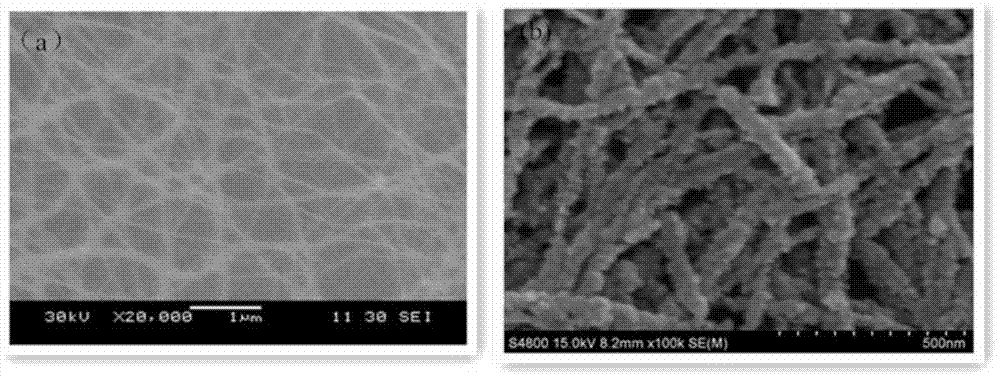

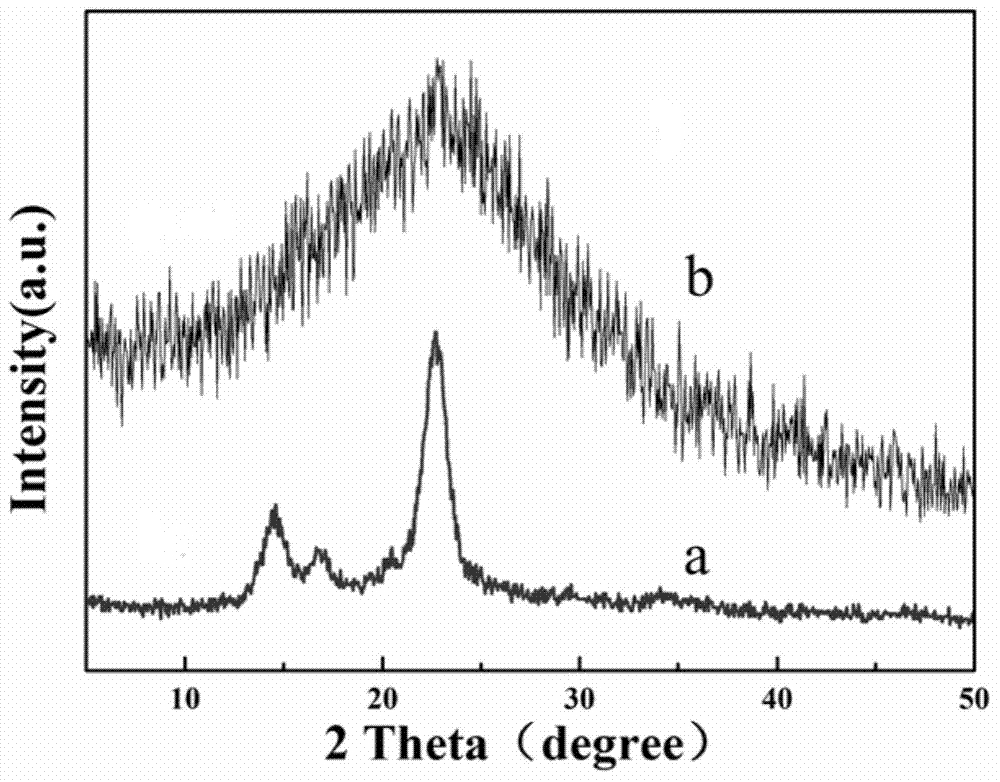

Bacterial cellulose membrane/porous carbon adsorbent and preparation thereof

A technology of bacterial cellulose membrane and adsorbent is applied in the field of bacterial cellulose membrane/porous carbon adsorbent and its preparation, which can solve the problems such as the inability to strictly control air PM2.5, and achieve the effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Acetobacter xylinum was used for seed amplification, cultured on a shaking table, the culture temperature was 30°C, the speed of the shaker was 160 rpm, and the culture time was 36 h;

[0036] Step 2: Add 10 g / L sodium carboxymethyl cellulose when preparing the fermentation broth; after the sodium carboxymethyl cellulose is completely dissolved, add 1 g / L calcium carbonate, sonicate for 60 minutes, and sterilize at 121°C for 20 minutes , cooled to room temperature;

[0037] Step 3: Acetobacter xylinum is inoculated with an inoculum of 8%, cultured after inoculation, and cultivated for 5 days;

[0038] Step 4: After the fermentation is over, use NaOH with a mass fraction of 3 g / L and H at 3 g / L 2 o 2 Water bath at 80°C for 3.0 hours to remove residual cells and fermentation broth;

[0039] Step 5: Soak the BC membrane with 20 g / L acetic acid for 24 h to remove the calcium carbonate embedded in the cellulose network;

[0040] Step 6: Rinse the BC membrane with...

Embodiment 2

[0042] The first step: Acetobacter xylinum was used for seed amplification, cultured on a shaking table, the culture temperature was 29°C, the speed of the shaker was 160 rpm, and the culture time was 36 h;

[0043] Step 2: Add 10 g / L sodium carboxymethyl cellulose when preparing the fermentation broth; after the sodium carboxymethyl cellulose is completely dissolved, add 3 g / L calcium carbonate, sonicate for 20 minutes, and sterilize at 115°C for 25 minutes , cooled to room temperature;

[0044] Step 3: Acetobacter xylinum is inoculated with an inoculum of 8%, cultured after inoculation, and cultivated for 5 days;

[0045] Step 4: After the fermentation is over, use 4 g / L of NaOH and 4 g / L of H 2 o 2 Water bath at 85°C for 2.0 hours to remove residual cells and fermentation broth;

[0046] Step 5: Soak the BC membrane with 30 g / L acetic acid for 24 h to remove the calcium carbonate embedded in the cellulose network;

[0047] Step 6: Rinse the BC membrane with deionized wa...

Embodiment 3

[0049] The first step: Acetobacter xylinum was used for seed amplification, and the culture was shaken on a shaking table, the culture temperature was 31°C, the speed of the shaker was 160 rpm, and the culture time was 42 h;

[0050] Step 2: Add 15 g / L sodium carboxymethyl cellulose when preparing the fermentation broth; after the sodium carboxymethyl cellulose is completely dissolved, add 4 g / L calcium carbonate, sterilize at 121°C for 15 minutes, and cool to room temperature;

[0051] The third step: Acetobacter xylinum is inoculated with 10% inoculation amount, and after inoculation, it is cultured statically and cultivated for 7 days;

[0052] Step 4: After the fermentation is over, use a NaOH solution with a mass fraction of 5 g / L and 5 g / L of H 2 o 2 Water bath at 75°C for 3.0 hours to remove residual cells and fermentation broth;

[0053] Step 5: Soak the BC membrane with 40 g / L acetic acid for 36 h to remove the calcium carbonate embedded in the cellulose network; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com