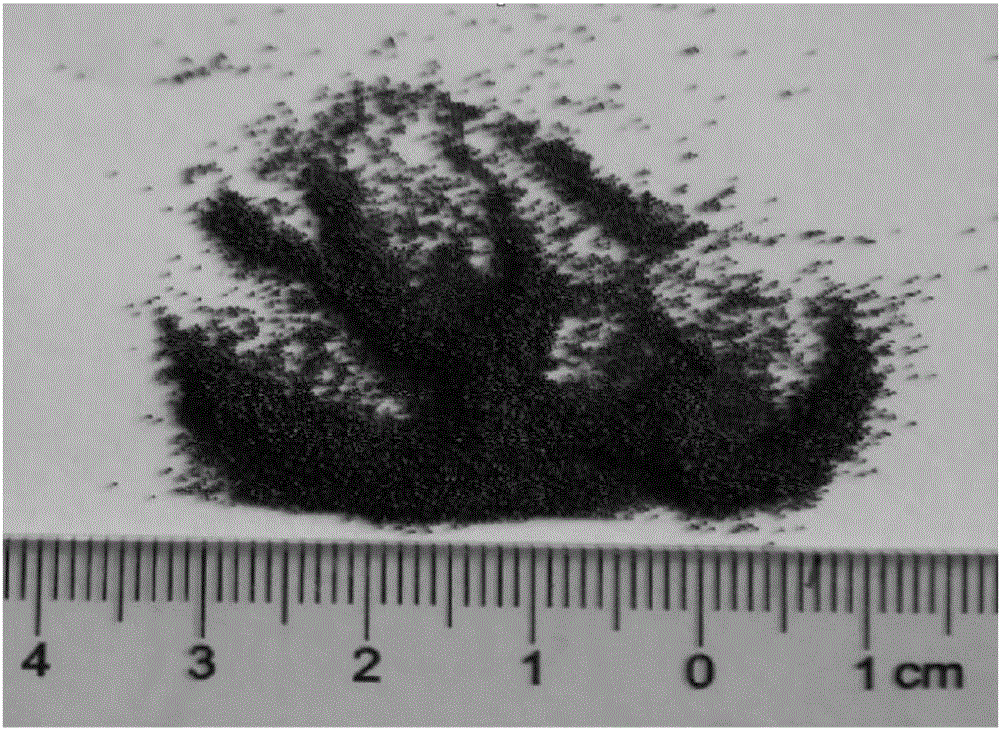

Submillimeter-level polystyrene-base spherical active carbon, and preparation method and application thereof

A polystyrene-based, sub-millimeter technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the complex production process of phenolic resin, the high cost of spherical activated carbon, and the price of phenol. Expensive and other problems, to achieve the effect of easy industrial production, good sphericity, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

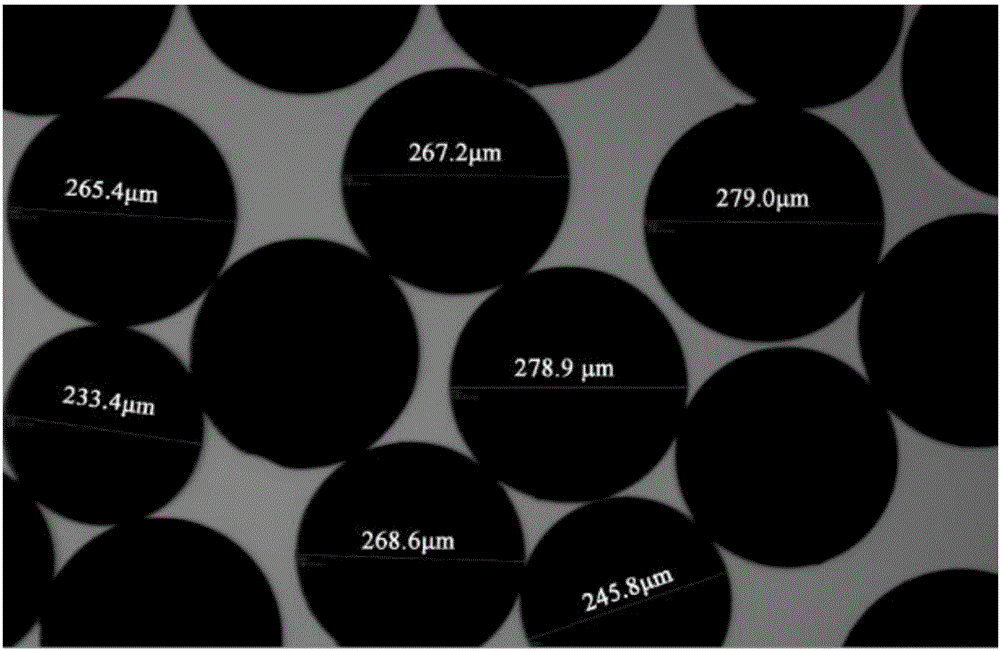

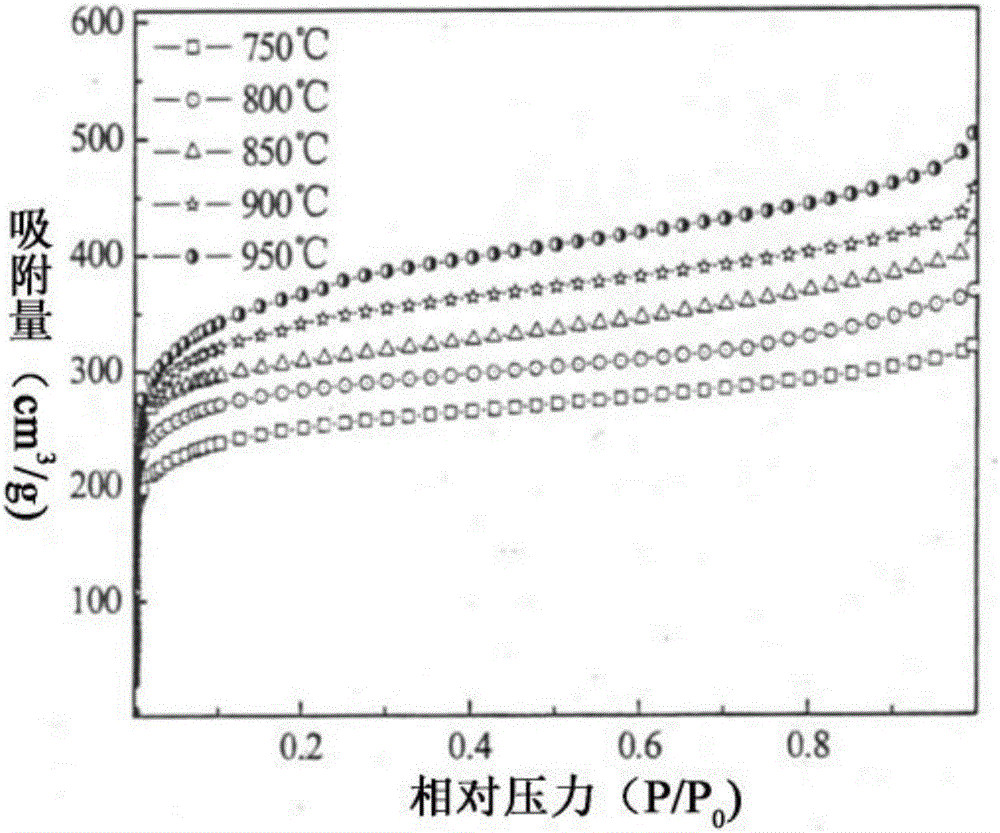

[0033] A preparation method of submillimeter polystyrene-based spherical activated carbon, comprising the following steps:

[0034] (1) fully mix the reaction monomer 5g styrene and 40g divinylbenzene in a three-necked flask to obtain a mixed monomer, and add 0.25g initiator dibenzoyl peroxide to the mixed monomer, stir, and make the peroxidized Benzoyl was fully dissolved, then 0.45g porogen n-pentane was added, and oil phase A was made after fully stirring; 900g deionized water was added to a three-necked flask equipped with an electric stirrer, a thermometer and a condenser tube, and the Add 18g of dispersant gelatin to deionized water, and add 90g of sodium chloride to prevent the polymerization of polar monomers in water, heat slowly and fully stir to form water phase B, stop stirring after heating up to 55°C; Slowly add phase A into water phase B, fully exclude oxygen, and then raise the temperature to 90°C at a rate of 10°C / min, keep the temperature constant for 3 hours...

Embodiment 2

[0041] A preparation method of submillimeter polystyrene-based spherical activated carbon, comprising the following steps:

[0042](1) Fully mix the reaction monomer 20g styrene and 20g divinylbenzene in a three-necked flask to obtain a mixed monomer, and add 0.2g initiator dibenzoyl peroxide to the mixed monomer, stir, and make the peroxidized Benzoyl is fully dissolved, then add 0.3g of porogen n-pentane, fully stir to form oil phase A; add 150g of deionized water to a three-necked flask equipped with an electric stirrer, a thermometer and a condenser tube, and then add Add 0.5g of dispersant gelatin to deionized water, and add 7.5g of sodium chloride to prevent the polymerization of polar monomers in water, heat slowly and fully stir to form water phase B, stop stirring after heating up to 55°C; configure the above Slowly add the oil phase A into the water phase B, fully remove the oxygen, and then raise the temperature to 90°C at a rate of 5°C / min, keep the temperature for...

Embodiment 3

[0049] A preparation method of submillimeter polystyrene-based spherical activated carbon, comprising the following steps:

[0050] (1) In a three-necked flask, the reaction monomer 30g styrene and 10g divinylbenzene are fully mixed to obtain a mixed monomer, and 0.4g initiator dibenzoyl peroxide is added in the mixed monomer, stirred, and the peroxidized Benzoyl is fully dissolved, then add 0.2g porogen n-pentane, and stir well to form oil phase A; add 600g deionized water to a three-necked flask equipped with an electric stirrer, a thermometer and a condenser tube, Add 6g of dispersant gelatin to deionized water, and add 25g of sodium chloride to prevent the polymerization of polar monomers in the water, heat slowly and fully stir to form water phase B, stop stirring after heating up to 55°C; Slowly add phase A into water phase B, fully remove oxygen and then raise the temperature to 70°C at a rate of 1°C / min, keep the temperature for 1h, filter, dry in vacuum, and obtain po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com