Preparation method for lithium battery anode material by taking metal organic frame as template

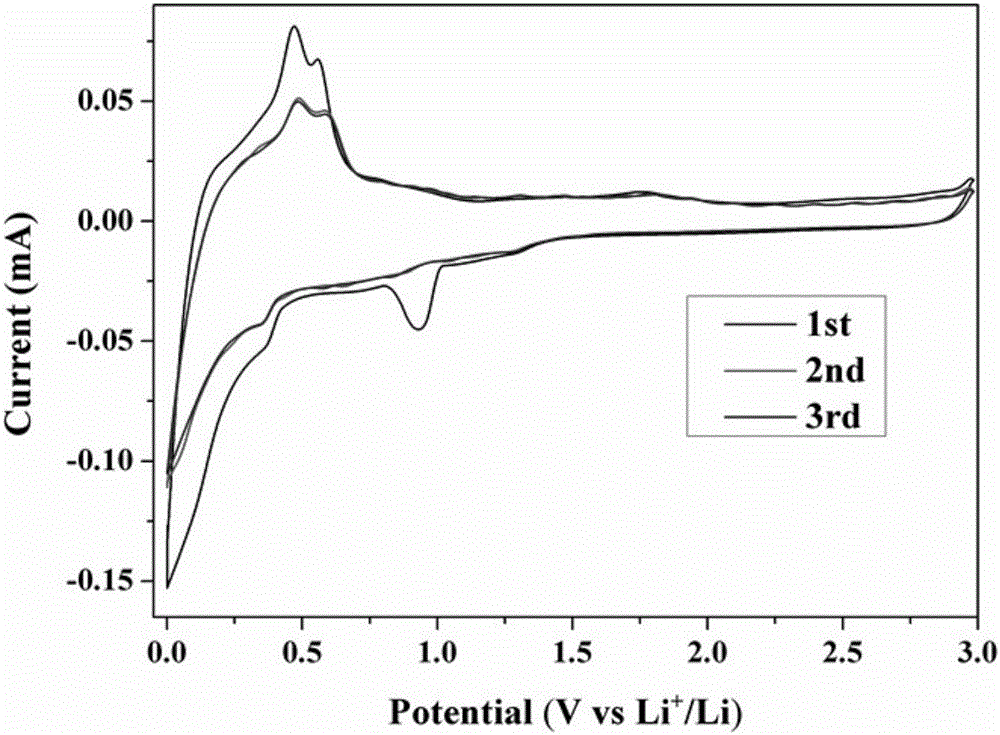

A metal-organic framework, negative electrode material technology, applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve problems such as small specific capacity, achieve high charge-discharge specific capacity, high Coulomb efficiency, good cycle stability and Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation method of the negative electrode material of lithium battery with metal organic framework as the template of the present invention, comprises the following steps:

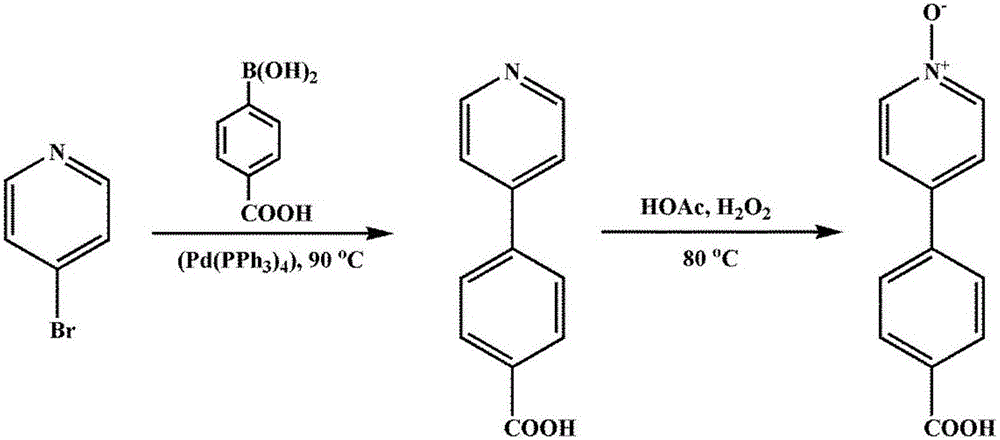

[0031] (1) Synthesis of organic ligand 4-p-methylphenyl-pyridine oxide (4,4-Hopybz): Weigh 4-bromopyridine hydrochloride, 4-carboxyphenylboronic acid and sodium carbonate into toluene, add four Triphenylphosphopalladium is used as a catalyst, after reacting at 80-100°C for 10-14h in a nitrogen atmosphere, filter the clear night, adjust the pH to acidic, precipitate and filter to obtain a white intermediate product; dry the intermediate product, add glacial acetic acid and hydrogen peroxide , After heating the reaction, the 4,4-Hopybz organic ligand was obtained by filtration.

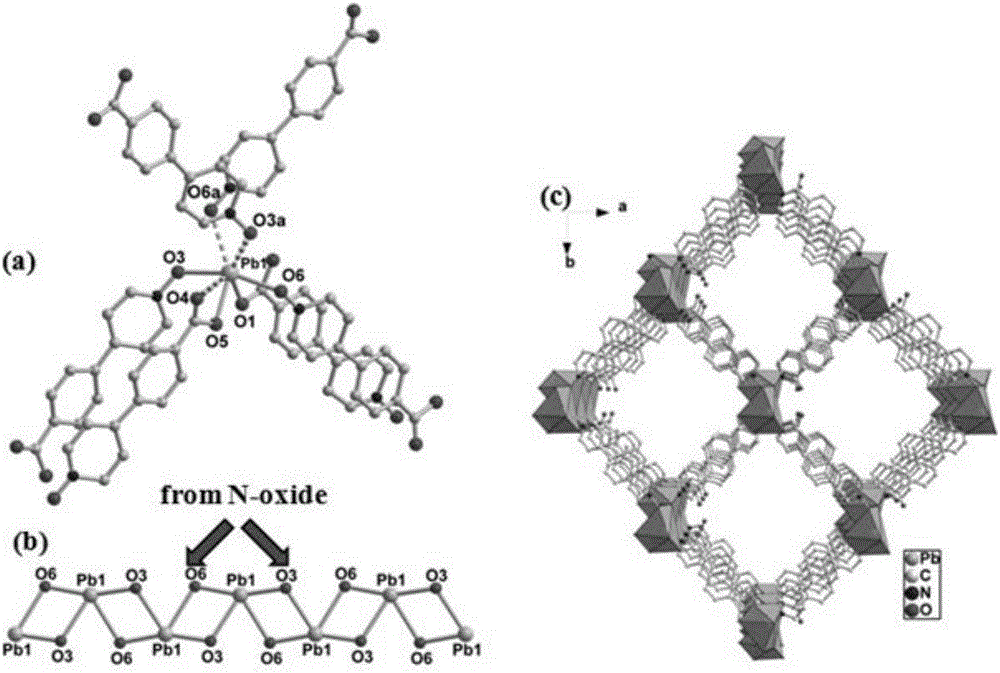

[0032] (2) Synthesis of Pb-MOF material: Weigh Pb(NO 3 ) 2 Dissolve the ligand 4,4-Hopybz in the solvent, heat the reaction in the reactor, and cool down to room temperature after the reaction to obtain the Pb-...

Embodiment 1

[0040] This example describes in detail the preparation method of the lithium battery negative electrode material using the metal organic framework as the template.

[0041] A kind of preparation method of the lithium battery negative electrode material of the present invention using metal organic framework as template, comprises the following steps:

[0042] (1) Synthesis of organic ligand 4-p-methylphenyl-pyridine oxide (4,4-Hopybz)

[0043] see figure 1 , which is a schematic diagram of the synthesis reaction steps of the organic ligand in the present invention. Take by weighing 8mmol of 4-bromopyridine hydrochloride, 8mmol of 4-carboxyphenylboronic acid and 10mmol of anhydrous sodium carbonate and join in the toluene solution, add 0.01mmol of tetrakis triphenyl phosphopalladium, in catalyst tetrakis triphenyl Under the action of phospho-palladium and in a nitrogen atmosphere, react at 90 ° for 12 hours, filter to collect clear night, add dilute hydrochloric acid to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com