Complete equipment for complete regeneration of used clay sand

A complete regeneration and complete set of equipment technology, applied in foundry molding equipment, metal processing equipment, machinery for cleaning/processing of casting materials, etc. Incomplete regeneration of sand and other problems, to achieve the effect of improving casting performance, reducing emissions, and reducing waste sand emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of completely regenerating the old clay sand is to make the reclaimed clay sand meet the requirements of organic binder core-making sand, such as particle size distribution, acid consumption value, residual water content, mud content, angle coefficient, etc.

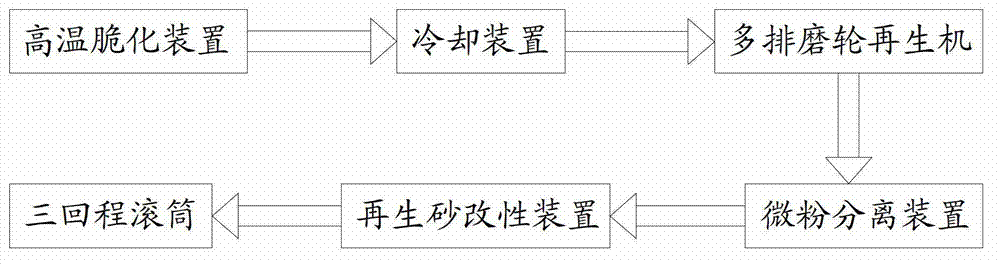

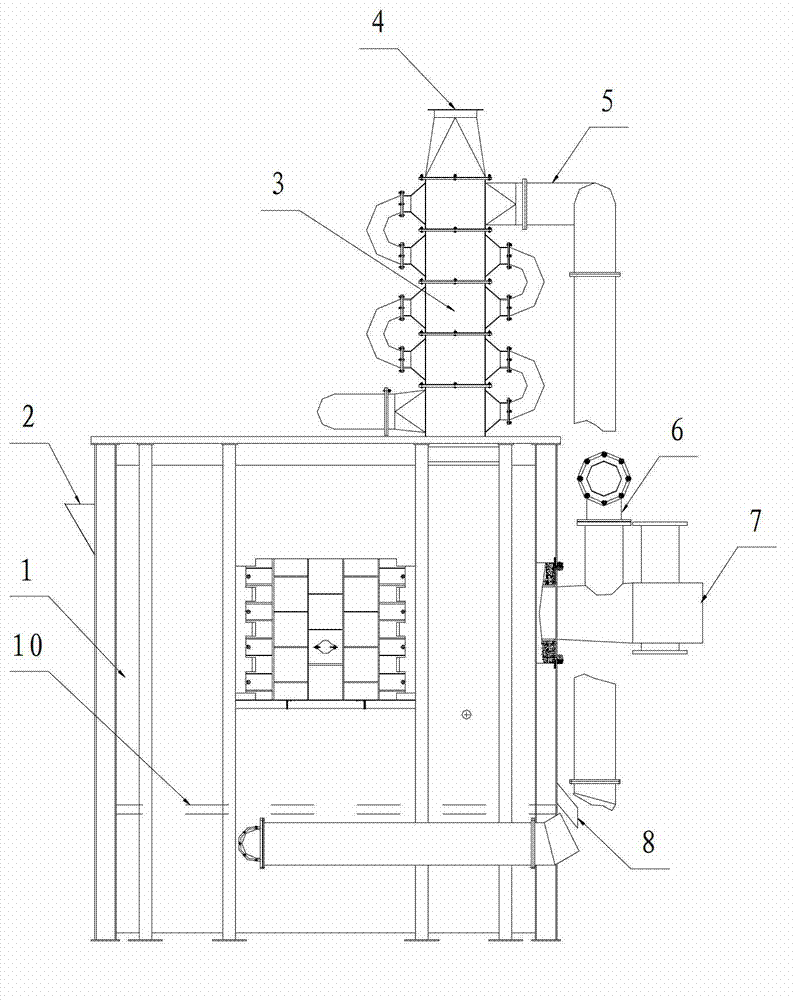

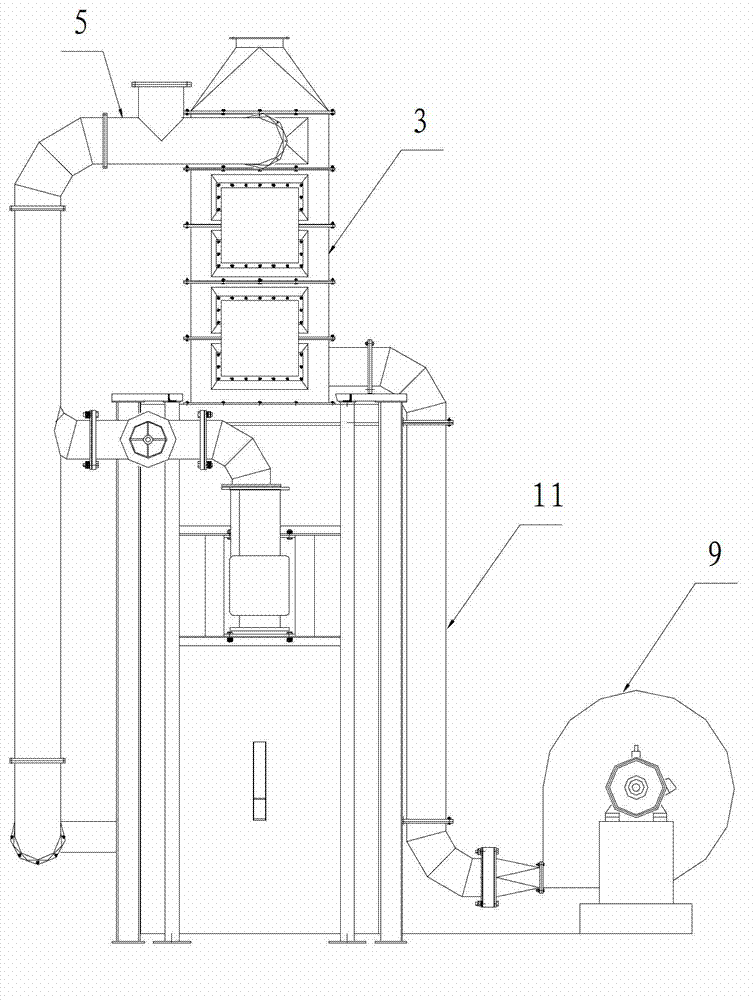

[0035] The embodiment of the present invention provides a complete set of equipment for the complete regeneration of old clay sand, which sequentially includes a high-temperature embrittlement device for high-temperature roasted old sand, an embrittled old sand cooling device for cooling high-temperature embrittled old sand, and an embrittlement used sand cooling device for cooling after cooling Multi-row grinding wheel regeneration machine for recycling old sand, micropowder separation device for separating fine powder in reclaimed sand, reclaimed sand modification device for improving reclaimed sand performance, and three-pass drum for drying modified sand, high temperature embrittlement Equipment, em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com