Combined column formed by embedding round steel tubes filled with recycled concrete in multiple-cavity steel pipe filled with concrete and provided with batten plates

A technology of recycled concrete and steel pipe concrete, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of low strength, low elastic modulus, and poor durability of recycled concrete, and achieve improved bearing capacity, increased ductility coefficient, and improved seismic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

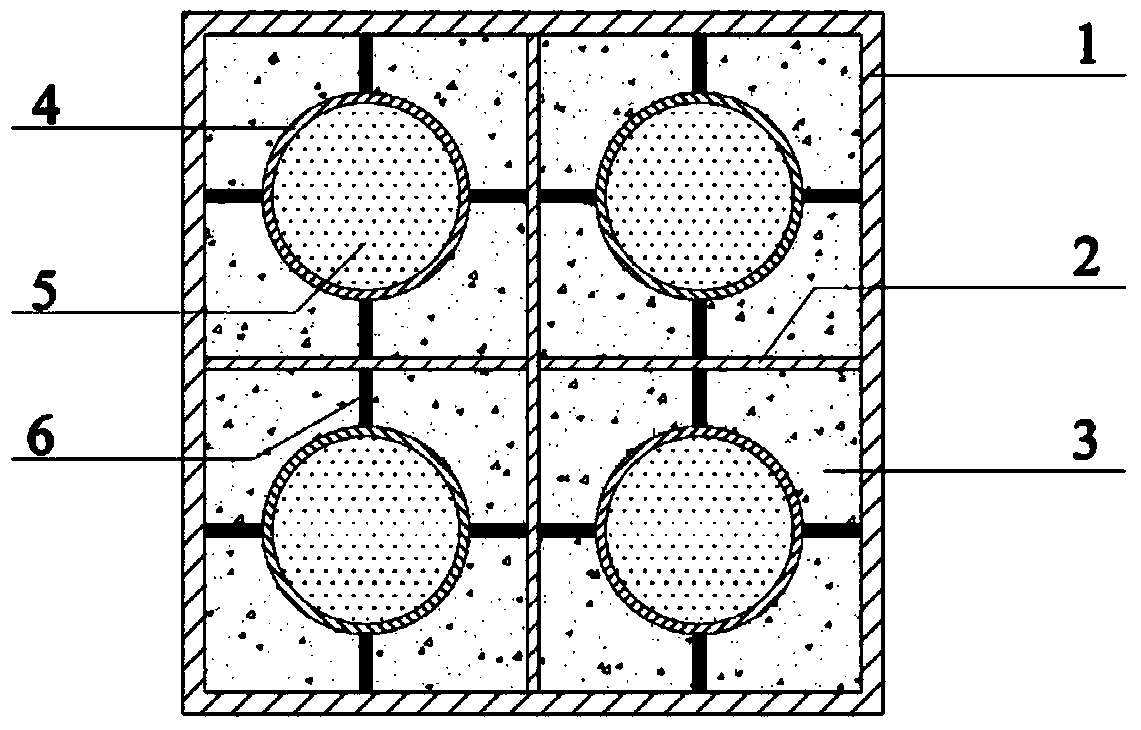

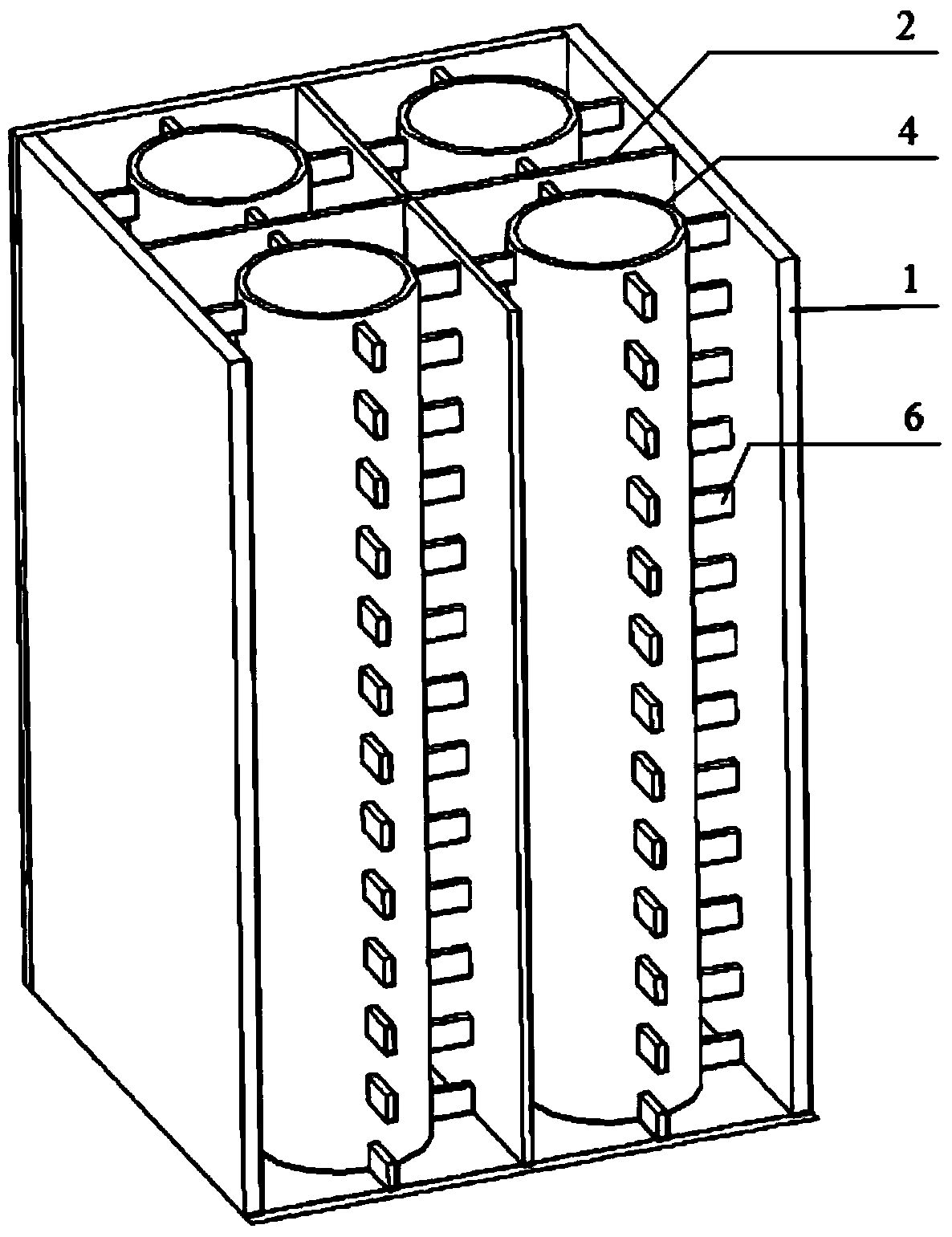

[0033] Such as figure 1 As shown, the multi-cavity steel pipe concrete embedded circular steel pipe recycled concrete composite column with decorative plate includes polygonal steel pipe 1, inner partition plate 2, ordinary concrete 3, round steel pipe 4, recycled concrete 5, and decorative plate 6; the polygonal steel pipe 1 Divided into multiple cavities by the inner partition 2, each cavity is provided with a round steel pipe 4, and the round steel pipe 4 is connected with each inner wall of the cavity with a panel 6; the round steel pipe 4 is filled with recycled concrete 5; each Ordinary concrete 3 is filled outside the circular steel pipe 4 inside the cavity. The multi-cavity steel pipe concrete embedded circular steel pipe recycled concrete composite column is formed by the ordinary multi-cavity steel pipe concrete built-in circular steel pipe recycled concrete.

[0034] The inner partitions are generally arranged in the direction of the two main axes of the polygonal ...

Embodiment 2

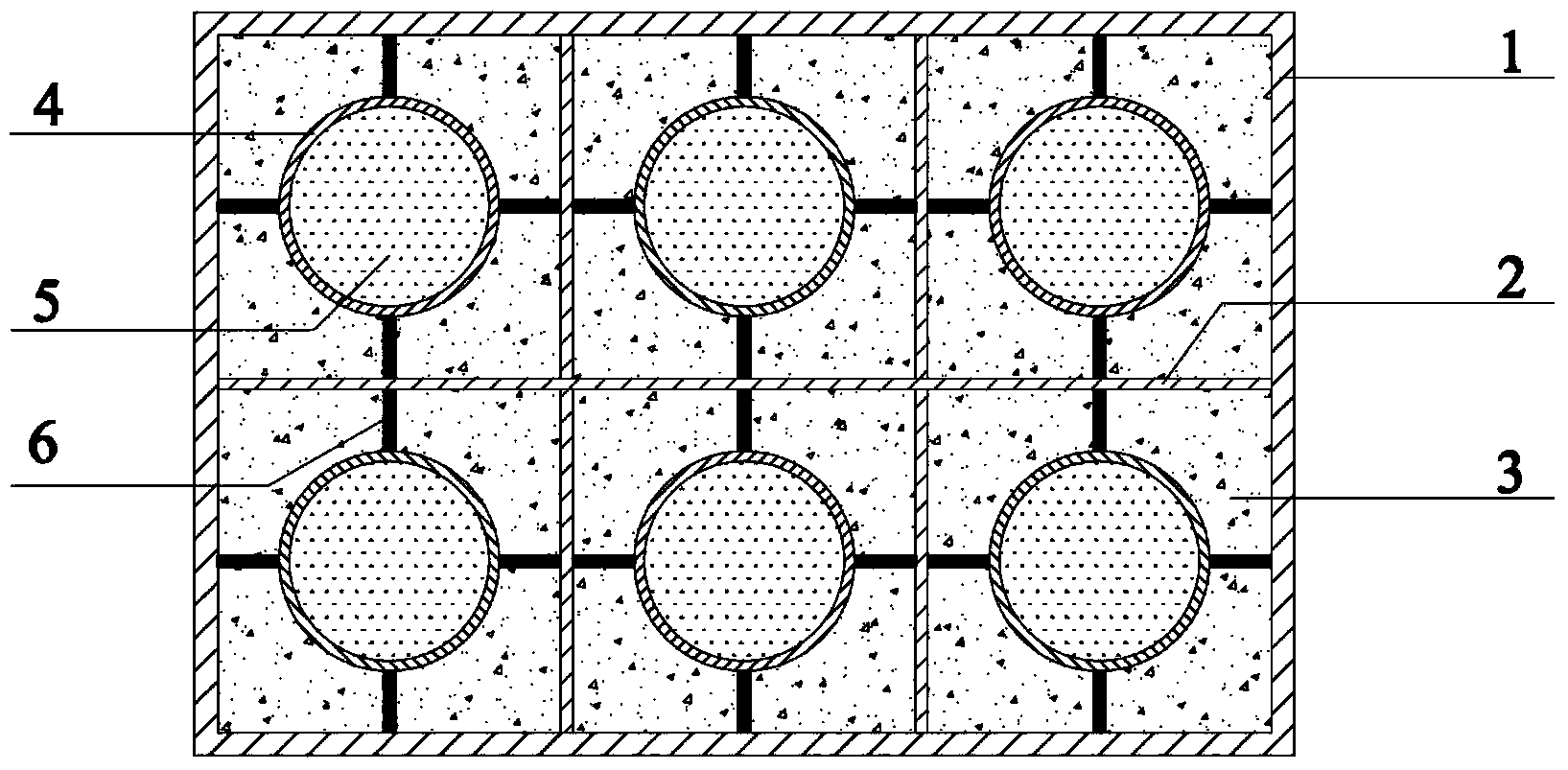

[0045] In this example, the difference from Example 1 is that the section of the polygonal steel pipe in Example 1 is a square, or there is little difference in size between the two directions, the inner partition is in the shape of a "ten", and the total number of round steel pipes is 4; In the embodiment, the cross-section of the polygonal steel pipe is rectangular, and the side lengths in the two directions differ greatly. Therefore, the inner partition adopts the shape of "牧", and the total number of round steel pipes is 6, as shown in image 3 shown.

[0046] In this embodiment, the rest of the structures, connections and manufacturing processes are the same as those in Embodiment 1.

Embodiment 3

[0048] In this embodiment, the difference from Embodiment 1 is that the cross-section of the polygonal steel pipe is pentagonal, and the shape of the inner partition is changed, such as Figure 4 shown.

[0049] In this embodiment, the rest of the structures, connections and manufacturing processes are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com