Vertical shaft working surface artesian flow sand layer slurry protecting rotary spraying grouting process

A technology for working faces and vertical shafts, which is applied in shaft equipment, shaft lining, mining equipment, etc., and can solve the problems of piles being unable to be formed by jet spraying, cement slurry washing away, and large water inflow from boreholes. The effect of small area and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

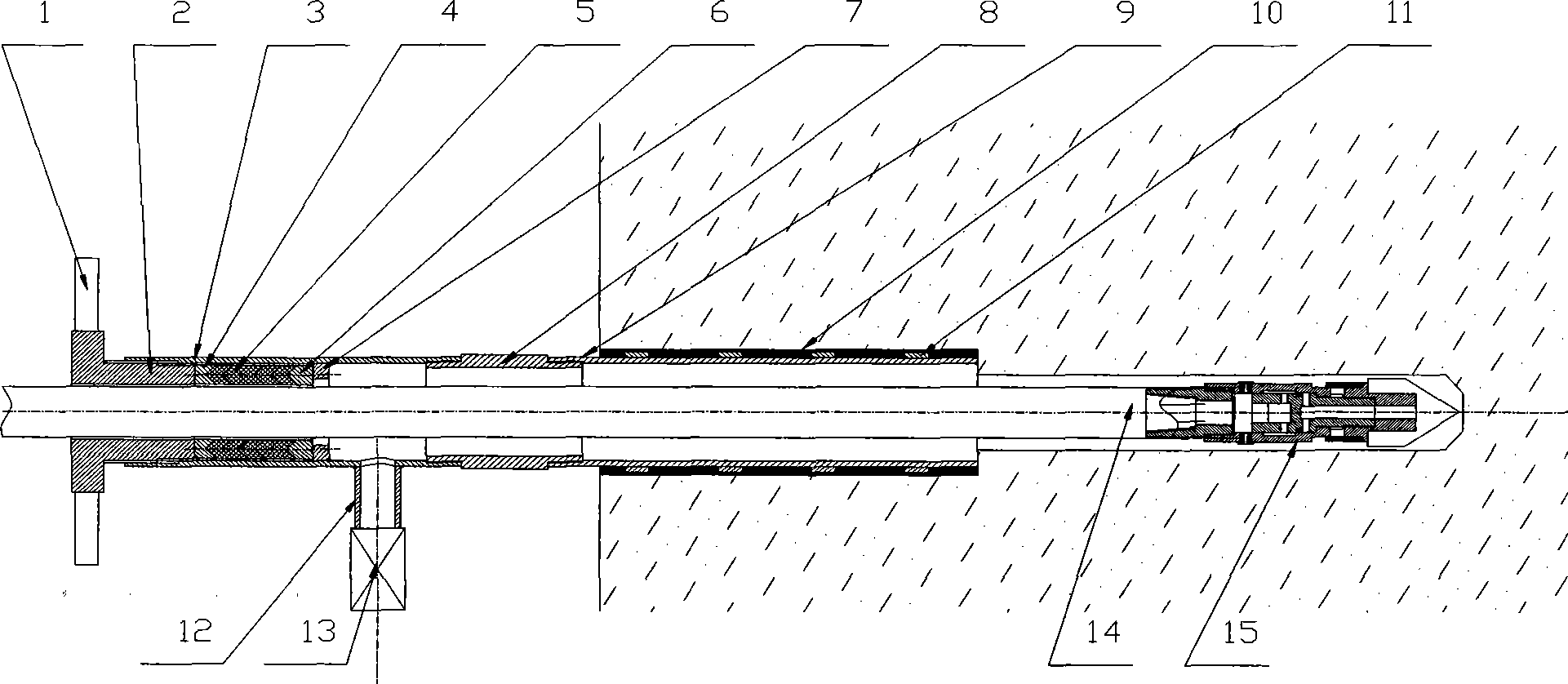

[0019] The process steps of the invention are as follows:

[0020] (1) In the working face of the vertical shaft under the condition of confined water, first implement the single-hole hole-forming process steps: in order to prevent the bottom of the quicksand layer and a large amount of water and sand in the hole-forming process, the concrete grout pad must be installed before construction. Construction: After the grout pad reaches 2-3 days of age, use the air DTH hammer impact drilling process to drill through the grout pad according to the designed hole position and angle, install the orifice casing and use CS double-liquid grouting After the orifice casing pipe reaches the age of 2 days, install the orifice anti-outburst device and the integrated drilling and spraying device to drill into the hole;

[0021] (2) Single hole pile forming process steps: double nozzles, diameter 2.5mm, slurry pressure greater than 20Mpa, flow rate greater than 120L / min; lifting speed 20-25cm / mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com