Process for production of water-absorbing resin particles, water-absorbing resin particles, water-stopping material, and absorbent article

A technology of resin particles and a manufacturing method is applied in the fields of the manufacture of water-absorbent resin particles, water-absorbent resin particles, water-stopping materials and absorbent articles, and can solve the problem of not obtaining water-absorbent resin particles and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

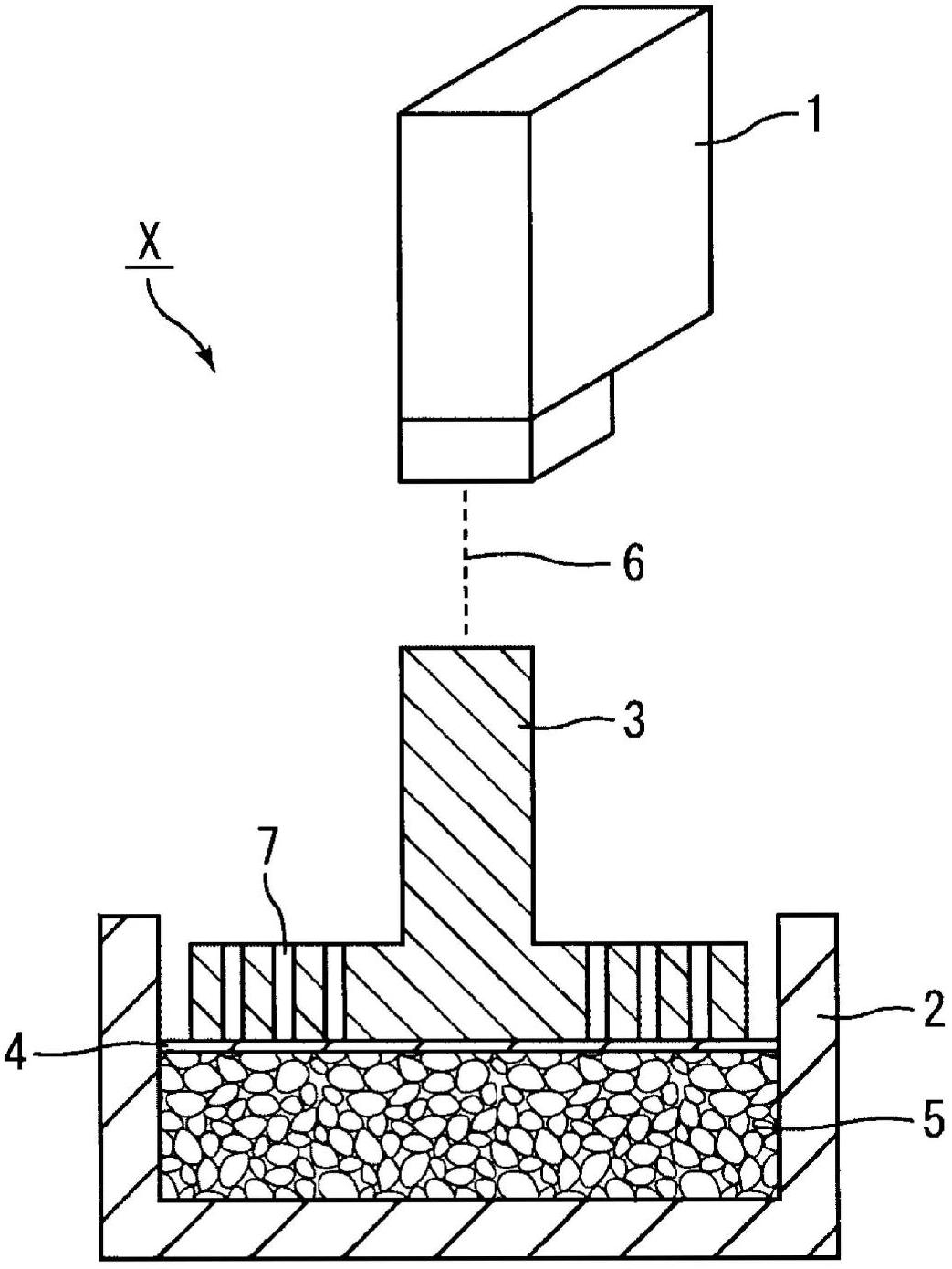

Image

Examples

Embodiment 1

[0104] Prepare a round-bottom cylindrical type detachable flask with an inner diameter of 100 mm, which has a reflux cooler, a dropping funnel, a nitrogen gas introduction tube, a stirring paddle (coated with a fluororesin on the surface) as a stirrer, and the stirring paddle is divided into The two sections have 4 oblique-bladed flat paddles with a paddle diameter of 50mm. 550 mL of n-heptane was added to the flask, and 0.84 g of sorbitan monolaurate (manufactured by NOF Corporation, Nonion LP-20R) of HLB8.6 was added as a surfactant, and the temperature was raised to 50° C. to make the surfactant After dissolving, cool to 40°C.

[0105] On the other hand, 70 g (0.783 mol) of an 80.5 mass % acrylic acid aqueous solution was added to a 500 mL Erlenmeyer flask, and 112.3 g of a 20.9 mass % sodium hydroxide aqueous solution was added dropwise while ice-cooling to neutralize 75 mol %. 0.084 g of potassium persulfate was added and dissolved to prepare an aqueous monomer solution....

Embodiment 2~4

[0110] In Example 1, the amount of water discharged out of the system in one drying step was 74.9 g, 64.5 g, and 81.8 g, respectively, and the amount of 2% aqueous solution of ethylene glycol diglycidyl ether was 1.05 g (0.00012 mol) , 0.7g (0.00008 mol), 1.75g (0.0002 mol), so that the moisture content (to polymer solid content) is 57 mass%, 71 mass%, 48 mass% respectively, except that, carry out the same procedure as in Example 1 By operation, 72.8 g, 72.7 g, and 73.1 g of granular water-absorbent resin particles were obtained, respectively.

Embodiment 5

[0112] In Example 1, the amount of water discharged out of the system in one drying step was 81.8 g, and 2.47 g (0.00019 mol) of a 2% aqueous solution of polyglycerol glycidyl ether was added without adding ethylene glycol diglycidyl ether, so that Except that the water content (with respect to the polymer solid content) was 49% by mass, the same operation as in Example 1 was carried out to obtain 72.4 g of granular water-absorbent resin particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hygroscopic ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com