6XXX aluminum alloy suitable for automobile body and preparation process of automobile body plate

A technology for automobile bodies and aluminum alloys, which is applied in the preparation process of 6XXX aluminum alloys and body panels, and in the field of 6XXX series aluminum alloys, which can solve the problems of the safety performance of the body panels, the impact of dent resistance, and low strength, and achieve a reasonable microstructure , improve the elongation rate, and ensure the rationality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

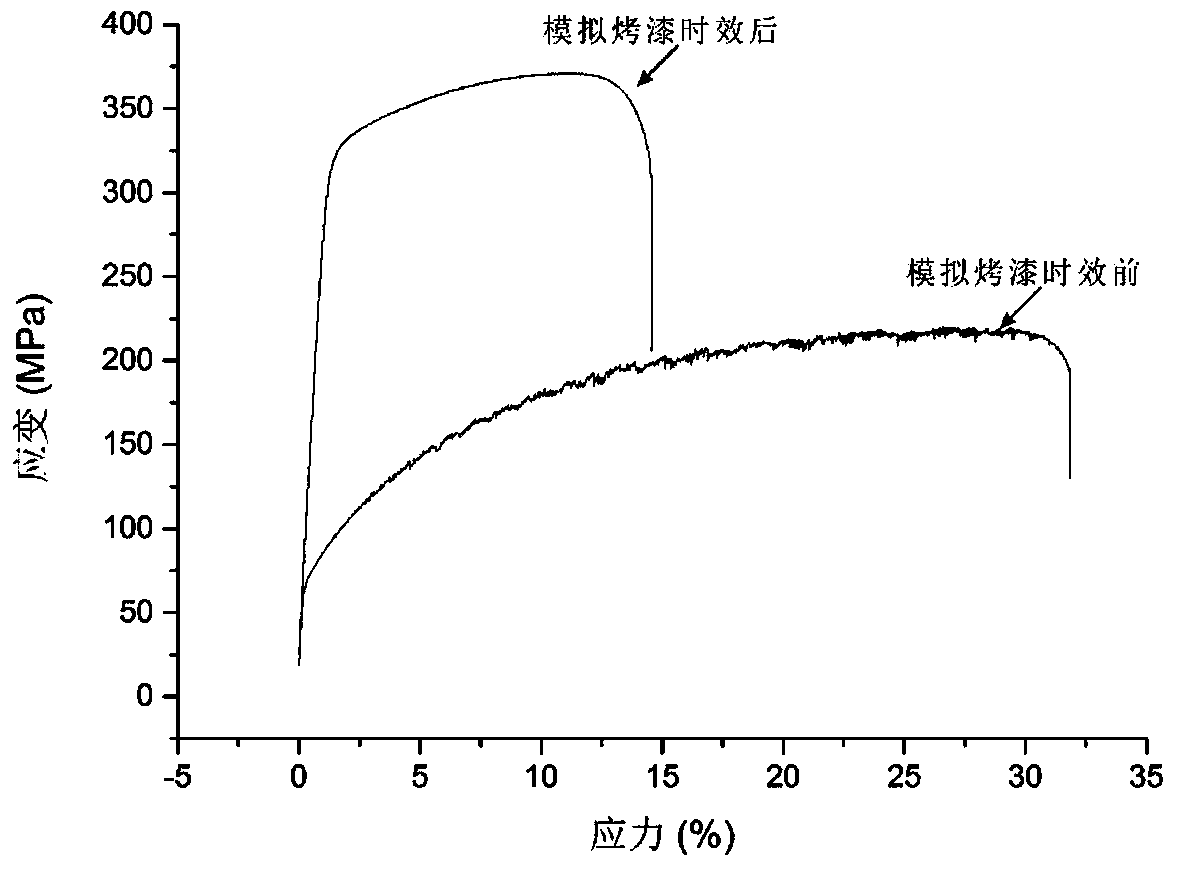

[0076] The composition is 1.15% magnesium, 0.88% silicon, 0.5% manganese, 0.5% copper, 0.2% iron, and the rest is Al and unavoidable impurities. After the aluminum alloy ingot is homogenized by the above process, hot rolled and cold rolled To obtain a plate with a thickness of 1mm, heat the aluminum alloy plate at 545°C for 35 minutes, and conduct a tensile test immediately after water cooling and quenching; the other group simulates the aging of the paint within 30 to 60 seconds after water cooling and quenching, and heats it at about 185°C for 30 to 35 minutes Then the stretching test was carried out.

[0077] Table 1 Example 1 Tensile test before and after baking paint

[0078]

Embodiment 2

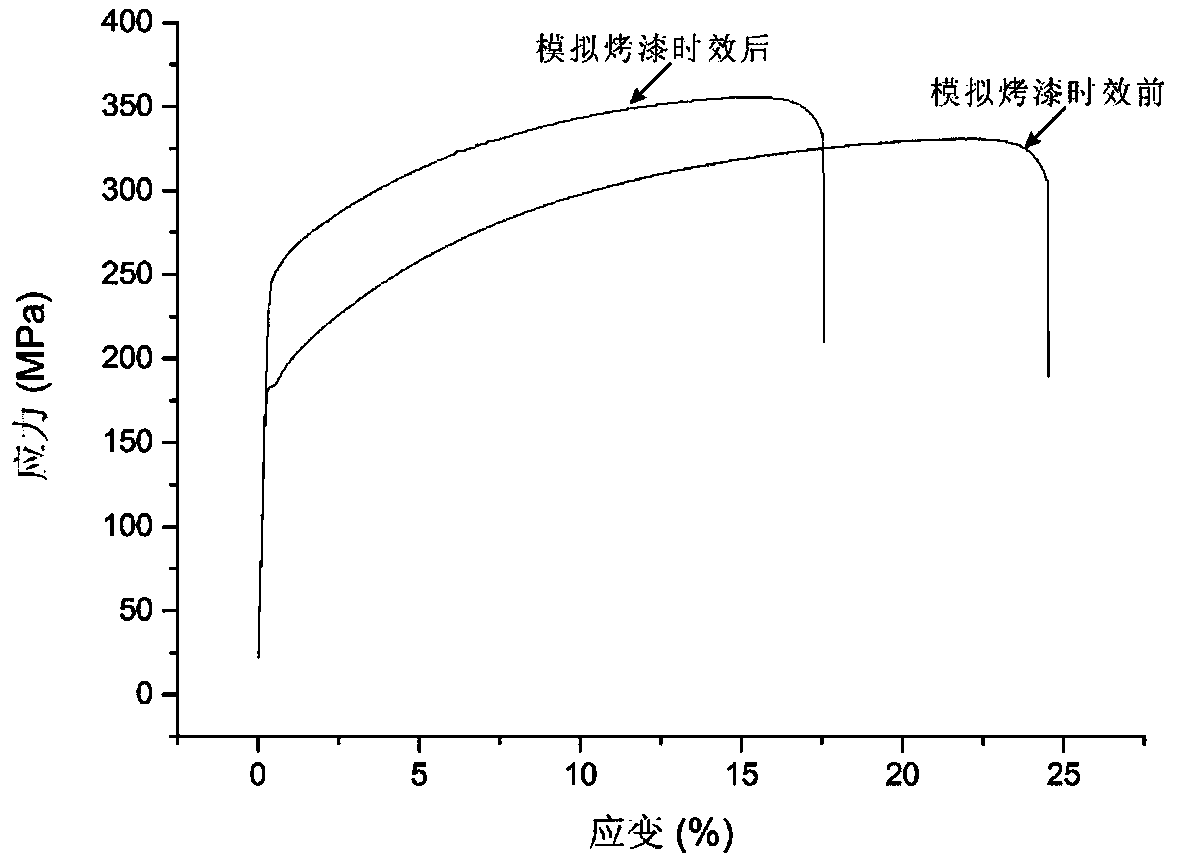

[0080]The composition is 1.15% magnesium, 0.88% silicon, 0.5% manganese, 0.5% copper, 0.2% iron, and the rest is Al and unavoidable impurities. After the aluminum alloy ingot is homogenized by the above process, hot rolling and cold rolling To obtain a plate with a thickness of 1mm, heat the aluminum alloy plate at 545°C for 35 minutes, and then place it naturally for 15 days after water cooling and quenching to simulate the aging of the paint.

[0081] Table 2 Example 2 Tensile test before and after baking paint

[0082]

Embodiment 3

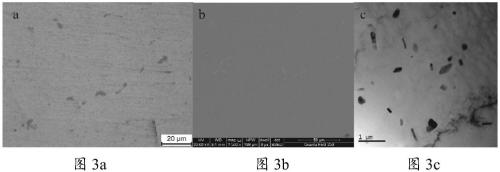

[0084] The composition is 1.15% magnesium, 0.88% silicon, 0.5% manganese, 0.5% copper, 0.2% iron, and the rest is Al and unavoidable impurities. After the alloy casting is completed, the aluminum alloy ingot is passed through the process described in the article After homogenization, hot rolling and cold rolling, a plate with a thickness of 1mm is obtained. The aluminum alloy plate is kept at 545°C for 35 minutes. Microhardness test, the results are shown in Table 3, and the solid solution state of the plate and the microstructure of the secondary artificial aging sample are observed, see Figures 3-7.

[0085] Table 3 Microhardness under secondary artificial aging state

[0086]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com