Starch hemostatic microsphere and preparation method thereof

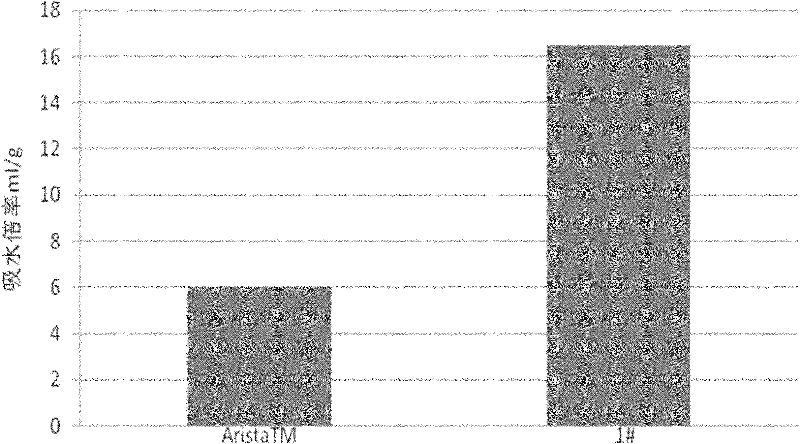

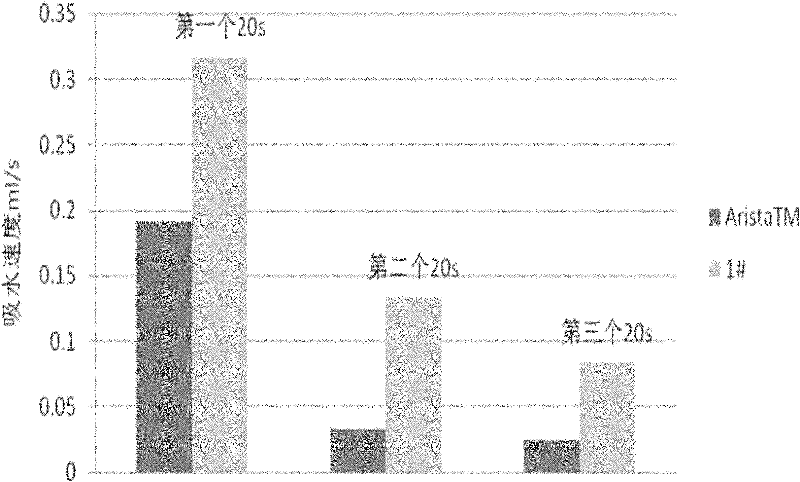

A technology of starch and microspheres, applied in medical science, bandages, absorbent pads, etc., can solve the problems of poor hemostatic effect of large blood vessels, blood-borne disease infection, insufficient water absorption, etc., and achieve improved hemostatic effect and biocompatibility Good performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

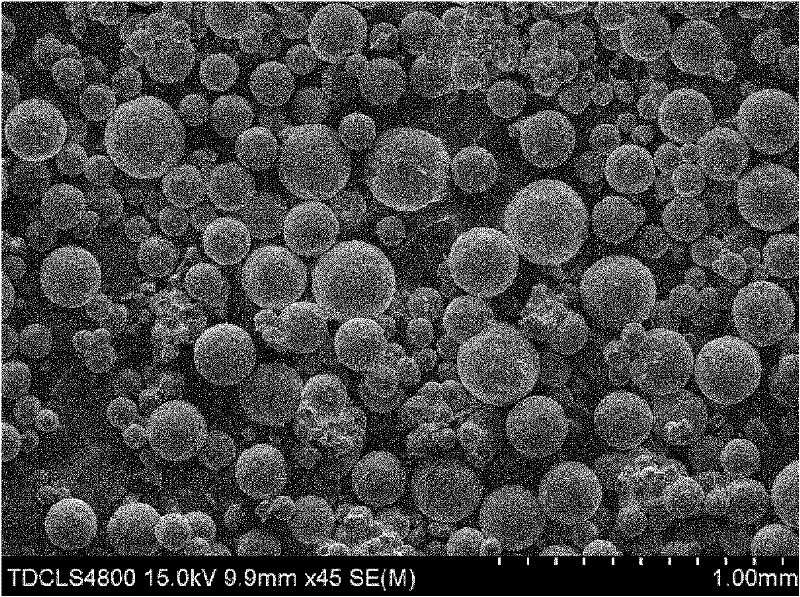

Embodiment 1

[0048] A preparation method of starch hemostatic microspheres, the steps are as follows:

[0049] (1) Preparation of starch alkaline solution: weigh 1g of pea starch, 2g of potato starch, 2g of cornstarch, 30-100ml of distilled water, dissolve the starch in distilled water, adjust the pH to 8.5-10.5 with 1mol / L NaOH, stir for 2 hours, and stir The speed is 400-600r / min, and the activated starch alkaline solution is obtained;

[0050] (2) Preparation of vegetable oil-starch mixed solution: after mixing 1-3g of surfactant span600 and 200-1000ml of vegetable oil, stir in a water bath at 60-80°C for 0.5-2h, and then add it to the starch lye in step (1), Stir and mix for 2 to 4 hours to obtain a vegetable oil-starch mixed solution;

[0051] (3) Cross-linking treatment: dropwise add 1-5 ml of cross-linking agent epichlorohydrin to the vegetable oil-starch mixed solution obtained in step (2), and the time for dropping is 1-2 hours to form a reaction system, react for 4-6 hours, The...

Embodiment 2

[0054] A preparation method of starch hemostatic microspheres, the steps are as follows:

[0055] (1) Preparation of starch alkaline solution: weigh 1g of mung bean starch, 2.5g of tapioca starch, 3g of cornstarch, 30-100ml of distilled water, dissolve the starch in distilled water, adjust the pH to 8.5-10.5 with 1mol / L NaOH, stir for 2h, The stirring speed is 400-600r / min, and the activated starch alkaline solution is obtained;

[0056] (2) Preparation of vegetable oil-starch mixed solution: after mixing 1-3g of surfactant span600 and 200-1000ml of vegetable oil, stir in a water bath at 60-80°C for 0.5-2h, and then add it to the starch lye in step (1), Stir and mix for 2 to 4 hours to obtain a vegetable oil-starch mixed solution;

[0057] (3) Cross-linking treatment: dropwise add 1-5 ml of cross-linking agent epichlorohydrin to the vegetable oil-starch mixed solution obtained in step (2), and the time for dropping is 1-2 hours to form a reaction system, react for 4-6 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com