Paper diaper absorption core and preparation method thereof

A technology for absorbing cores and diapers, applied in absorbent pads, medical science, clothing, etc., can solve the problems of fluff pulp cores with lumps and faults, and achieve the effects of fast water absorption, improved liquid diffusion, and improved sleep quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

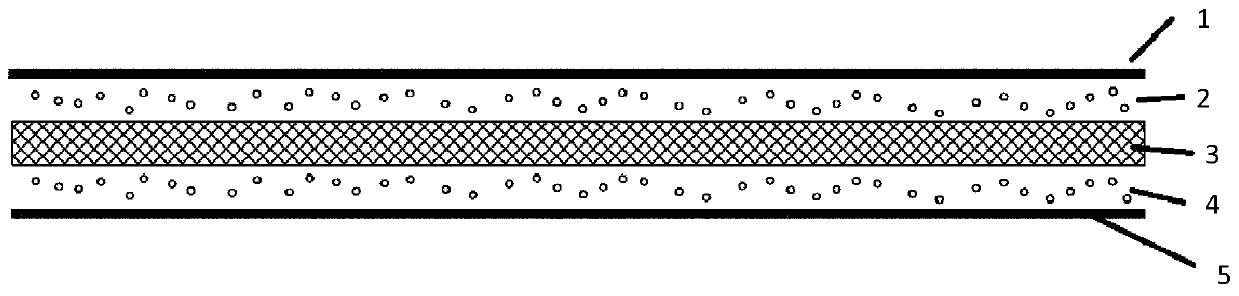

[0039] Such as figure 1 As shown in FIG. 1 , a schematic cross-sectional view of the main body of the absorbent core of a diaper provided by an embodiment of the present invention is shown. The main body comprises an upper covering layer 1 , a first polymer absorbing layer 2 , a fluffy cotton layer 3 , a second polymer absorbing layer 4 and a lower covering layer 5 stacked sequentially from top to bottom. The upper cladding layer 1 is 13gsm wet strength paper, and the lower cladding layer 5 is 30gsm direct lay spunlace non-woven fabric. The fluffy cotton is mixed with 4-denier ES fibers and 6-denier PET fibers and bonded by hot air to obtain a fluffy nonwoven fabric of 35 gsm.

Embodiment 2

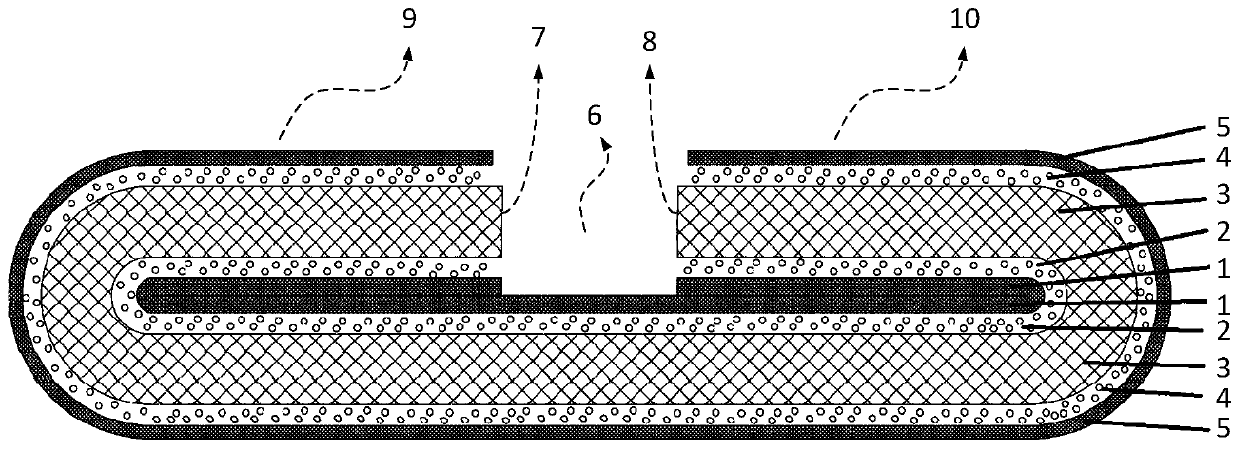

[0041] Such as figure 2 As shown, a schematic cross-sectional view of the absorbent core of a diaper provided by an embodiment of the present invention is shown. The absorbent core can be seen as figure 1 The two side ends 7, 8 of the main body in the body are bent to the upper covering layer 1, and after the bending, the two side ends 7, 8 face each other at intervals, so that grooves 6 are formed on the upper surface of the absorbent core. The left side of the groove 6 is a left bending part 9 , and the right side is a right bending part 10 . The groove 6 is arranged in the middle of the upper surface of the absorbent core, so that the left bending part 9 and the right bending part 10 are symmetrical to the groove 6 . The groove 6 is linear in longitudinal direction, rectangular in cross section and 15mm in width.

Embodiment 3

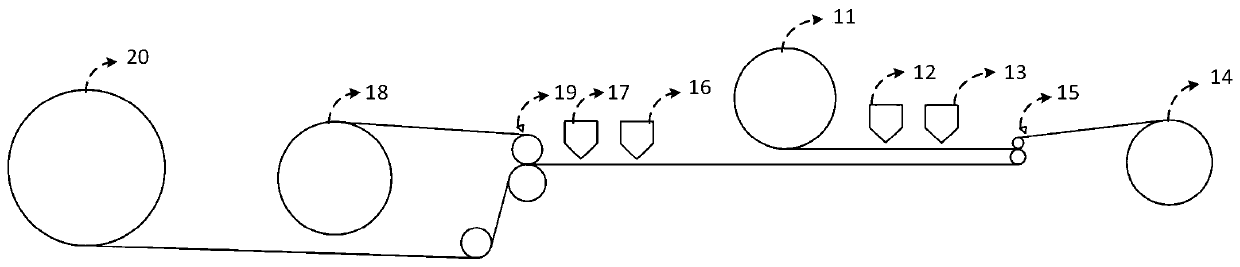

[0043] Such as image 3 As shown in FIG. 1 , it shows a schematic diagram of the production line of the method for preparing the absorbent core of a diaper provided by an embodiment of the present invention. The pipeline includes the following steps:

[0044] S1. Fluffy cotton unwinding process: After the finished fluffy cotton is unrolled 11, it is continuously conveyed to the direction of the first particle hopper 12 and the second particle hopper 13 of the second polymer absorbent material through an auxiliary device; wherein the first particle hopper 12 Contain superabsorbent resin (SAP) particles of different size gradations in the second particle hopper 13;

[0045] S2. The second polymer absorbent material blanking process: the hoppers 12 and 13 evenly spread the second polymer absorbent material graded in different sizes on the fluffy cotton transported here through the S1 process;

[0046] S3. Lamination process of the lower cladding layer: Unwind the finished roll ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com