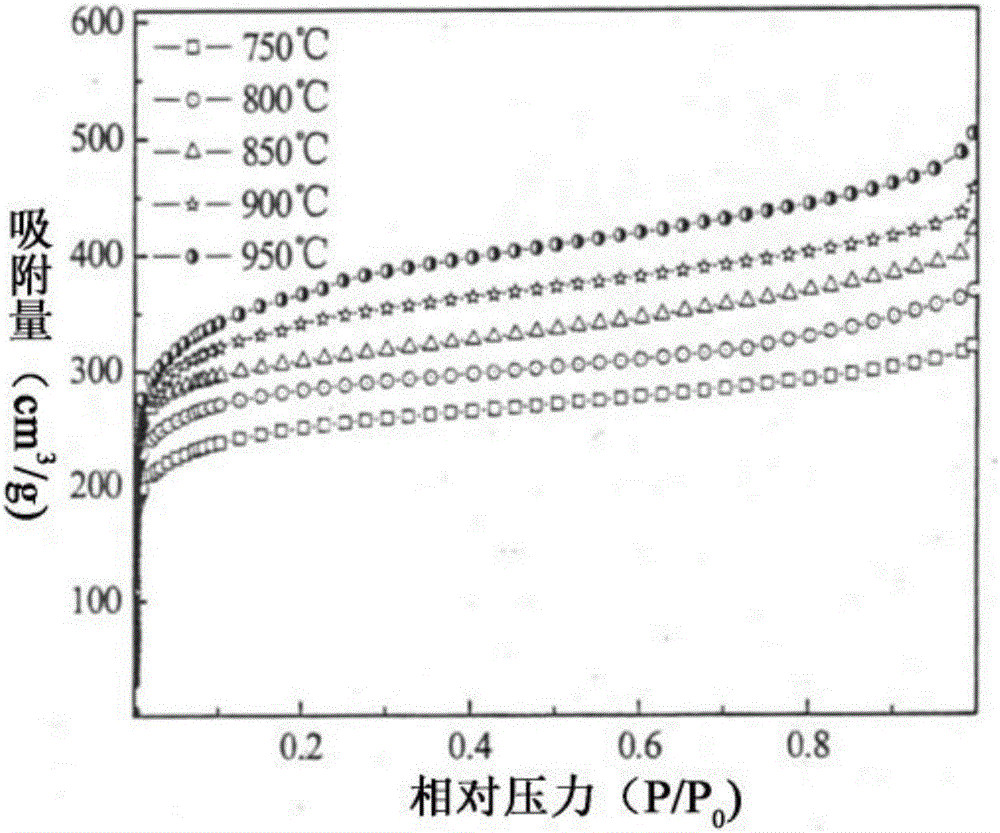

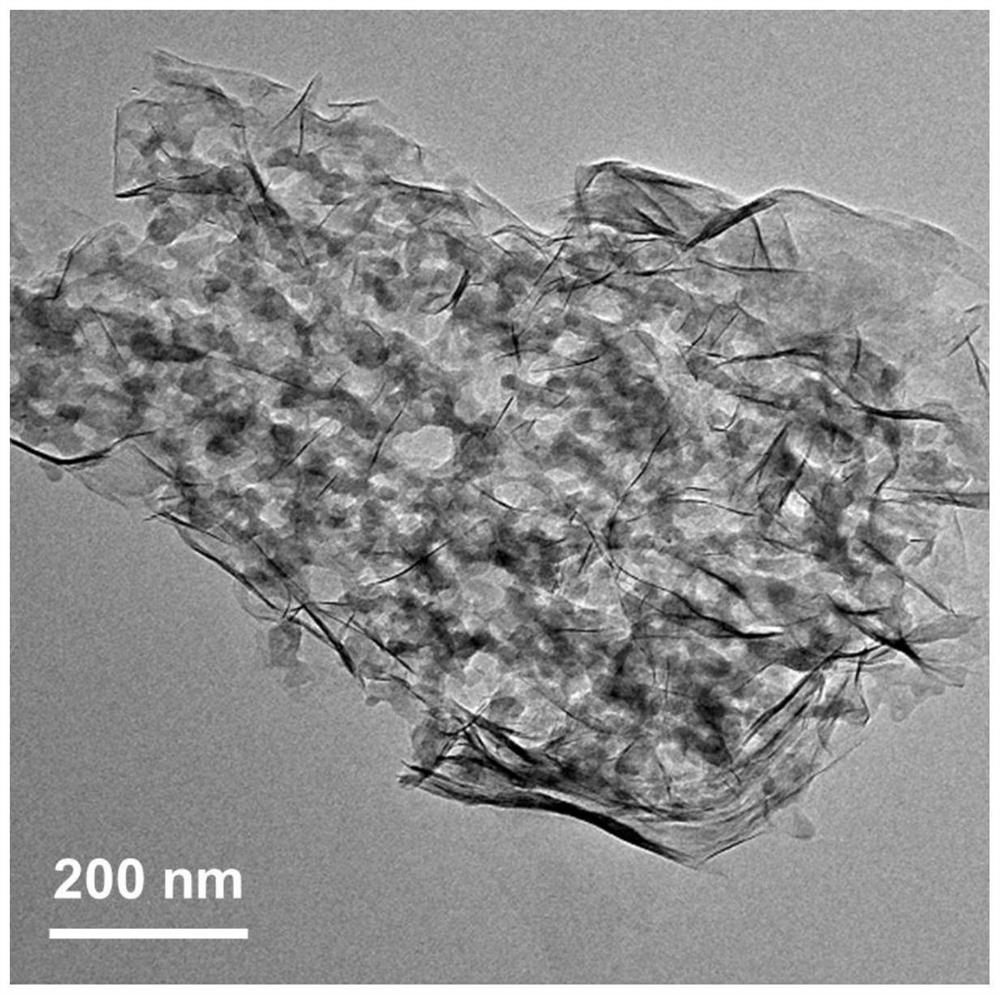

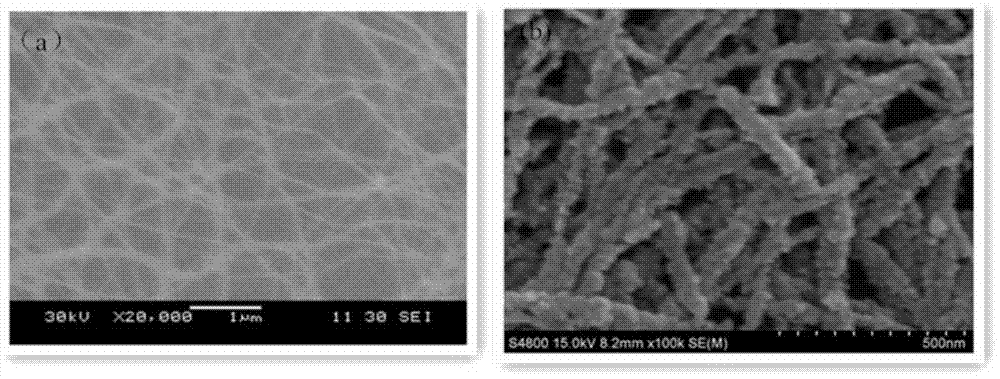

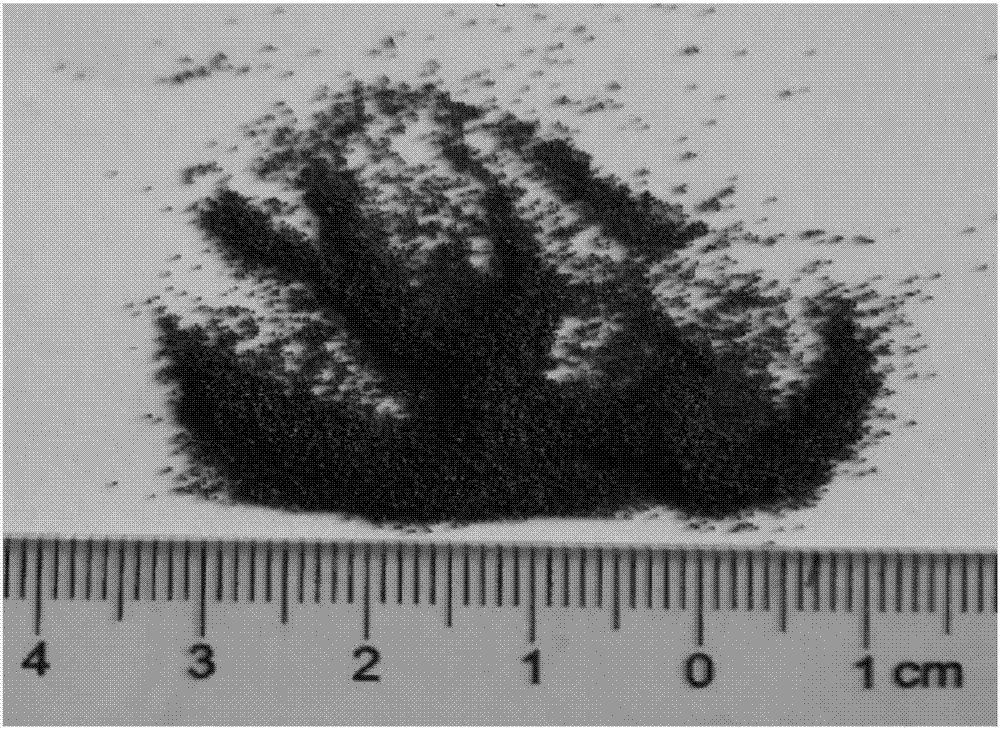

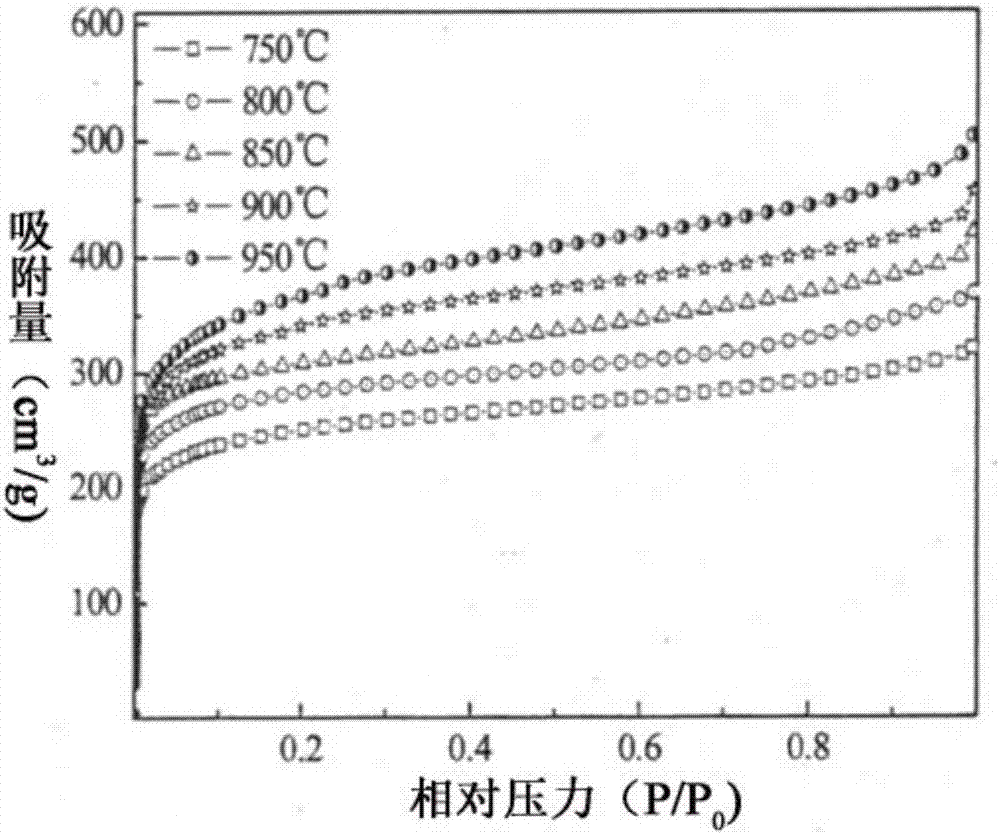

Lignin-based hierarchical porous carbon for rapidly purifying dye wastewater and preparation method of lignin-based hierarchical porous carbon

ActiveCN113289581ARealize high-value utilizationWide variety of sourcesCarbon compoundsOther chemical processesOrganic dyePorous carbon

The invention belongs to the technical field of effective utilization of low-value and waste biomass resources, and particularly discloses lignin-based hierarchical porous carbon for rapidly purifying dye wastewater and a preparation method of the lignin-based hierarchical porous carbon. The preparation method comprises the following steps: (1) dissolving lignin in a potassium hydroxide solution, uniformly conducting stirring, and conducting evaporating and concentrating to obtain a pasty thick potassium hydroxide / lignin mixture; (2) performing high-temperature carbonization and activation on the concentrated potassium hydroxide / lignin mixture in the step (1) in a nitrogen atmosphere to obtain a black carbon solid; and (3) conducting deacidification treatment, namely neutralizing the black carbon solid obtained in the step (2) with diluted hydrochloric acid, conducting washing with water until the black carbon solid is neutral, and conducting drying to obtain the lignin-based hierarchical porous carbon. The lignin-based hierarchical porous carbon prepared by the method disclosed by the invention has relatively high adsorption capacity and rapid removal capacity on anionic dyes and cationic dyes, and can realize rapid, efficient and universal adsorption of organic dyes in a water body.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing high-specific-surface-area continuous SiO2 porous fiber through natural drying method

ActiveCN105603578ASimple equipmentSave raw materialsInorganic material artificial filamentsSolventIon

The invention relates to a method for preparing high-specific-surface-area continuous SiO2 porous fiber through a natural drying method. The method includes the steps of preparing a spinning solution from silicate or silanol sol, adding the spinning solution to an acid solution coagulating bath, conducting reaction and wet spinning to obtain orthosilicic acid / silicate fiber, winding the orthosilicic acid / silicate fiber, ageing the orthosilicic acid / silicate fiber at the normal temperature, washing the orthosilicic acid / silicate fiber with deionized water to be neutral, conducting solvent replacement through ethyl alcohol, and conducting natural drying. The method has the advantages that devices are simple, raw materials are low in price and easy to obtain, the reaction process is simple and spinnability is good, the problem that inorganic porous fiber can hardly be spun into fiber is solved, and meanwhile drying of the porous fiber is achieved through natural drying. The prepared SiO2 porous fiber has abundant pores, an ultrahigh specific surface area, high temperature resistance and chemical corrosion resistance, the specific surface area of the fiber can be adjusted, and the method can be used for the fields of catalyst carriers, adsorption filtration and the like.

Owner:DONGHUA UNIV

Method for producing open tubular electrophoresis column coated with nano titanic oxide and uses thereof

InactiveCN101406828BAchieve separationAchieve enrichmentOther chemical processesComponent separationMicroparticleSolvent

The invention discloses a method for preparing an open-tube electrophoretic column coated with nanometer titanium dioxide, as well as application thereof. In an etched capillary column, an open-tube capillary electrophoretic column coated with the nanometer titanium dioxide is prepared by a water (solvent) thermal method. The preparation method is characterized in simplicity, coatings insusceptible to fall off, and the like, and is suitable for the selective enrichment and separation of functionalized phosphorylated polypeptide and protein in complex biological samples. Titanium dioxide molecules are combined with silicon hydroxyl on the surface of the inner wall of a capillary through chemical bonds, and nanometer titanium dioxide particles are uniform in grain, complete in coatings and capable of effectively reducing the nonspecific adsorption effect to the protein and other macromolecule samples. The surface properties and micropore structures of the coatings can be conveniently controlled by changing the categories and proportion of middle pore-forming agents in hydrothermal mixtures, so as to obtain a phosphorylated polypeptide capillary column with adjustable pore diameter and specific surface area.

Owner:QIQIHAR UNIVERSITY

A kind of preparation method of lithium ion battery negative electrode material based on zif complex

InactiveCN105762363BPromote circulationImproved magnification performanceCell electrodesSecondary cellsPorous carbonCharge discharge

The invention discloses a preparation method of a novel lithium ion battery negative electrode material based on a ZIF complex. The present invention synthesizes a novel imidazole zeolite organic framework compound, utilizes it to prepare a nitrogen-doped porous carbon material, and applies it to the negative electrode material of a lithium-ion battery, which can achieve a specific discharge capacity of 1211mAh / g for the first time. When the charge and discharge current density is 100mA / g, the specific capacity is almost 620mAh / g (the theoretical value of the specific capacity of the commercialized graphite negative electrode is 372mAh / g), even after 100 cycles, it reflects its good cycle performance, and when the current density is 1000mA / g, the specific capacity can reach 410mAh / g, reflecting its good rate performance.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A kind of preparation method of carbon airgel fiber

ActiveCN106012107BSolve difficult to fiber problemsGood flexibilityArtificial filaments from cellulose solutionsWet spinning methodsCelluloseFiber

The invention provides a preparation method of carbon aerogel fibers. The method comprises the following steps that a spinning stock solution is prepared; a coagulating bath is prepared; the spinning stock solution is added into the coagulating bath, wet spinning is conducted, and cellulose gel fibers are obtained; the cellulose gel fibers are subjected to winding and immersed into an ageing solution for normal temperature ageing for 15 min to 1 h, the aged cellulose gel fibers are washed to be neutral with deionized water, solvent replacement is conducted with deionized water or ethyl alcohol or tert butyl alcohol, drying is conducted, and cellulose aerogel fibers are obtained; the cellulose aerogel fibers are put into a tubular furnace to be carbonized in a nitrogen environment, and the carbon aerogel fibers are obtained. The preparation method of the carbon aerogel fibers has the advantages that the raw materials are wide in resource, low in price and easy to obtain, the preparation process is simple, the spinnability is good, and the method is green and environmentally friendly, and the problem that a carbon aerogel cannot form fibers easily is solved.

Owner:DONGHUA UNIV

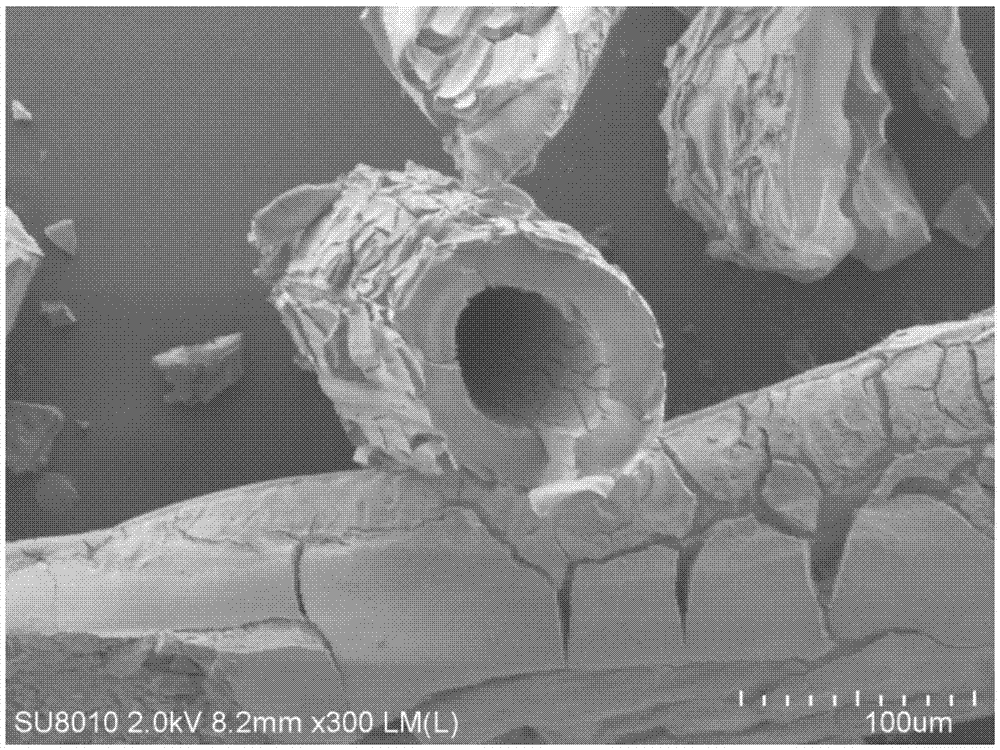

Method for preparing continuous hollow SiO2 porous fibers through non-coaxial spinning

ActiveCN105442094APracticalLarge specific surface areaInorganic material artificial filamentsPolymer scienceFiltration

The invention relates to a method for preparing continuous hollow SiO2 porous fibers through non-coaxial spinning. The method comprises steps as follows: a spinning solution is prepared from silicate; a strong acid solution is added to a coagulating basin to serve as a coagulating bath; the spinning solution is put in the coagulating bath, has a reaction and performs wet spinning, hollow orthosilicic acid / silicate fibers are obtained and subjected to winding, and the fibers after winding are immersed in an ageing solution for ageing; the fibers are washed to be neutral with deionized water after ageing, solutions in the fibers are replaced through ethanol, the fibers are dried, and the continuous hollow SiO2 porous fibers are obtained. According to the method, equipment is simple, raw materials are cheap and easy to obtain, the reaction process is simple, and the spinnability is good. The hollow inorganic SiO2 porous fibers prepared with the method have rich pores, ultrahigh specific surface area and high temperature resistance and chemical corrosion resistance, meanwhile, the specific surface area of the fibers can be adjusted, and the continuous hollow SiO2 porous fibers have more advantages in the fields such as catalysis, adsorption, filtration and the like than ordinary porous fibers.

Owner:DONGHUA UNIV

A kind of continuous cellulose airgel fiber and its preparation method

ActiveCN105970325BAdjustable specific surface areaShorten the timeArtificial filaments from cellulose solutionsWet spinning methodsCelluloseFiber

The invention provides a continuous cellulose aerogel fiber and a preparation method thereof. The preparation method comprises the following steps: dispersing cellulose into a dispersing agent so as to obtain a spinning stock solution; extruding the spinning stock solution into a coagulating bath for wet-method spinning so as to obtain cellulose aerogel fiber; winding the cellulose aerogel fiber in the coagulating bath, and soaking into an aging liquid for aging; washing the aged cellulose aerogel fiber till the pH is neutral, and drying, so as to obtain the continuous cellulose aerogel fiber. The preparation method provided by the invention has the characteristics that raw materials are cheap and easy to obtain, the preparation process is simple, green and pollution-free, the continuous cellulose aerogel fiber is good is spinnability, and the problem that cellulose aerogel is hard to spin into fiber is solved. The diameter of the cellulose aerogel fiber provided by the invention is smaller than 120 [mu]m, the cellulose aerogel fiber has the characteristics of high specific surface area (greater than or equal to 88m<2> / g), high porosity (greater than or equal to 85%), and low density (less than or equal to 0.2 / cm<3>), meanwhile the fiber specific surface area can be adjusted, and the cellulose aerogel fiber can be used in fields such as functional clothes, sensing, catalyst loading and adsorption filtration, cosmetics and biological treatment.

Owner:DONGHUA UNIV

A kind of submillimeter polystyrene-based spherical activated carbon and its preparation method and application

ActiveCN106219543BReduce manufacturing costSave raw materialsCarbon compoundsOther chemical processesCreatinine riseWater vapor

The invention discloses a submillimeter-level polystyrene-base spherical active carbon, and a preparation method and application thereof. The preparation method comprises the following steps: preparing polystyrene-base microspheres from styrene and divinylbenzene, swelling the polystyrene-base microspheres in carbon tetrachloride, adding a catalyst, and curing to form to obtain the super-crosslinked thermosetting polystyrene-base resin spheres; immersing the resin spheres in a saturated sodium chloride solution, cleaning sequentially with dilute hydrochloric acid, a sodium hydroxide solution and deionized water to a neutral state, and drying; carrying out high temperature carbonization and vapor activation to obtain polystyrene-base spherical active carbon; and carrying out surface modification on the polystyrene-base spherical active carbon by air oxidation and high-temperature nitrogen heat treatment. The preparation method is simple in technique, and lowers the production cost. The obtained spherical active carbon has the advantages of smooth surface, high sphericity and large specific area (up to 960-1400 m<2> / g), can be used for adsorbing urotoxin creatinine, and has wide application prospects in the field of uremia treatment.

Owner:CHANGZHOU YINGZHONG NANO TECH

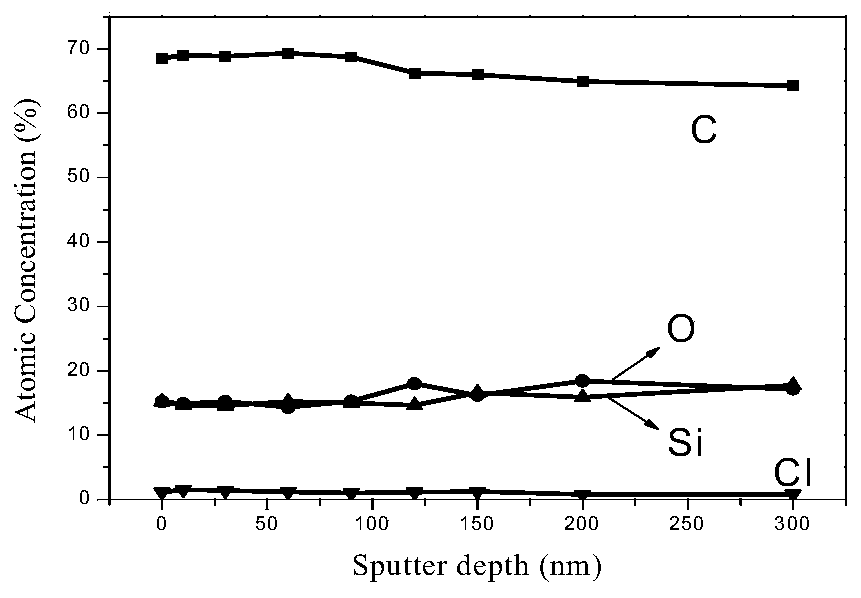

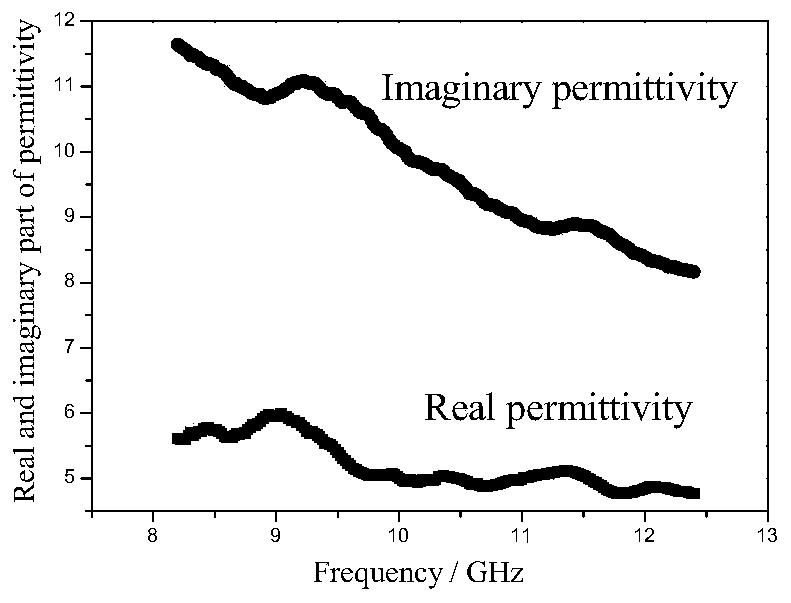

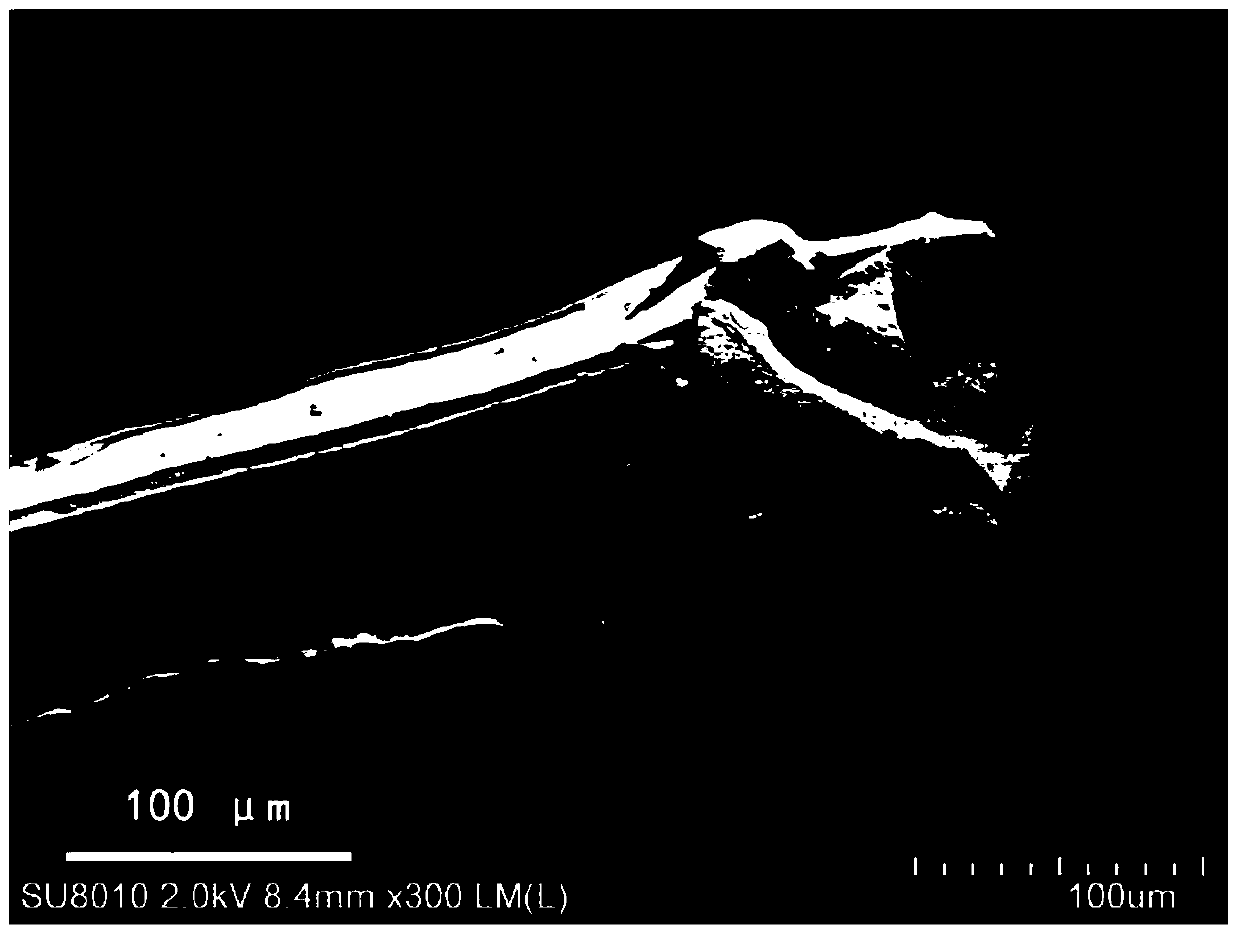

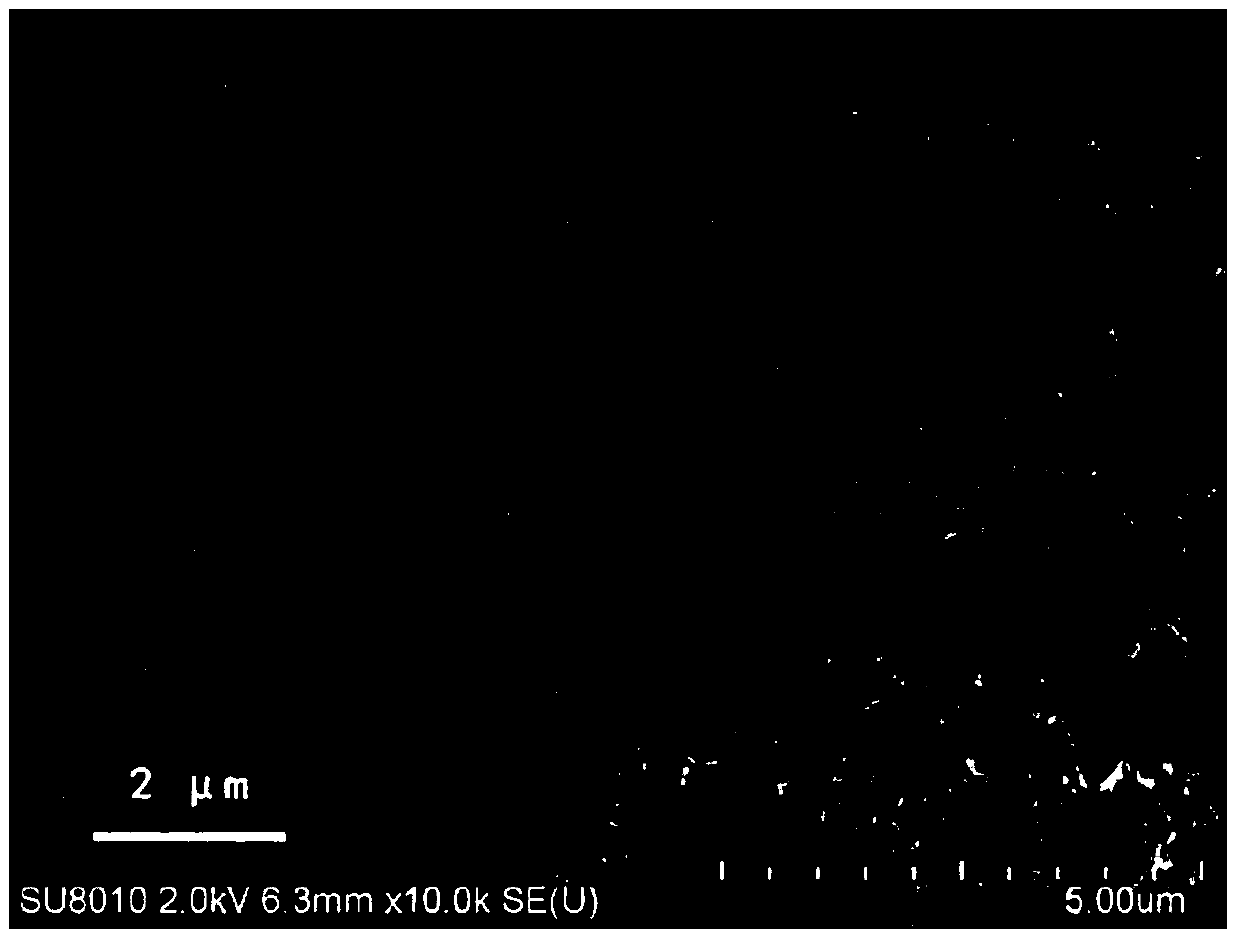

Preparation method of in situ c-sio2 composite coating on the surface of continuous sic fiber

ActiveCN107740266BLow reaction temperatureShorten the time periodInorganic material artificial filamentsFibre typesAir atmosphereRoom temperature

The invention provides a method for preparing a surface in-situ C-SiO2 composite coating of continuous SiC fibers and relates to continuous SiC fibers. The method comprises the steps: placing SiC fibers in a muffle furnace, carrying out heating in an air atmosphere, and then, carrying out furnace cooling until the temperature is room temperature in the air atmosphere, so as to obtain a degummed SiC fiber sample A; placing the degummed SiC fiber sample A in a porous graphite boat, placing the graphite boat in a heating-up tubular furnace, introducing an inert atmosphere at room temperature, andexhausting air in the tubular furnace; heating the obtained degummed SiC fiber sample A under the protection of an inert atmosphere, then, closing a N2 gas valve, opening a Cl2 gas valve, adjusting chlorine gas flow-rate, carrying out heat preservation, forming the C-SiO2 composite coating on the surface of the SiC fibers in situ through regulating and controlling a process, carrying out heat preservation, then, closing Cl2 gas, and carrying out furnace cooling until the temperature is room temperature under the protection of an inert atmosphere, thereby obtaining the surface in-situ C-SiO2 composite coating of the continuous SiC fibers.

Owner:XIAMEN UNIV

A method for preparing continuous SiO2 porous fibers with high specific surface area by natural drying method

ActiveCN105603578BAdjust the size of the specific surface areaSolve the difficult problem of spinning into fiberInorganic material artificial filamentsPolymer scienceAlcohol

The invention relates to a method for preparing high-specific-surface-area continuous SiO2 porous fiber through a natural drying method. The method includes the steps of preparing a spinning solution from silicate or silanol sol, adding the spinning solution to an acid solution coagulating bath, conducting reaction and wet spinning to obtain orthosilicic acid / silicate fiber, winding the orthosilicic acid / silicate fiber, ageing the orthosilicic acid / silicate fiber at the normal temperature, washing the orthosilicic acid / silicate fiber with deionized water to be neutral, conducting solvent replacement through ethyl alcohol, and conducting natural drying. The method has the advantages that devices are simple, raw materials are low in price and easy to obtain, the reaction process is simple and spinnability is good, the problem that inorganic porous fiber can hardly be spun into fiber is solved, and meanwhile drying of the porous fiber is achieved through natural drying. The prepared SiO2 porous fiber has abundant pores, an ultrahigh specific surface area, high temperature resistance and chemical corrosion resistance, the specific surface area of the fiber can be adjusted, and the method can be used for the fields of catalyst carriers, adsorption filtration and the like.

Owner:DONGHUA UNIV

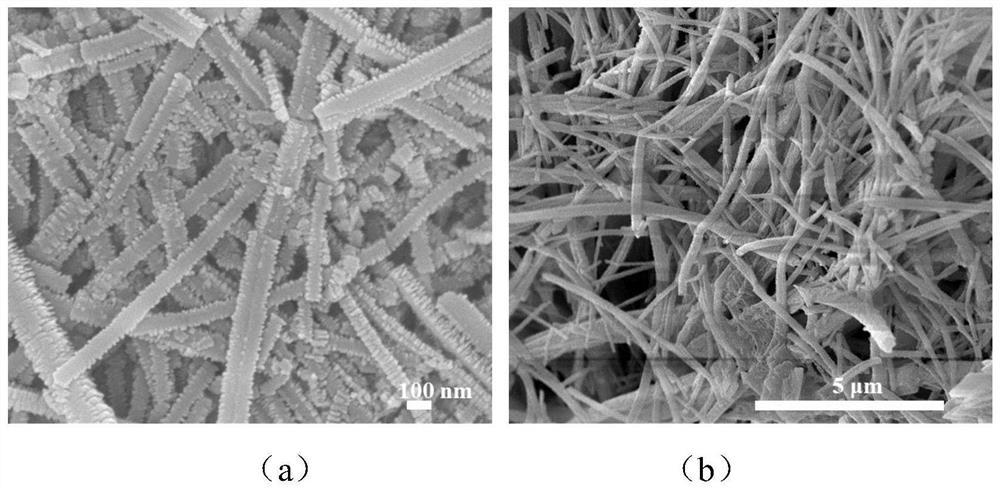

A kind of nimn MOF and its preparation method and application

ActiveCN112094415BAdjustable specific surface areaGrowth inhibitionMaterial nanotechnologyManganese oxides/hydroxidesNickel saltActive agent

The invention discloses a NiMn MOF and its preparation method and application. Using nickel salts, manganese salts and organic acids / organic acid salts containing naphthalene dicarboxylic acid as raw materials, only deionized water is used as a solvent, and through a hydrothermal method, Fabrication of heterojunction composite MOFs with linear ribbon-like Mn MOF grown on sheet-like Ni MOF. The NiMn MOF prepared by this method has the characteristics of controllable morphology and composition. This method does not need to add templates or surfactants, and has the advantages of low reaction temperature, simple operation and easy control, and environmental friendliness.

Owner:XI AN JIAOTONG UNIV

A kind of preparation method of toughness sio2 airgel fiber with post-treatment of isocyanate

ActiveCN105442099BAdjust the size of the specific surface areaTo achieve toughening and strengtheningInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberPolymer science

The invention relates to a preparation method of tough SiO2 aerogel fibers post-processed through isocyanate. The preparation method comprises steps as follows: a spinning solution is prepared from silicate or silanol sol; an acid solution is used for a coagulating bath; the spinning solution is added to the coagulating bath, the mixture has a reaction, wet spinning is performed, orthosiliconic acid / silicate fibers are obtained, wound, aged, washed, soaked in a tetrahydrofuran solution of isocyanate for 48 h, then taken out and washed with acetone, solvent replacement is performed through water or ethanol, and the tough SiO2 aerogel fibers are obtained after drying. The method has the characteristics that the raw materials are cheap and easy to obtain, the reaction process is simple, and the spinnability is good; the SiO2 aerogel fibers are toughened through high polymers, the prepared tough SiO2 aerogel fibers have rich pores, a high specific surface area and certain toughness and is high-temperature-resistant and chemical-corrosion resistant, and the specific surface area of the fibers is adjustable.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com