Palladium/cuprous oxide reticular nano catalytic material and preparation and application thereof

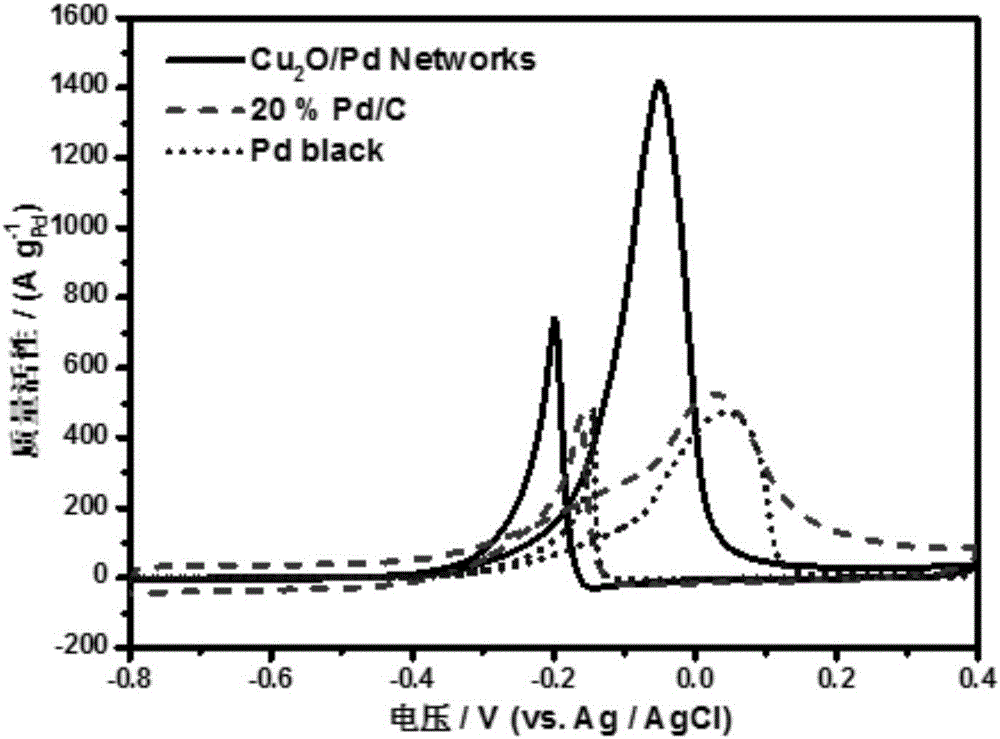

A nano-catalytic material, cuprous oxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that the performance of palladium-based catalysts cannot be greatly improved, and achieve good anti-poisoning ability As well as the effects of stability, convenience for delivery, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

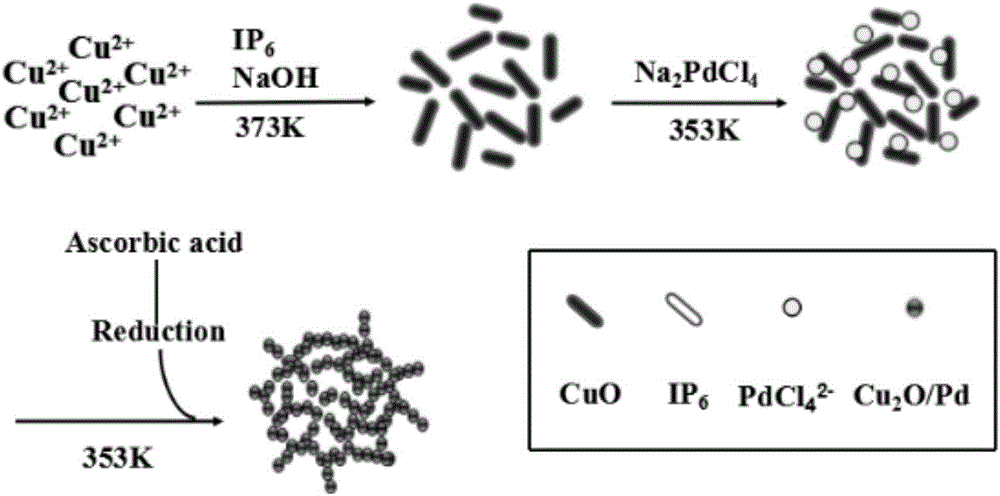

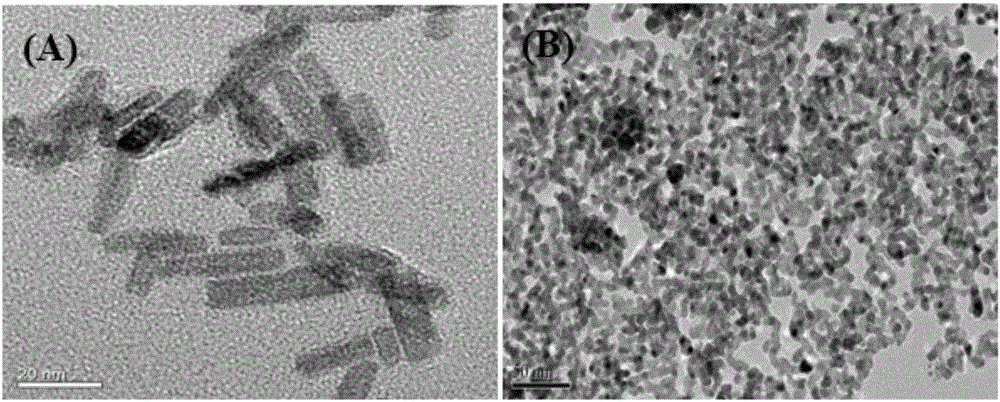

[0032] The preparation method of the palladium cuprous oxide nano-mesh anode material of highly active catalytic methanol comprises the following steps:

[0033] (1) Add 300μL of sodium phytate solution (1mM) into 10mL of deionized water, stir and heat to boiling, add 10mM copper chloride solution into the sodium phytate aqueous solution, keep the temperature at 90-100℃, and add 2M sodium hydroxide The solution was stirred continuously, reacted for 30 minutes, and added the same amount of sodium phytate as last time to prepare copper oxide nanorods protected by sodium phytate, centrifuged at 10000-20000rpm for 10min, and settled to 1mL to obtain oxidized Copper nanorod suspension (in this step, the mol ratio of sodium phytate, cupric chloride, alkali is 0.03:5:200);

[0034] (2) Disperse 15 μL of the copper oxide nanorod suspension in step (1) in 10 mL of deionized water, stir continuously and heat to a temperature of 70-100 ° C, add sodium tetrachloropalladate solution, and t...

Embodiment 2

[0041] A kind of preparation method of the electrode material that adopts palladium-cuprous oxide reticular nano catalytic material modification, comprises the following steps:

[0042] (1) Take the pre-prepared 0.5mM sodium phytate solution, add deionized water, stir and heat until boiling, keep the temperature at 90°C, then add 5mM copper chloride solution and 1M NaOH solution to it, and stir for 60min , adding sodium phytate again to obtain a suspension of copper oxide nanorods protected by sodium phytate, and the ratio of adding sodium phytate twice is 1:2.

[0043] (2) Take the copper oxide nanorod suspension in step (1), dilute with water, stir and heat to 100°C, then add 20mM sodium tetrachloropalladate solution and 0.2M ascorbic acid solution in turn to obtain palladium / oxide Cuprous nanoparticles, after centrifugal washing, are dispersed in water to obtain a palladium / cuprous oxide nanosuspension with a concentration of 0.2 mg / mL; the addition amount of each raw mater...

Embodiment 3

[0046] A kind of preparation method of the electrode material that adopts palladium-cuprous oxide reticular nano catalytic material modification, comprises the following steps:

[0047] (1) Take the pre-prepared 0.8mM sodium phytate solution, add deionized water, stir and heat until boiling, keep the temperature at 95°C, then add 8mM copper chloride solution and 1.6M NaOH solution to it, and stir to react After 20 minutes, sodium phytate was added again to obtain a suspension of copper oxide nanorods protected by sodium phytate, and the ratio of the amount of sodium phytate added twice was 1:1.5.

[0048] (2) Take the copper oxide nanorod suspension in step (1), dilute with water, stir and heat to 90°C, then add 15mM sodium tetrachloropalladate solution and 0.15M ascorbic acid solution in turn to obtain palladium / oxidized Cuprous nanoparticles, after centrifugal washing, are dispersed in water to obtain a palladium / cuprous oxide nanosuspension with a concentration of 0.1 mg / mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com