Microbial fertilizer producing by using agricultural wastes and preparation thereof

A technology for microbial fertilizers and agricultural wastes, applied in the preparation of organic fertilizers, agriculture, organic fertilizers, etc., to promote the absorption and utilization of soil available phosphorus by plants, reduce chemical fertilizer residues and pollution, and improve safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

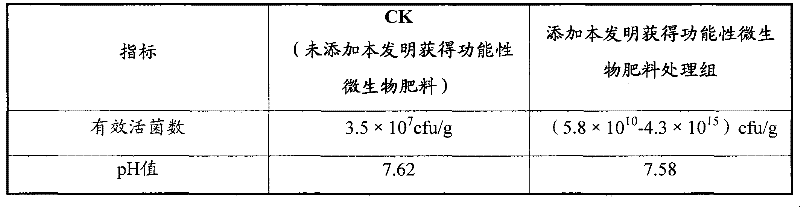

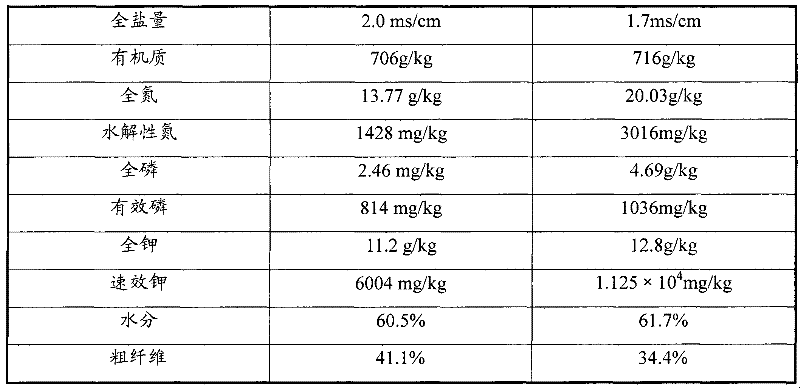

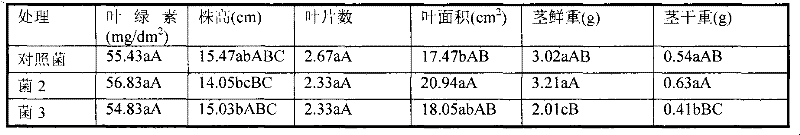

Embodiment 1

[0024] Mix 20% oily bean dregs, 60% crop straw, and 15% livestock and poultry manure to obtain the main ingredient after crushing, and adjust the water content to 60%; add a compound fermentation agent at 150g / T to pile up the cone shape, and seal it with yellow mud for external use , sealed and covered with a plastic film outside, stacked and fermented under natural conditions, the composite starter is composed of Bacillus subtilis, Bacillus licheniformis, Trichoderma harzianum and Trichoderma viride ) in terms of mass ratio (W / W) according to 1.5: 1: 1: 2.5: 4, stacked and fermented for 30 days, and turned 2-3 times during the period; the auxiliary materials 5% mushroom slag, 6% rice husk ash and the above The main ingredients prepared by fermentation are mixed evenly, and then add arbuscular mycorrhizal fungi at 600 / T. The arbuscular mycorrhizal fungi are composed of Glomus etunicatum, Glomus mosseae and surface ball Glomus versiforme (Glomus versiforme) was assembled accor...

Embodiment 2

[0026] Mix 40% oily bean dregs, 40% crop straw, and 15% livestock and poultry manure to obtain the main ingredient after crushing, and adjust the water content to 65%; add a compound fermentation agent at 200g / T to pile up the cone shape, and yellow mud for external use Seal the outside with a plastic film seal cover, pile up and ferment and decompose under natural conditions. The composite starter is composed of Bacillus subtilis, Bacillus licheniformis, Trichoderma harzianum and Trichoderma viride. viride) is assembled according to the mass ratio (W / W) of 1.5:1:1:2.5:4, stacked for fermentation and decomposing for 30 days, and turned 2-3 times during the period; add 10% mushroom slag, 10% rice husk ash and The main ingredients prepared by the above fermentation are mixed evenly, and then add arbuscular mycorrhizal fungi at 1000g / T. Glomus versiforme (Glomus versiforme) was assembled according to 3:3:2 in terms of mass ratio (W / W), and passed through a 3mm sieve to prepare mi...

Embodiment 3

[0028] Mix 30% oily bean dregs, 50% crop straw, and 15% livestock and poultry manure to obtain the main ingredient after crushing, and adjust the water content to 60-65%; The mud is sealed, and the outside is covered with a plastic film seal, and it is stacked and fermented under natural conditions. The composite starter is composed of Bacillus subtilis, Bacillus licheniformis, Trichoderma harzianum and Trichoderma viride ( Trichoderma viride) is assembled according to the mass ratio (W / W) of 1.5:1:1:2.5:4, stacked and fermented for 33 days, and turned 2-3 times during the period; the auxiliary materials are 8% mushroom dregs, 8% rice husk ash Mix evenly with the main ingredients prepared by the above fermentation, and then add arbuscular mycorrhizal fungi at 800g / T, which consists of Glomus etunicatum, Glomus mosseae and Glomus mosseae Glomus versiforme (Glomus versiforme) was assembled in a mass ratio (W / W) of 3:3:2, passed through a 3mm sieve to prepare microbial fertilizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com