Method for preparing recyclable efficient heavy metal ion adsorbents

A technology of heavy metal ions and adsorbents, which is applied in the fields of alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of low adsorption efficiency and non-recyclable use of metal ion adsorbents, and achieve rich pores and surface rough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

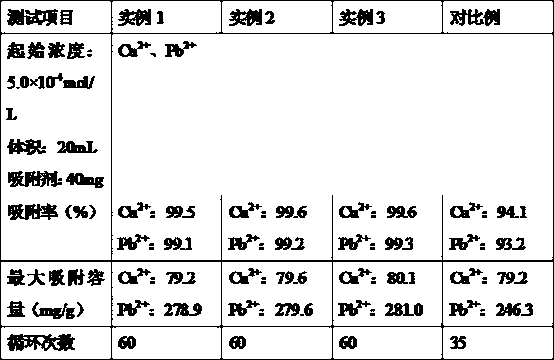

Examples

example 1

[0029] Weigh 100% of the sodium silicate solution with a mass fraction of 40%, pour it into a three-neck flask with a stirrer, slowly adjust the pH to 6 with hydrochloric acid with a mass fraction of 10%, start the stirrer, and stir at a speed of 350r / min for 30min , microwave oscillating treatment for 3 minutes, set the microwave oscillating power to 700W to obtain nano-hydrosol, put the nano-hydrosol in an oven and heat up to 80°C, and dry for 3 hours to obtain nano-silica gel; weigh 200g of nano-silica gel and put it in 400mL mass fraction In a 40% aqueous solution of methanesulfonic acid, control the temperature at 50°C, stir for 20 minutes to obtain activated silica gel, mix activated silica gel with chloropropyltrimethoxysilane in a mass ratio of 2:1 to obtain a reaction material, and react 200g Put the material in 400mL of xylene and react for 40min to obtain chloropropylated silica gel; take 40g of coniferous leaves and grind them in a mortar for 30min, then use 100mL of ...

example 2

[0031] Weigh 110mL of sodium silicate solution with a mass fraction of 40%, pour it into a three-necked flask with a stirrer, slowly adjust the pH to 7 with hydrochloric acid with a mass fraction of 10%, start the stirrer, and stir at a speed of 370r / min for 35min , microwave oscillating treatment for 4 minutes, set the microwave oscillating power to 750W to obtain nano-hydrosol, put the nano-hydrosol in an oven and heat up to 83°C, and dry for 3 hours to obtain nano-silica gel; weigh 200-220g nano-silica gel and place it in 420mL In the aqueous solution of methanesulfonic acid with a mass fraction of 40%, the temperature is controlled at 53°C and stirred for 25 minutes to obtain activated silica gel. The activated silica gel and chloropropyltrimethoxysilane are mixed in a mass ratio of 2:1 to obtain the reaction material. 230g of the reaction material was placed in 410mL of xylene and reacted for 42min to obtain chloropropylated silica gel; 43g of coniferous leaves were placed...

example 3

[0033] Weigh 120mL of sodium silicate solution with a mass fraction of 40%, pour it into a three-neck flask with a stirrer, slowly adjust the pH to 7 with hydrochloric acid with a mass fraction of 10%, start the stirrer, and stir at 400r / min for 40min , microwave oscillation treatment for 5 minutes, set the microwave oscillation power to 800W to obtain nano-hydrosol, put the nano-hydrosol in an oven and heat up to 85°C, and dry for 4 hours to obtain nano-silica gel; weigh 220g of nano-silica gel and put it in 450mL mass fraction In a 40% aqueous solution of methanesulfonic acid, control the temperature at 55°C, stir for 30 minutes to obtain activated silica gel, mix activated silica gel with chloropropyltrimethoxysilane in a mass ratio of 2:1 to obtain a reaction material, and react 250g Put the material in 420mL of xylene and react for 45min to obtain chloropropylated silica gel; take 50g of coniferous leaves and grind them in a mortar for 45min, then use 150mL of distilled wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com