Band steel running deviation control device

A technology for control devices and strip deviation, applied in manufacturing tools, transportation and packaging, heat treatment equipment, etc., can solve the problems of low efficiency and high labor costs, and achieve the effects of reducing production costs, simple layout, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

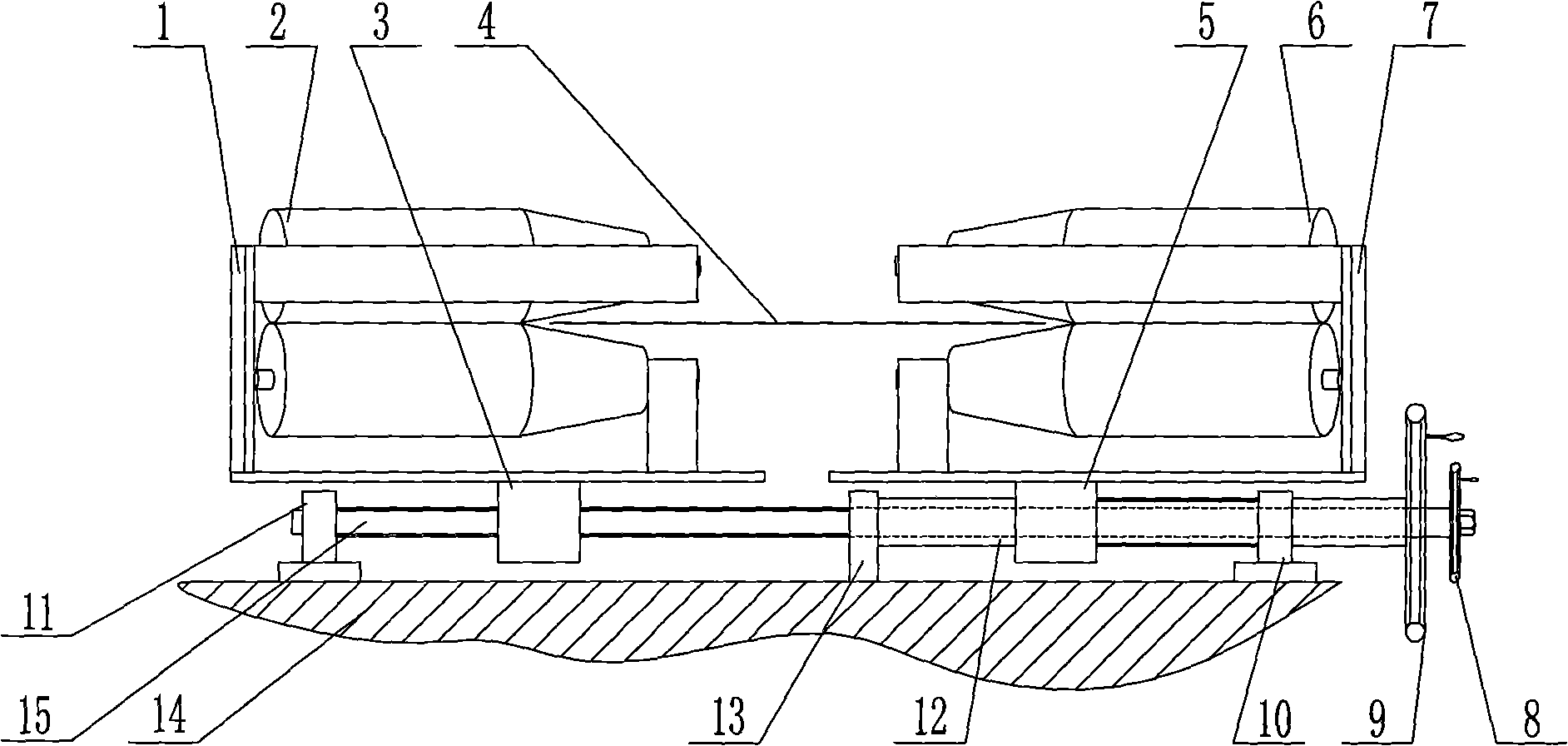

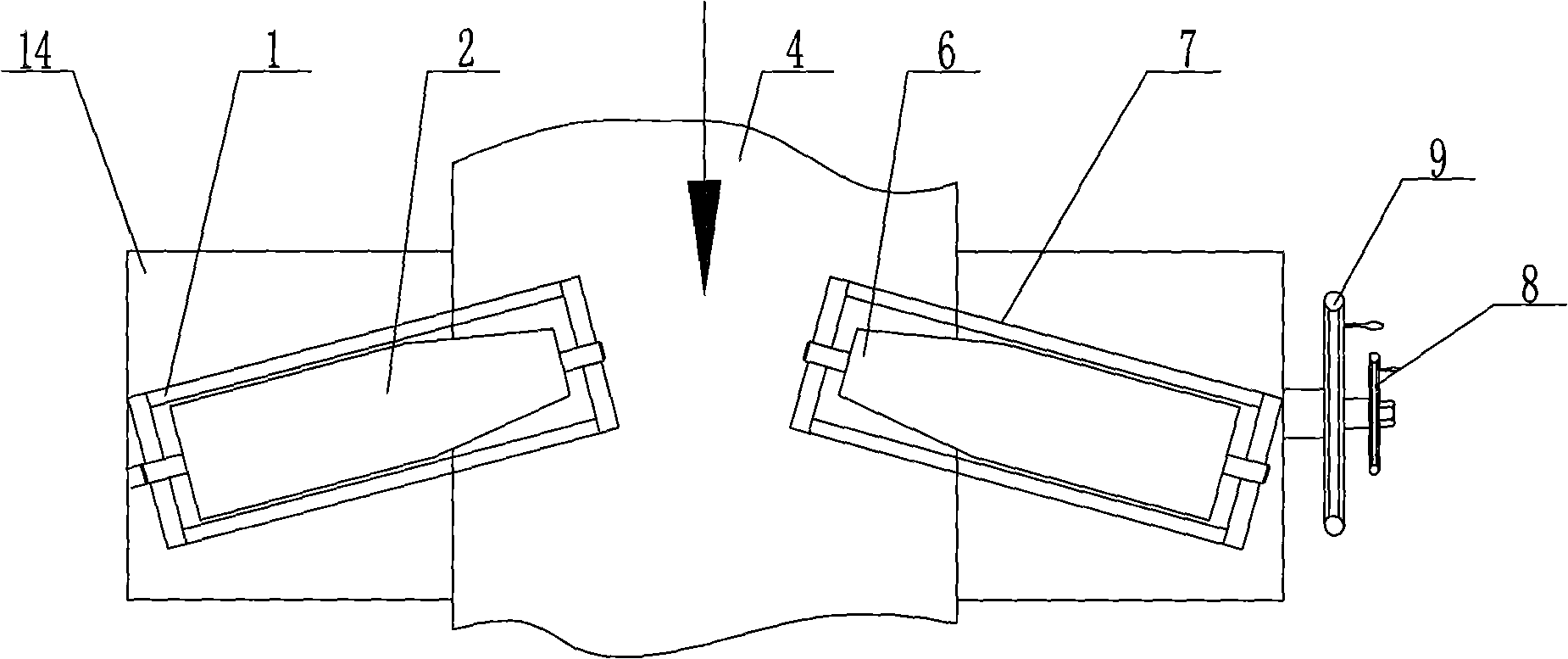

[0009] See figure 1 , figure 2 , the present invention comprises support, machine base 14, screw mandrel, screw mandrel connection adjustment handle, and it also comprises two pairs of correcting roller pair 2,6, and correcting roller pair 2,6 are symmetrically arranged up and down with strip steel 4 center as boundary line respectively, two The pair of rectifying rollers 2 and 6 are distributed face to face on the supports 1 and 7 on both sides of the machine base 14 and are respectively movably connected with the supports 1 and 7; the supports 1 and 7 are respectively installed on the machine base 14 through screw structure. The deviation correction roller is a cylindrical roller, and the outer ends of the cylindrical roller are respectively in the shape of a cone (see figure 2 ); two pairs of correcting roller pairs 2 and 6 maintain an included angle with the X-axis in the horizontal direction; the screw structure includes a left screw mechanism and a right screw structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com