Mg-Ni-(Gd,Nd) bulk amorphous alloy and preparation thereof

A technology of amorphous alloy and bulk, applied in the field of magnesium alloy material and its preparation, Mg-Ni-based bulk amorphous alloy and its preparation, can solve the problem of low formation ability of Mg-Ni-RE based amorphous, resistance Poor corrosion ability, poor plasticity of amorphous alloys, etc., to achieve high amorphous formation ability, good corrosion resistance, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

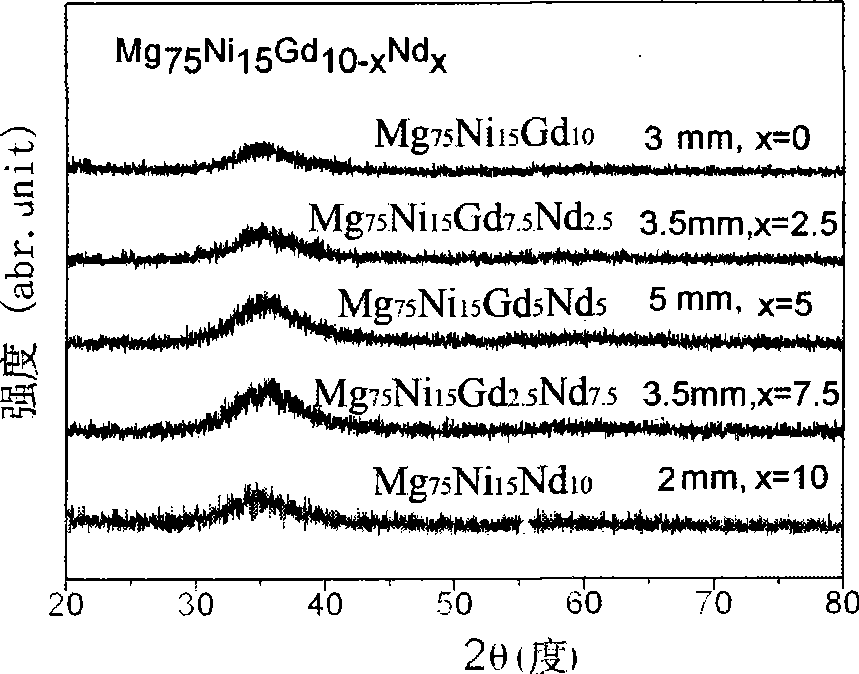

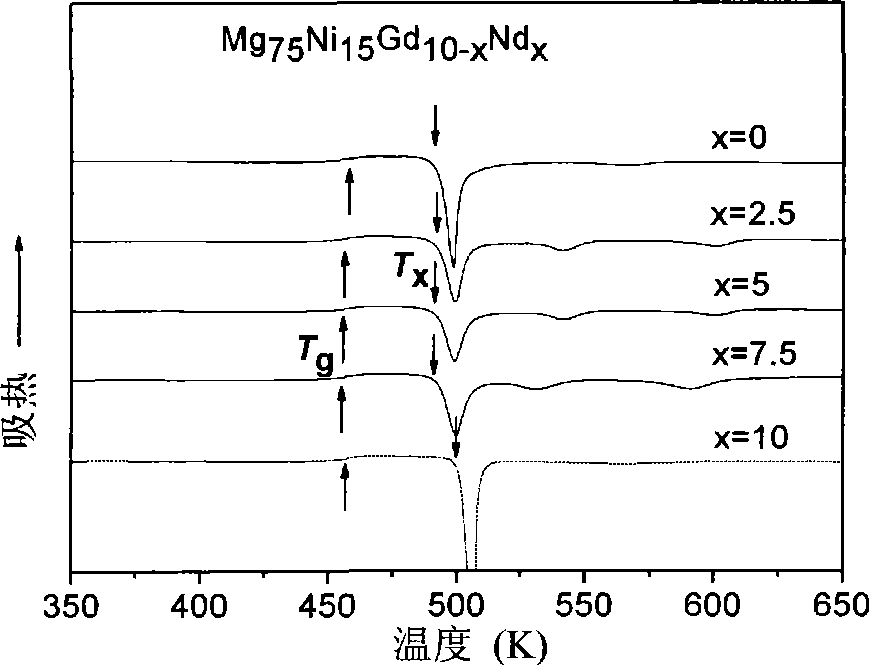

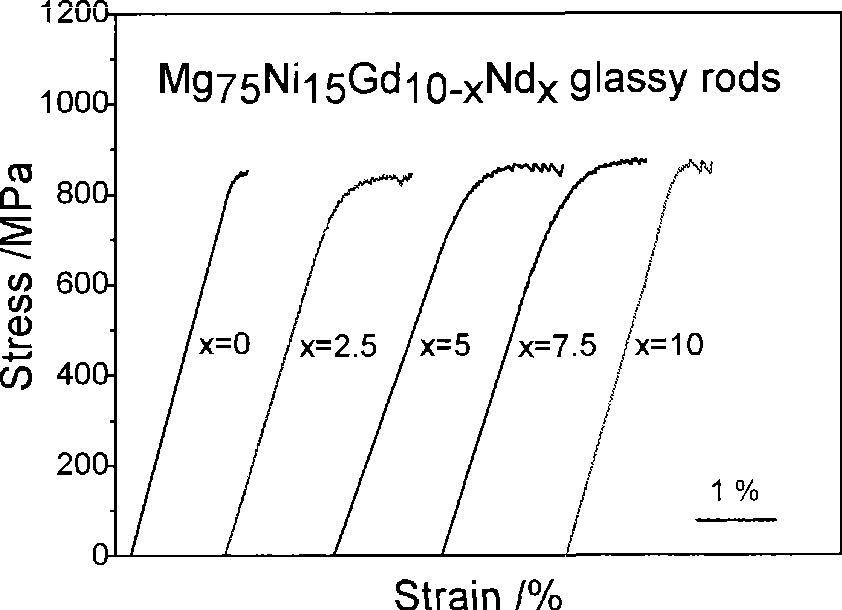

[0025] Embodiment 1, the Mg of diameter 5mm 75 Ni 15 Gd 5 Nd 5 bulk amorphous alloy

[0026] Step 1, according to Mg 75 Ni 15 Gd 5 Nd 5 Raw materials of magnesium, nickel and rare earth gadolinium and neodymium are prepared: Mg, Ni, Gd and Nd metals with a purity greater than 99% and a molar ratio of 75:15:5:5 are used.

[0027] Step 2, vacuumize the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. The arc melting of titanium absorbs oxygen in the atmosphere, and then the raw materials of the first step, gadolinium and neodymium, are repeatedly smelted and purified four times in the electric arc furnace.

[0028] Step 3, vacuumize the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. Arc melting titanium absorbs oxygen in the atmosphere, then mix and melt the gadolinium and neodymium obtained in the seco...

Embodiment 2

[0034] Embodiment 2, the Mg of diameter 3.5mm 75 Ni 15 Gd 7.5 Nd 2.5 bulk amorphous alloy

[0035] Step 1: According to Mg 75 Ni 15 Gd 5 Nd 5Prepare magnesium, nickel and rare earth gadolinium and neodymium raw materials: Mg, Ni, Gd and Nd metals with a purity greater than 99% and a molar ratio of 75:15:7.5:2.5 are used.

[0036] Step 2: Vacuum the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. The arc melting of titanium absorbs oxygen in the atmosphere, and then the raw materials of the first step, gadolinium and neodymium, are repeatedly smelted and purified four times in the electric arc furnace.

[0037] Step 3, vacuumize the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. Arc melting titanium absorbs oxygen in the atmosphere, then mix and melt the gadolinium and neodymium obtained in the second...

Embodiment 3

[0043] Embodiment 3, the Mg of diameter 3.5mm 75 Ni 15 Gd 2.5 Nd 7.5 bulk amorphous alloy

[0044] Step 1: According to Mg 75 Ni 15 Gd 5 Nd 5 Prepare magnesium, nickel and rare earth gadolinium and neodymium raw materials: Mg, Ni, Gd and Nd metals with a purity greater than 99% and a molar ratio of 75:15:2.5:7.5 are used.

[0045] Step 2: Vacuum the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. The arc melting of titanium absorbs oxygen in the atmosphere, and then the raw materials of the first step, gadolinium and neodymium, are repeatedly smelted and purified four times in the electric arc furnace.

[0046] Step 3, vacuumize the electric arc furnace to 3×10 -3 Pa, filled with a pure argon atmosphere with a purity greater than 99.99% to a pressure of 0.5 atm. Arc melting titanium absorbs oxygen in the atmosphere, then mix and melt the gadolinium and neodymium obtained in the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com