Preparation method of resin used for blood purification to remove β2-microglobulin

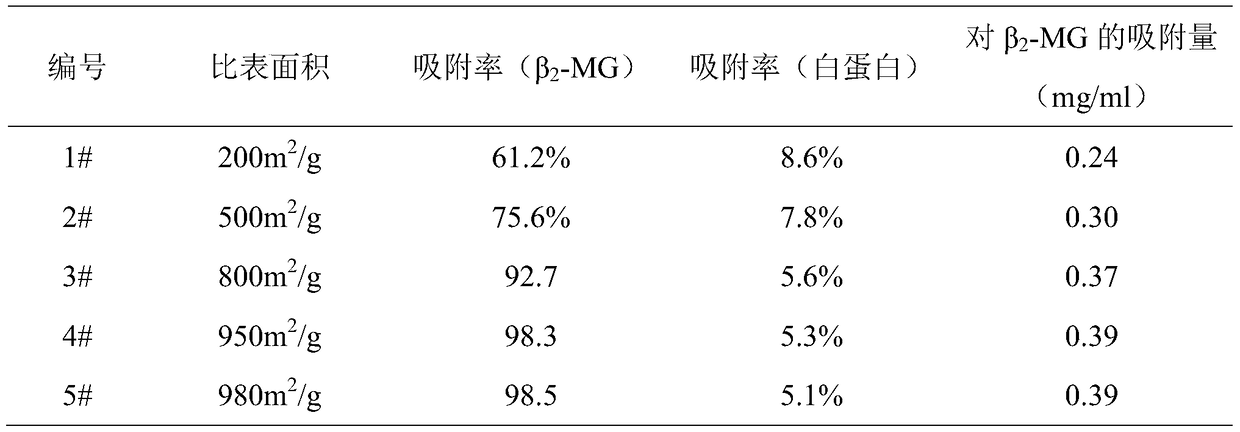

A microglobulin and blood purification technology, applied in the field of biomedical engineering, can solve the problems of limited curative effect and limited removal of microglobulin, and achieve the effects of high adsorption performance, large-scale production and preparation, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind for blood purification to remove beta 2 -Preparation method of microglobulin resin:

[0020] Step 1. First, prepare polystyrene-divinylbenzene microspheres;

[0021] Prepare the oil phase with p-styrene and divinylbenzene monomers at a mass ratio of 1:1, and add 0.5wt% initiator of the mixture of p-styrene and divinylbenzene and porogen less than 5wt%, adopt suspension polymerization Method: adding 3wt% stabilizer of a mixture of p-styrene and divinylbenzene, adding the oil phase to 80°C water and stirring for 12 hours to prepare polystyrene-divinylbenzene microspheres with ultra-high crosslinking degree. The polystyrene-divinylbenzene microspheres are cleaned with water or acetone and dried;

[0022] The initiator is benzoyl peroxide, the porogen is a mixture of any two of toluene, naphthalene, paraffin oil, benzene, and dodecane, and the stabilizer is gelatin.

[0023] Step 2. Next, chloromethylate polystyrene-divinylbenzene microspheres;

[0024] After the polystyrene...

Embodiment 2

[0029] A kind for blood purification to remove beta 2 -Preparation method of microglobulin resin:

[0030] Step 1. First, prepare polystyrene-divinylbenzene microspheres;

[0031] Prepare the oil phase with p-styrene and divinylbenzene monomers in a mass ratio of 1:2, and add 1wt% initiator of the mixture of p-styrene and divinylbenzene and 40wt% or less porogen at the same time, adopt the suspension polymerization method , Adding 10wt% stabilizer of a mixture of p-styrene and divinylbenzene, adding the oil phase to 80°C water, stirring and reacting for 24 hours to prepare polystyrene-divinylbenzene microspheres with ultra-high cross-linking degree. The styrene-divinylbenzene microspheres are cleaned with water or acetone and dried;

[0032] The initiator is benzoyl peroxide, the porogen is any one of toluene, naphthalene, paraffin oil, benzene, and dodecane, and the stabilizer is polyvinyl alcohol.

[0033] Step 2. Next, chloromethylate polystyrene-divinylbenzene microspheres;

[003...

Embodiment 3

[0039] A kind for blood purification to remove beta 2 -Preparation method of microglobulin resin:

[0040] Step 1. First, prepare polystyrene-divinylbenzene microspheres;

[0041] The p-styrene and divinylbenzene monomers are configured in the oil phase at a mass ratio of 1:1.5, and 0.8wt% of the initiator and 20wt% of the porogen of the mixture of p-styrene and divinylbenzene are added, and the suspension polymerization is adopted. Method, adding 5wt% stabilizer of a mixture of p-styrene and divinylbenzene, adding the oil phase to 80℃ water and stirring for 16 hours to prepare polystyrene-divinylbenzene microspheres with super high crosslinking degree, and then The polystyrene-divinylbenzene microspheres are cleaned with water or acetone and dried;

[0042] The initiator is benzoyl peroxide, the porogen is any one of toluene, naphthalene, paraffin oil, benzene, and dodecane, or a mixture of any two, and the stabilizer is polyvinyl alcohol Or gelatin.

[0043] Step 2. Next, chlorome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com