Vertical non-stirred organic waste dry-type anaerobic digestion processing equipment and method

A technology for digestion and treatment of organic waste, applied in the field of solid waste treatment technology and biomass energy, can solve the problems that affect the normal operation of the digestive system, acidification of fermentation materials, scum and sedimentation, etc., to overcome homogeneous mixing Difficulty, easy maintenance and management, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

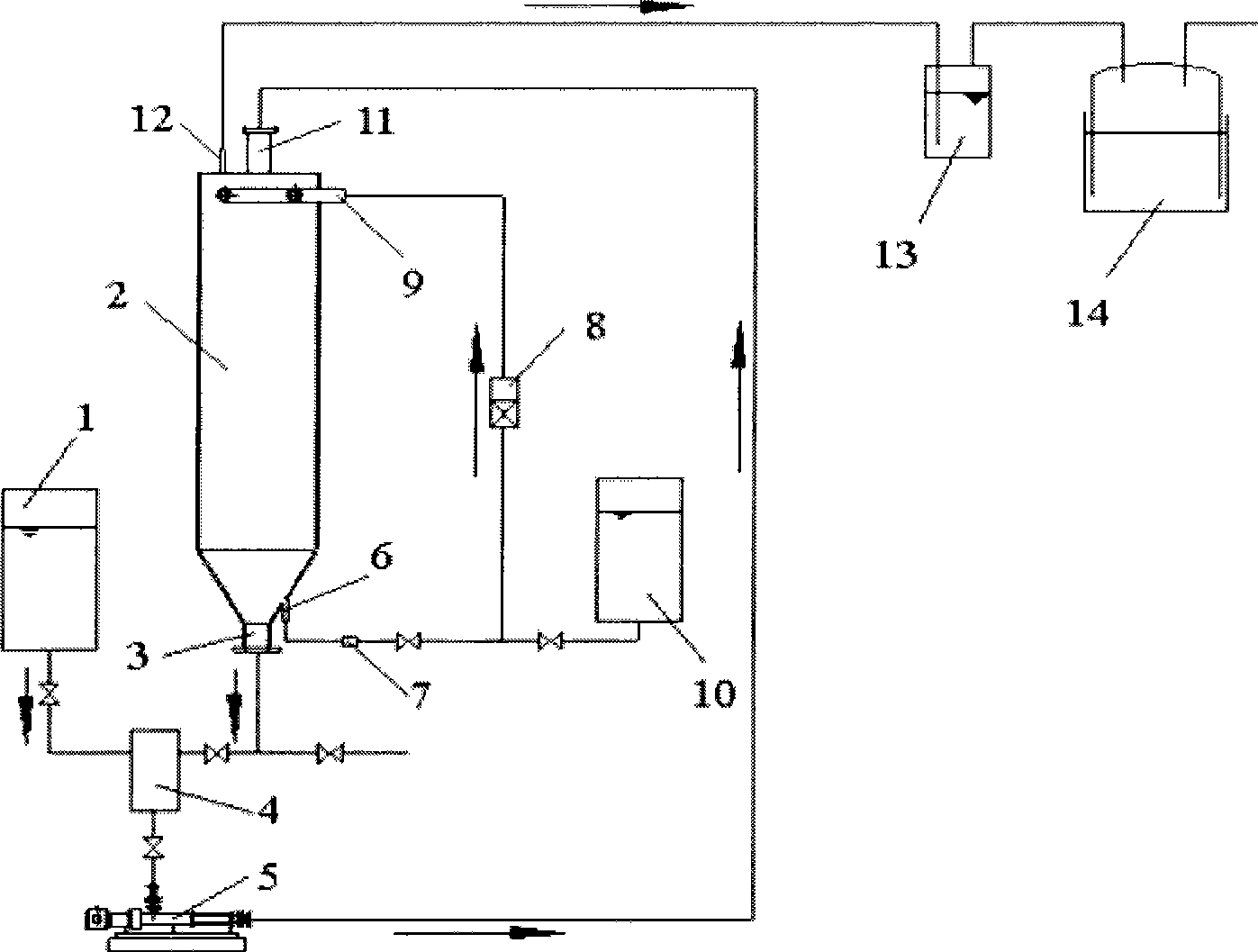

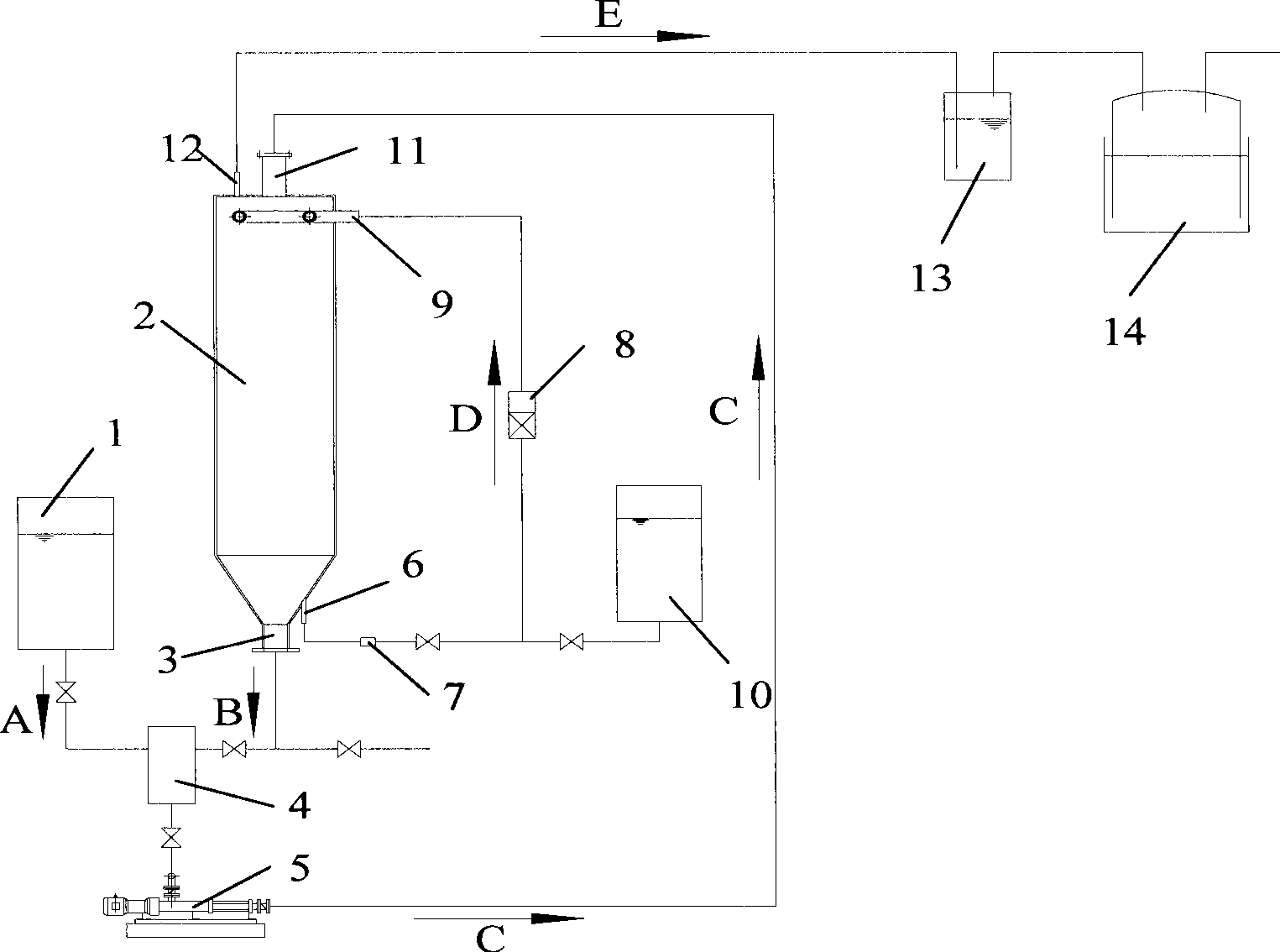

[0030] This embodiment provides a vertical non-stirring organic waste dry-type anaerobic digestion treatment equipment, the equipment structure is as follows figure 1 As shown, it specifically includes: feed storage tank 1, vertical digestion tank 2, discharge port 3, feed and inoculum mixing tank 4, material delivery pump 5, biogas slurry discharge pipe 6, biogas slurry pH online monitor 7. Biogas slurry return pump 8, biogas slurry spray device 9, lye storage tank 10, feed port 11 and gas outlet 12;

[0031] Wherein, the tank body of the vertical digestion tank is composed of an upper cylinder and a lower cone, the height-to-diameter ratio of the upper cylinder and the lower cone is 2-3:1, and the apex angle of the lower cone is 60±5°. There is a feed inlet and an air outlet on the top, and a discharge outlet on the bottom of the digestive tank; the tank body with this structure can save the need to install a stirring device, so that the materials in the tank are in the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com