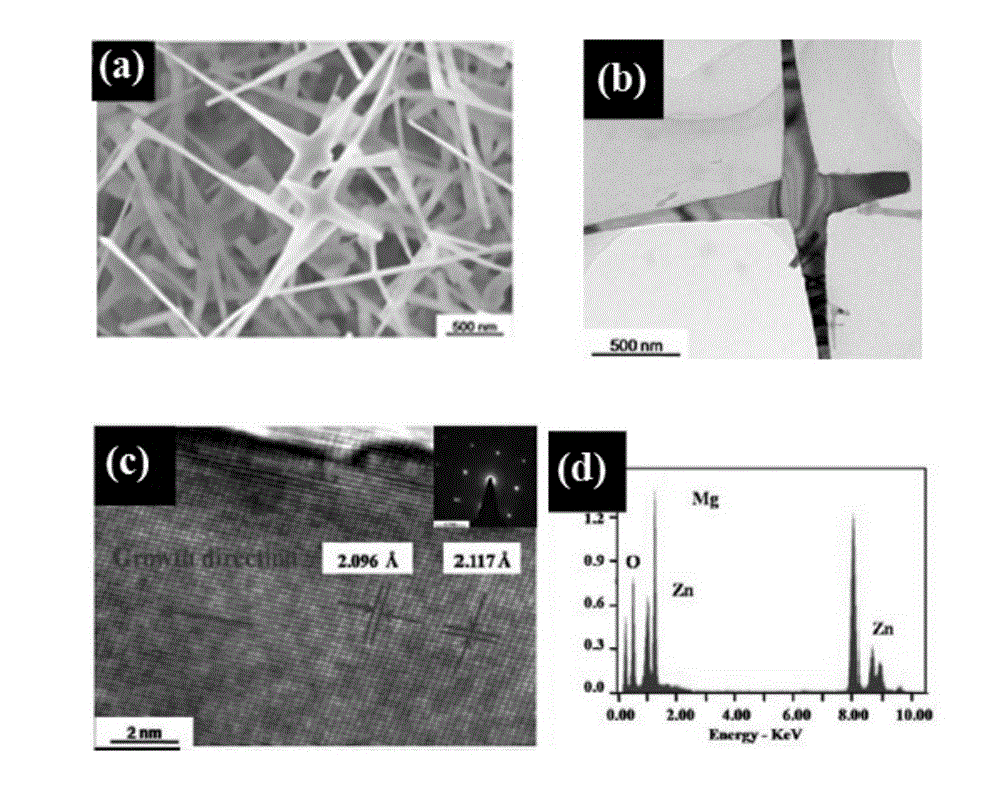

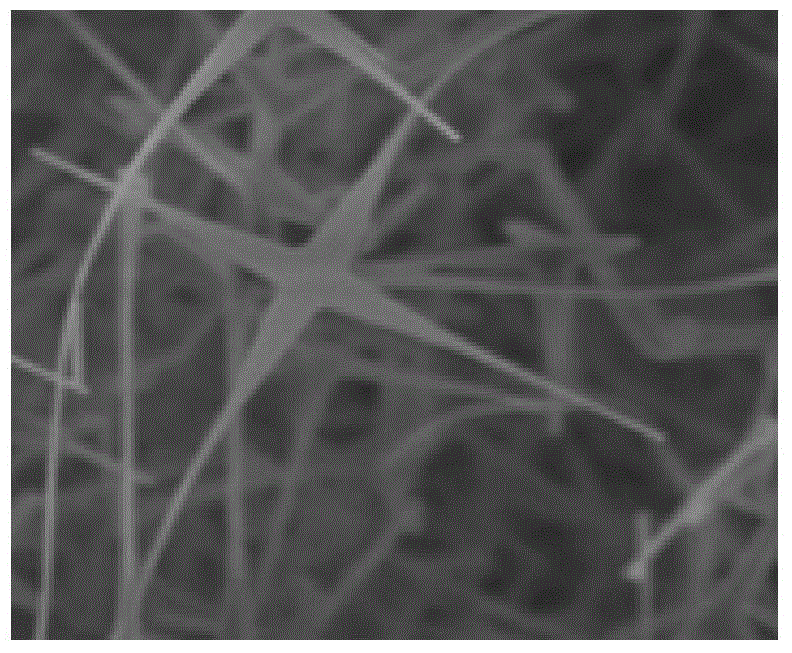

Water chestnut type high-magnesium-content Zn<1-x>Mg<x>O nanometer structure and preparation method thereof

A technology of zn1-xmgxo and nanostructures, which is applied in the field of nano-functional material preparation, can solve the problems of undisclosed ZnMgO alloy nanowire nanostructure content, etc., and achieve the effect of simple equipment control, convenient operation, and high degree of freedom in growth parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

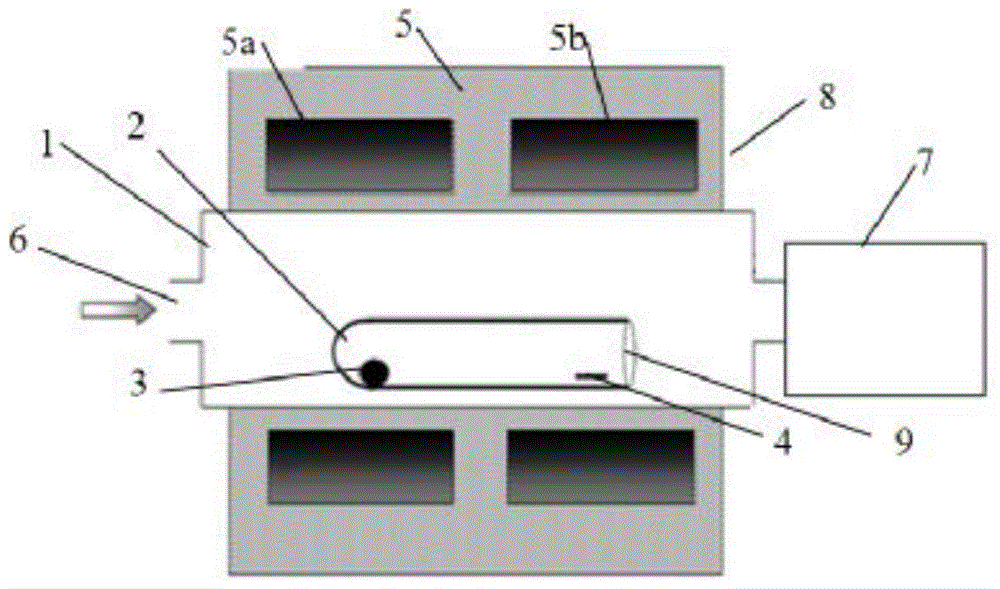

[0029] Growing equipment such as figure 1 In the shown dual temperature zone tube furnace, the purity of pure zinc powder and pure magnesium powder are 99.999% and 99% respectively, and the substrate is Si(100) sheet. Concrete preparation steps are as follows:

[0030] (1) Mix and grind pure zinc powder and pure magnesium powder in a mass ratio of 5:1. After mixing fully, take 1g of the mixture and pour it into the quartz tube 2 as the source material 3 of the reaction, and then put the quartz tube containing the mixture The tube 2 is put into the bottom of a tubular reaction chamber 1 with a diameter of 2 cm, a length of 25 cm, and an opening at one end, and then the cleaned substrate 4 is placed in the quartz tube 2 near the opening 9 of the quartz tube;

[0031] (2) Place the tubular reaction chamber 1 carrying the quartz tube 2 in the tube furnace 8, adjust the position so that the source material 3 and the substrate 4 are respectively located at the center of the respect...

Embodiment 2

[0037] Growing equipment such as figure 1 In the shown dual temperature zone tube furnace, the purity of pure zinc powder and pure magnesium powder are 99.999% and 99% respectively, and the substrate is Si(100) sheet. Concrete preparation steps are as follows:

[0038] (1) Mix and grind pure zinc powder and pure magnesium powder according to the mass ratio of 4:1. After mixing fully, take 1g of the mixture and pour it into the quartz tube 2 as the source material 3 of the reaction, and then put the quartz tube loaded with the mixture The tube 2 is put into the bottom of a tubular reaction chamber 1 with a diameter of 2 cm, a length of 25 cm, and an opening at one end, and then the cleaned substrate 4 is placed in the quartz tube 2 near the opening 9 of the quartz tube;

[0039] (2) Place the tubular reaction chamber 1 carrying the quartz tube 2 in the tube furnace 8, adjust the position so that the source material 3 and the substrate 4 are respectively located at the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com