Method for synthesizing unsaturated polyester resin by utilizing glycerol

A polyester resin, unsaturated technology, applied in the field of polymer compound synthesis, can solve problems such as easy gelation and difficult reaction control, and achieve the effect of reducing production costs and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

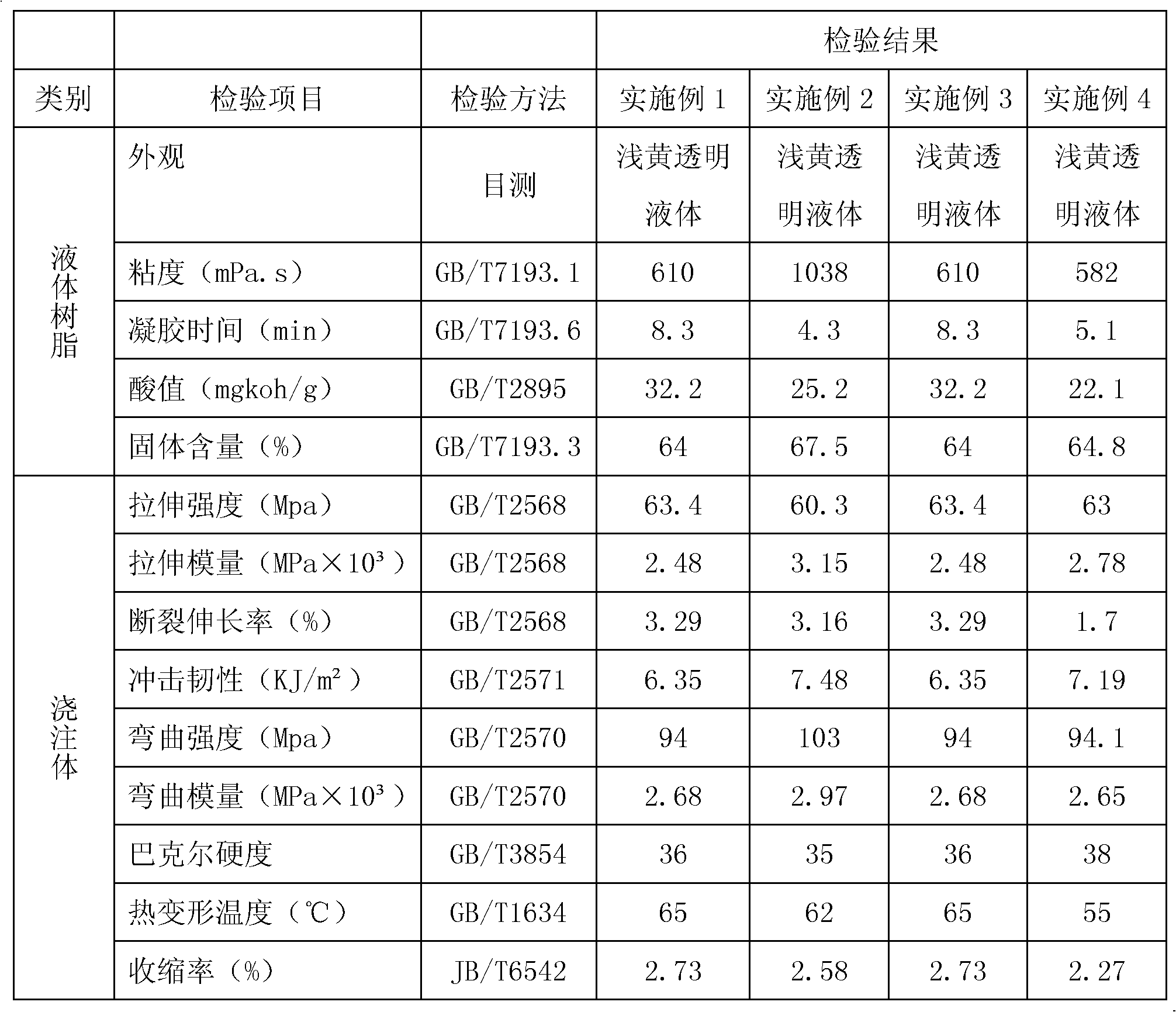

Examples

Embodiment 1

[0025] The raw material formula is as follows:

[0026] Phthalic anhydride 270kg, maleic anhydride 350kg, benzoic acid 200kg, glycerin 280kg, propylene glycol 80kg, diethylene glycol 200kg, styrene 800kg, hydroquinone 100g, paraffin 300g, copper naphthenate 40g, defoaming Dosage 1kg;

[0027] Preparation:

[0028] 1) Weigh each synthetic raw material component according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0029] 2) Add phthalic anhydride, maleic anhydride, benzoic acid, glycerin, propylene glycol and diethylene glycol into the reaction pot in the order of feeding liquid materials first and then solid materials, raise the temperature to 145°C, and pour into the reaction pot Introduce nitrogen gas, the flow rate of the nitrogen gas is 0.5m 3 / h, horizontal condenser water supply;

[0030] 3) When the material temperature rises to 150°C, turn on the mixer with a stirring rate ...

Embodiment 2

[0036] The raw material formula is as follows:

[0037] Phthalic anhydride 350kg, maleic anhydride 300kg, benzoic acid 110kg, glacial acetic acid 60kg, glycerin 95kg, propylene glycol 80kg, diethylene glycol 300kg, styrene 800kg, hydroquinone 110g, paraffin 350g, copper naphthenate 40g, defoamer 1kg;

[0038] Preparation:

[0039] 1) Weigh each synthetic raw material component according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0040] 2) Add phthalic anhydride, maleic anhydride, benzoic acid, glacial acetic acid, glycerin, propylene glycol, and diethylene glycol into the reaction pot in the order of feeding liquid materials first and then solid materials, and heat up to 148°C. Nitrogen is passed into the reaction pot, and the flow rate of the nitrogen is 0.5m 3 / h, horizontal condenser water supply;

[0041] 3) When the material temperature rises to 150°C, turn on the mixer with ...

Embodiment 3

[0047] The raw material formula is as follows:

[0048] Phthalic anhydride 270kg, maleic anhydride 350kg, benzoic acid 200kg, glycerin 240kg, propylene glycol 80kg, diethylene glycol 200kg, styrene 800kg, hydroquinone 100g, paraffin wax 300g, copper naphthenate 40g, defoaming Dosage 1kg;

[0049] Preparation:

[0050] 1) Weigh each synthetic raw material component according to the weight ratio, check and confirm whether the equipment, electrical appliances, instruments, valves and raw materials are normal;

[0051] 2) Add phthalic anhydride, maleic anhydride, benzoic acid, glycerin, propylene glycol, and diethylene glycol into the reaction pot in the order of feeding liquid materials first and then solid materials, raise the temperature to 145°C, and pour into the reaction pot Introduce nitrogen gas, the flow rate of the nitrogen gas is 0.5m 3 / h, horizontal condenser water supply;

[0052] 3) When the material temperature rises to 155°C, turn on the mixer with a stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com