Garbage building material regenerating method and device

A recycling device and garbage technology, applied in chemical instruments and methods, wet separation, construction waste recycling, etc., can solve the problems of small use value and narrow use range, and achieve simple device, low production cost and wide use range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

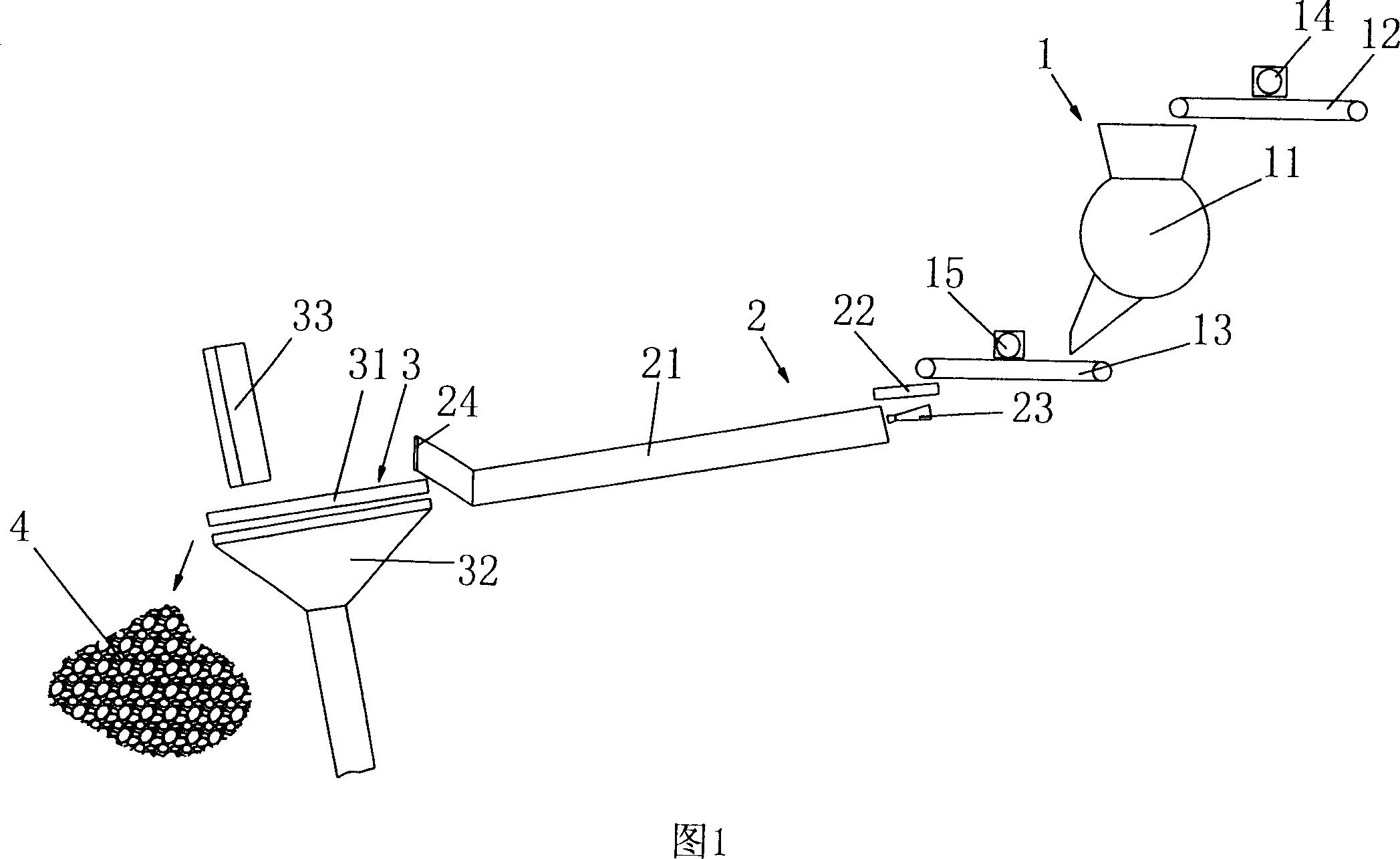

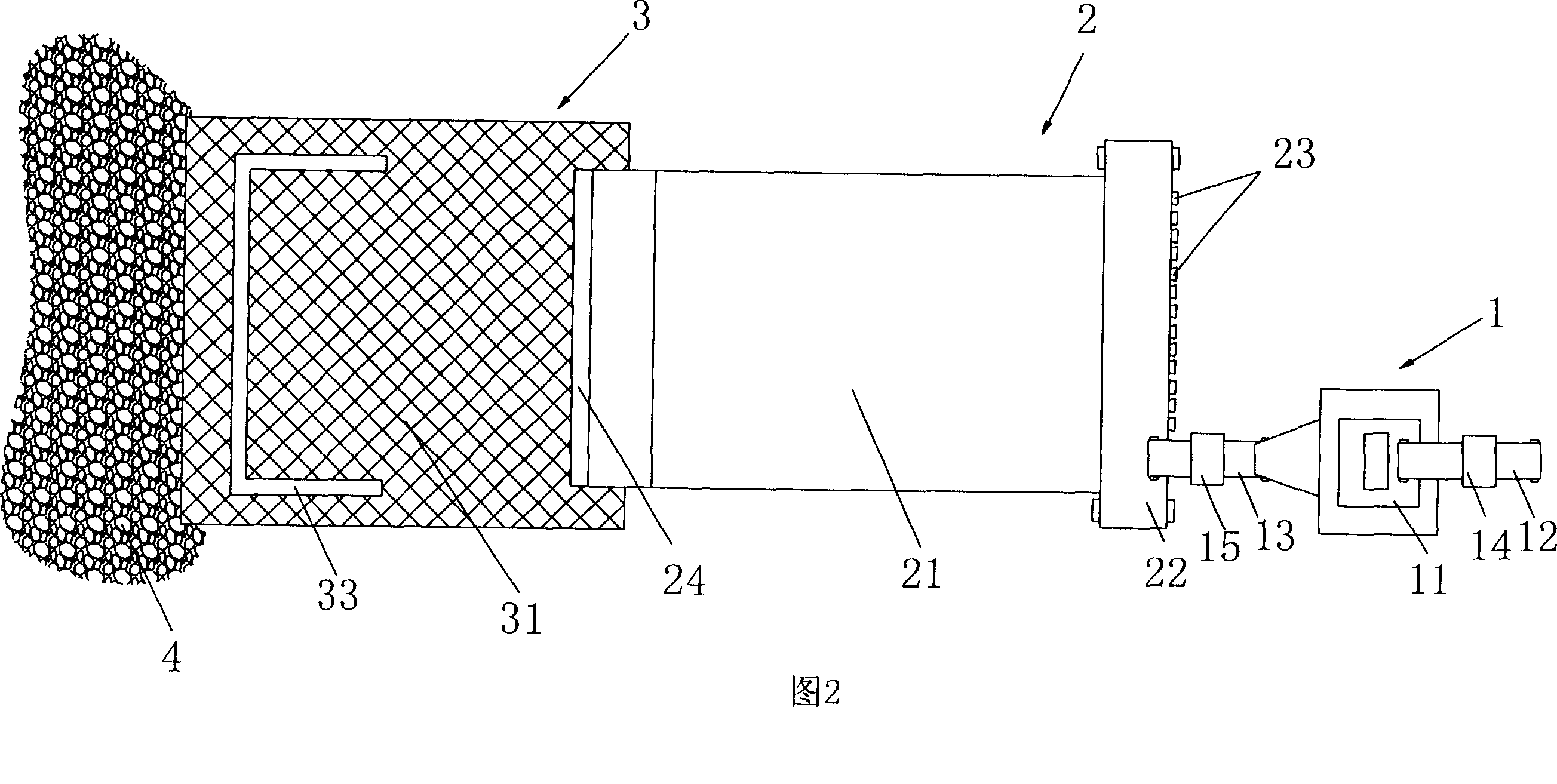

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0028] The invention can be used for the treatment of construction waste, waste incineration slag, road waste and the like, and regenerates them into high-quality building materials. Please refer to Fig. 1 and shown in Fig. 2, wherein the method for recycling building materials from garbage of the present invention is carried out with the following steps, comprising:

[0029] Step one, broken:

[0030] The construction waste or waste incineration slag or road waste to be processed is sent into the crusher 11 through the feeding conveyor belt 12 of the crusher 11 and is broken into smaller particles, and then output by the discharge conveyor belt 13 of the crusher 11; An electromagnetic iron absorber 14 is arranged above the conveyor belt 12 to remove iron for the first time from the material to be crushed. A strong magnetic roller 15 is arranged above the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com