Lignin-based hierarchical porous carbon for rapidly purifying dye wastewater and preparation method of lignin-based hierarchical porous carbon

A lignin-based, dye-based wastewater technology, applied in chemical instruments and methods, inorganic chemistry, water pollutants, etc., can solve the problems of not meeting the needs of use, insufficient adsorption capacity, complicated preparation process, etc., to achieve high value The effect of utilization, low price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

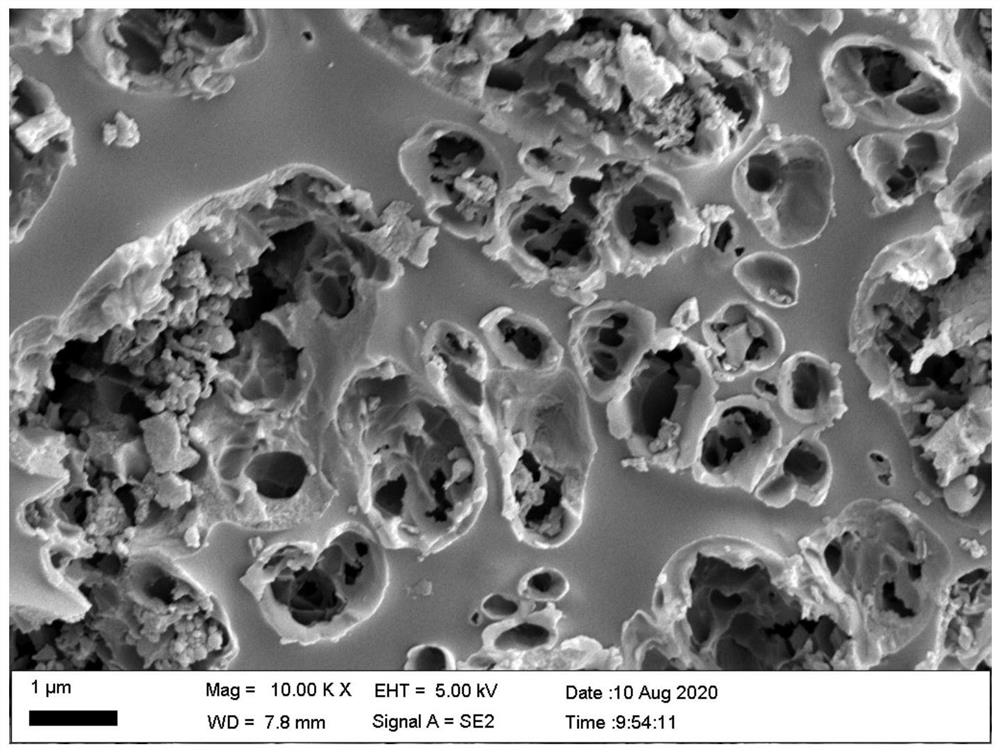

[0039] Preparation steps of lignin-based hierarchical porous carbon:

[0040](1) Dissolve enzymatic lignin in potassium hydroxide solution, stir evenly, evaporate and concentrate at 80°C for 2 hours to obtain a paste-like viscous mixture, wherein the concentration of potassium hydroxide solution is 25g / L, The mass ratio of potassium and enzymatic lignin is 1:10;

[0041] (2) Under a nitrogen atmosphere, place the concentrated potassium hydroxide / enzymatic lignin mixture in a tube furnace for high-temperature carbonization activation at a heating rate of 5°C / min to 200°C, and then Raise the temperature to 500°C at a heating rate of 1°C / min, then raise the temperature to 700°C at a heating rate of 2°C / min, and keep it for 0.5h to obtain a black carbon solid;

[0042] (3) The black carbon solid obtained in step (2) was first neutralized with 2% dilute hydrochloric acid, then washed with water until neutral, and dried at 105°C for 12 hours to obtain lignin-based hierarchical poro...

Embodiment 2

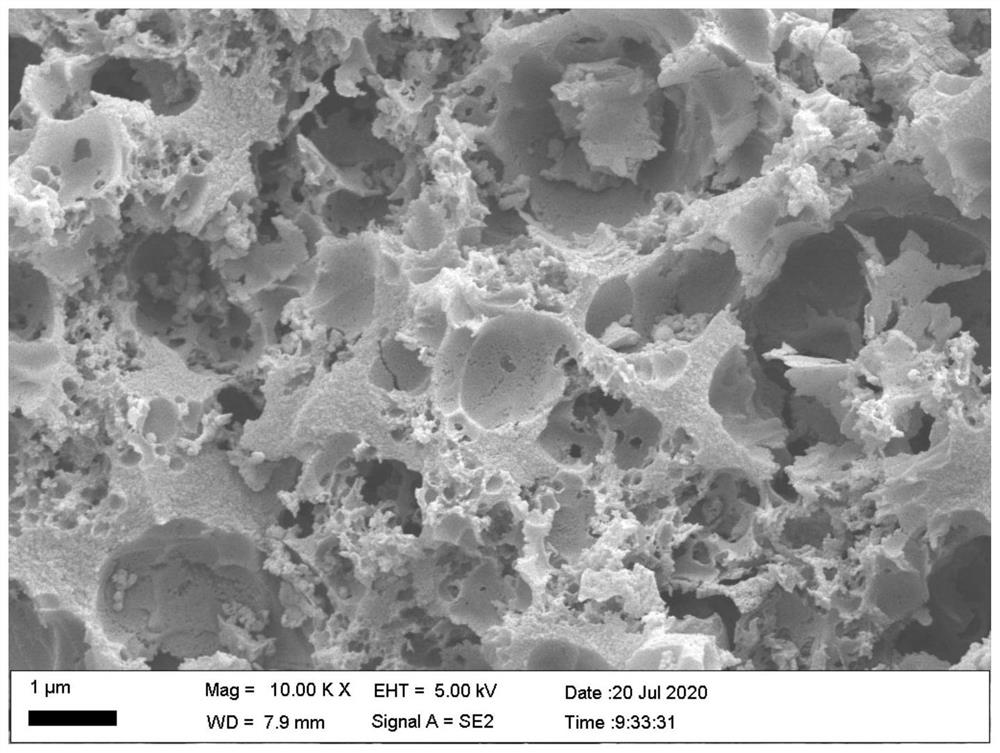

[0046] Preparation steps of lignin-based hierarchical porous carbon:

[0047] (1) Dissolve the organic solvent lignin in the potassium hydroxide solution, stir evenly, evaporate and concentrate at a temperature of 90°C for 4 hours to obtain a paste-like viscous mixture, wherein the concentration of the potassium hydroxide solution is 50g / L, and the hydrogen oxidized The mass ratio of potassium and organic solvent lignin is 1:5;

[0048] (2) Under nitrogen atmosphere, place the potassium hydroxide / organic solvent lignin mixture concentrated in step (1) in a tube furnace for high-temperature carbonization activation, and raise the temperature to 200° C. at a heating rate of 5° C. / min, and then Raise the temperature to 500°C at a heating rate of 1°C / min, and then raise the temperature to 800°C at a heating rate of 2°C / min, and keep it for 1 hour to obtain a black carbon solid;

[0049] (3) The black carbon solid obtained in step (2) was first neutralized with 2% dilute hydrochlo...

Embodiment 3

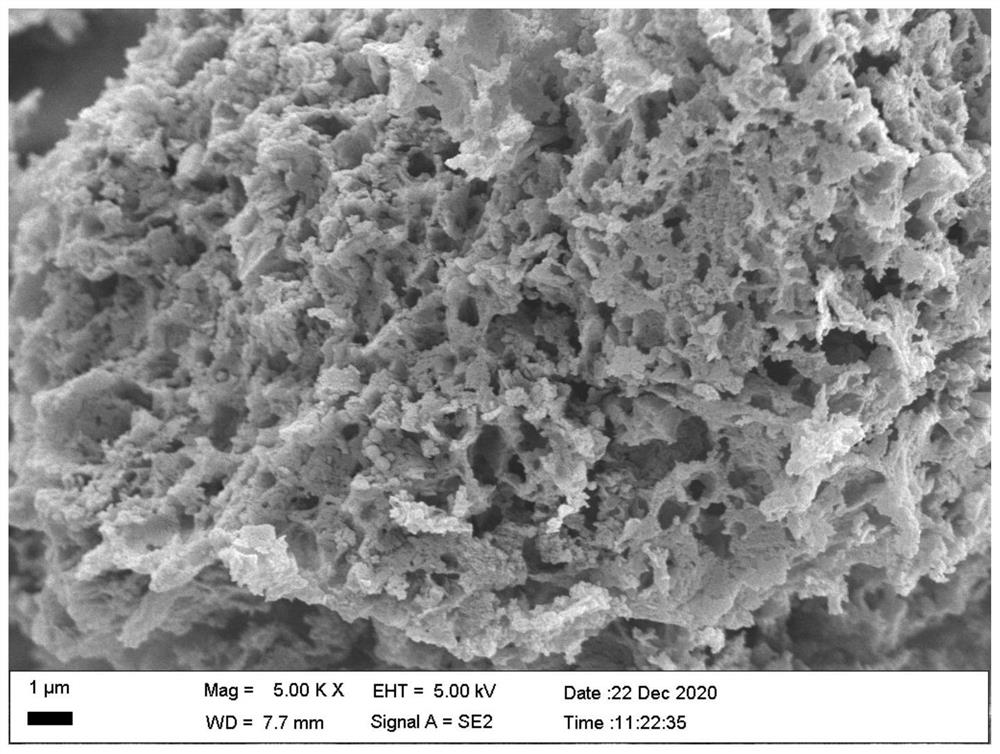

[0053] Preparation steps of lignin-based hierarchical porous carbon:

[0054] (1) Dissolve lignosulfonate in potassium hydroxide solution, stir evenly, evaporate and concentrate at a temperature of 100°C for 6 hours to obtain a paste-like viscous mixture, wherein the concentration of potassium hydroxide solution is 75g / L, hydrogen The mass ratio of potassium oxide and lignosulfonate is 3:10;

[0055] (2) Under a nitrogen atmosphere, place the potassium hydroxide / lignosulfonate mixture concentrated in step (1) in a tube furnace for high-temperature carbonization activation, and heat up to 200° C. at a heating rate of 5° C. / min. Then raise the temperature to 500°C at a heating rate of 1°C / min, and then raise the temperature to 800°C at a heating rate of 2°C / min, and keep it warm for 1.0h to obtain a black carbon solid;

[0056] (3) The black carbon solid obtained in step (2) was first neutralized with 2% dilute hydrochloric acid, then washed with water until neutral, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com