Porous ultra-high molecular weight poly fluorine-containing olefin hollow microspheres and preparation method thereof

An ultra-high molecular weight, fluorine-containing olefin technology, applied in the field of porous ultra-high molecular weight polyfluorine-containing olefin hollow microspheres and their preparation, can solve the problem that the viscosity of the polymer solution cannot meet the requirements of lithium batteries, the polymer molecular weight is low, and the production efficiency low problems, to achieve the effect of excellent industrialization prospects, excellent mechanical properties, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of a porous ultra-high molecular weight polyfluoroolefin microsphere of the present invention adopts a metal nanoparticle catalyzed polymerization reaction system, and the polymerization method is suspension polymerization, comprising the following steps:

[0026] (1) The reaction kettle is evacuated and then filled with nitrogen to replace the air in the reaction kettle. The second monomer, catalyst, initiator, dispersant and deionized water are added in a certain mass ratio, and the reaction kettle is closed. Monomer: catalyst: initiator: dispersant: deionized water= 5~20: 0.0001~0.01: 0.1~1.0: 0.1~1.0: 300~800;

[0027] (2) The reaction kettle is heated to 30~60℃, the stirring speed is maintained at 500~1500 r / min, the porogen is added according to a certain mass ratio, and the stirring is uniform, wherein the second monomer: porogen=5~20: 0.1 ~1.0;

[0028] (3) Keep the temperature of the reaction kettle at 30~60°C, maintain the stirring spee...

Embodiment 1

[0033] First close the reaction kettle, vacuumize the reaction kettle, and then fill with nitrogen in a vacuum state to replace the air in the reaction kettle. In a stainless steel autoclave equipped with stirring, through the equipment feeding device, add 600 g of deionized water, 10 g of hexafluorobutyl methacrylate, 0.001 g of silver nanoparticles (spherical), 0.8 g of ethyl 2-bromoisobutyrate ester, 0.3 g polyvinyl alcohol, 0.3 g n-pentane.

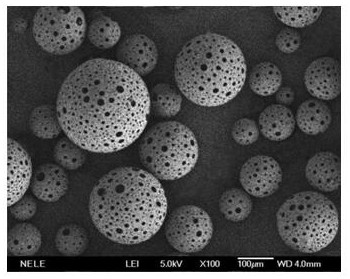

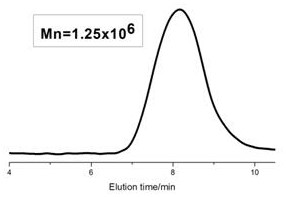

[0034] The temperature of the reaction kettle was maintained at 50 °C, the stirring speed was maintained at 500 r / min, and the pressure of the kettle was increased to 3.5 MPa by filling with vinylidene fluoride. Maintained at 50 °C, the polymerization reaction time was 10 h. After the reaction is completed, the stirring is stopped, and the polymer product is centrifuged, washed and dried to obtain porous ultra-high molecular weight polyvinylidene fluoride hollow microspheres.

[0035] Measurement of particle size and pore size of mi...

Embodiment 2

[0039]First close the reaction kettle, vacuumize the reaction kettle, and then fill with nitrogen in a vacuum state to replace the air in the reaction kettle. In a stainless steel autoclave equipped with stirring, through the equipment feeding device, add 800 g of deionized water, 5 g of hexafluorobutyl methacrylate, 0.0001 g of silver nanoparticles (spherical), 0.1 g of ethyl 2-bromoisobutyrate ester, 0.1 g polyvinyl alcohol, 0.1 g n-pentane.

[0040] The temperature of the reaction kettle was maintained at 30 °C, the stirring speed was maintained at 800 r / min, and the pressure of the kettle was increased to 2.8 MPa by filling with vinylidene fluoride. Maintained at 30 °C, the polymerization reaction time was 15 h. After the reaction is completed, the stirring is stopped, and the polymer product is centrifuged, washed and dried to obtain porous ultra-high molecular weight polyvinylidene fluoride hollow microspheres.

[0041] The test procedure in Example 1 was repeated. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com