Steel member manufacturing method

A manufacturing method and technology of steel components, applied in the field of manufacturing steel structural components, to achieve the effects of simple processing, increased yield, and reduced manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

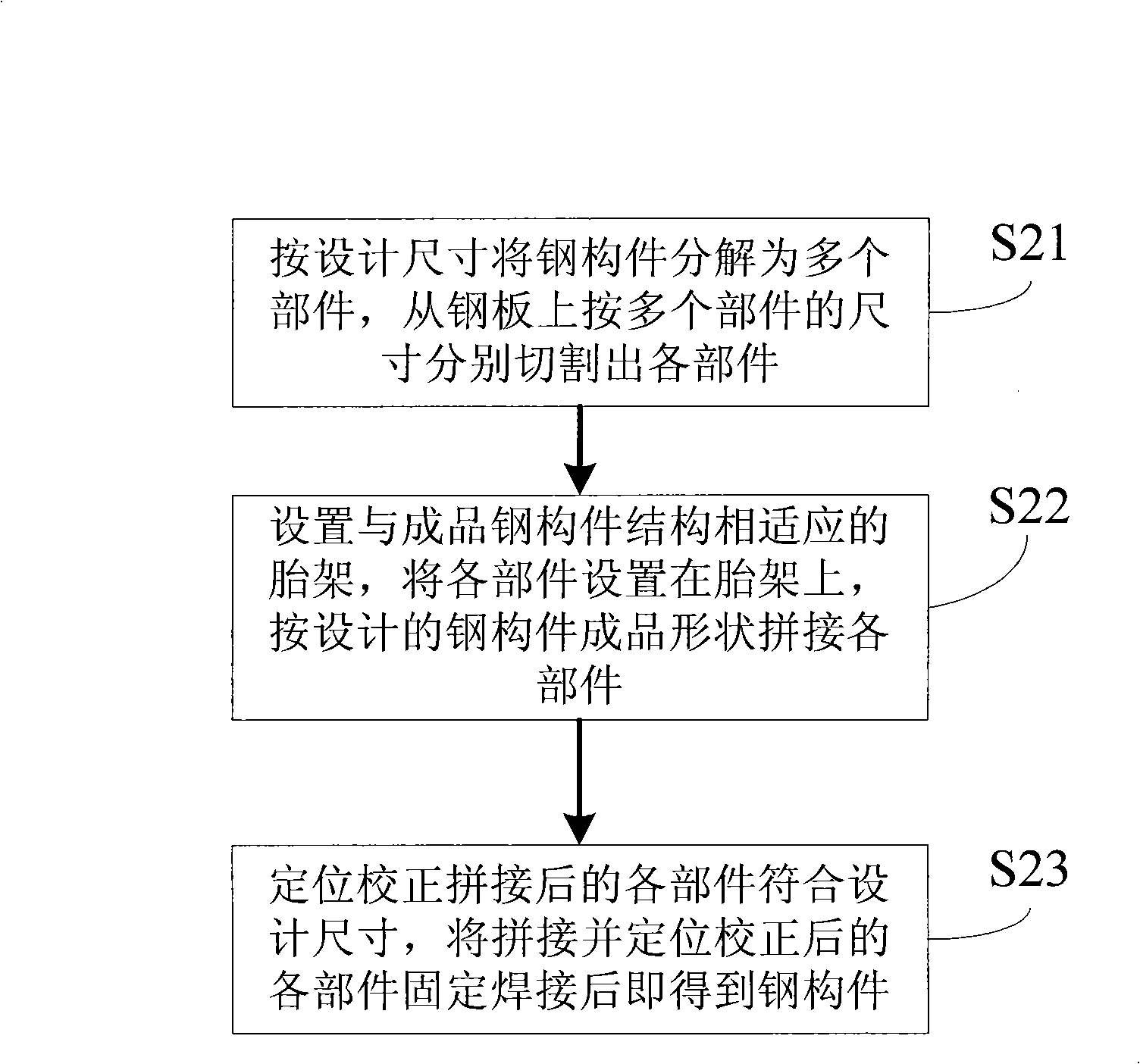

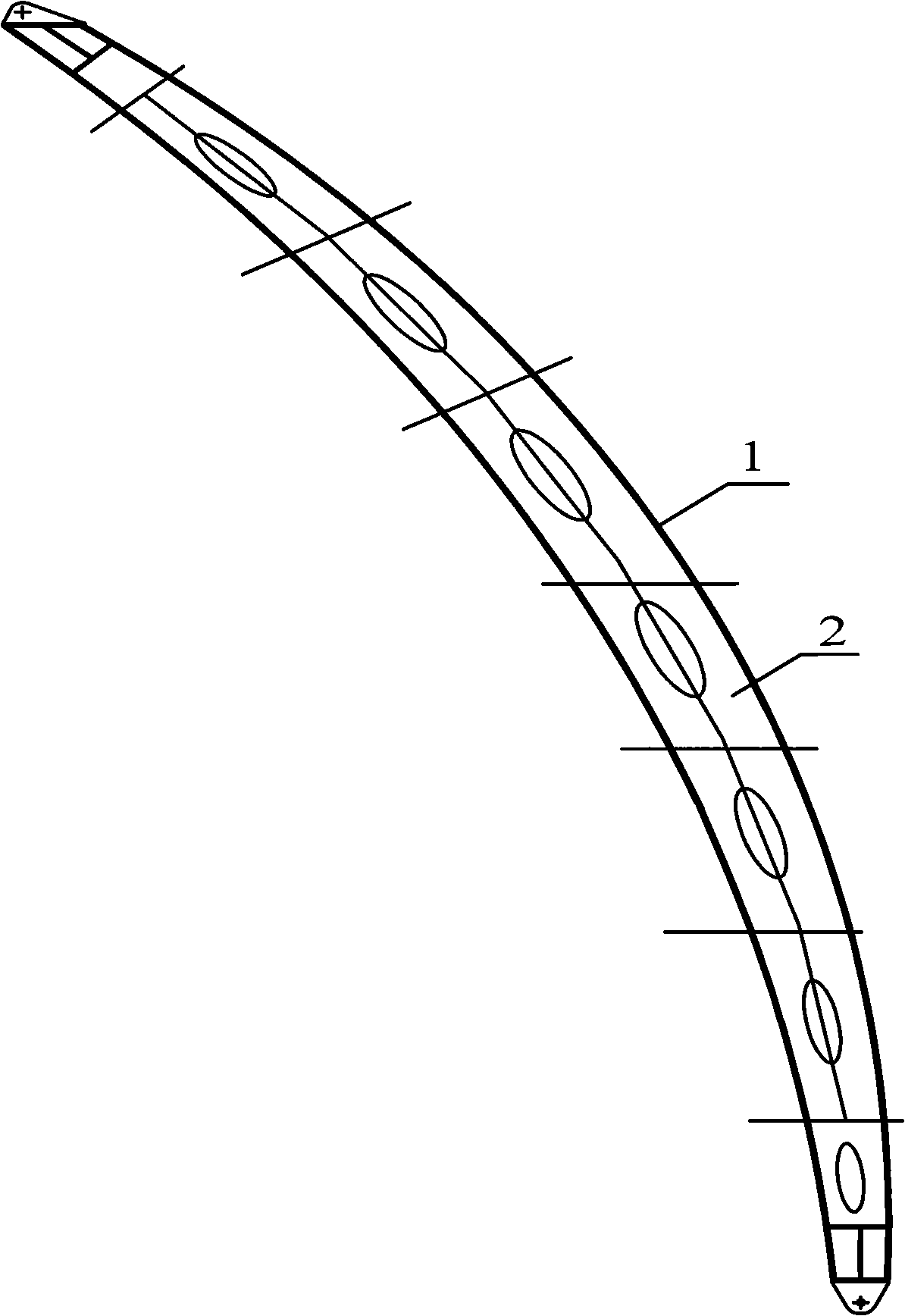

[0028] This embodiment provides a steel component manufacturing method, which is mainly used to produce special-shaped steel components with complex structures, such as figure 1 As shown, the method specifically includes:

[0029] Step S21, decomposing the steel member into multiple parts according to the design size, and cutting out each part from the steel plate according to the size of the multiple parts;

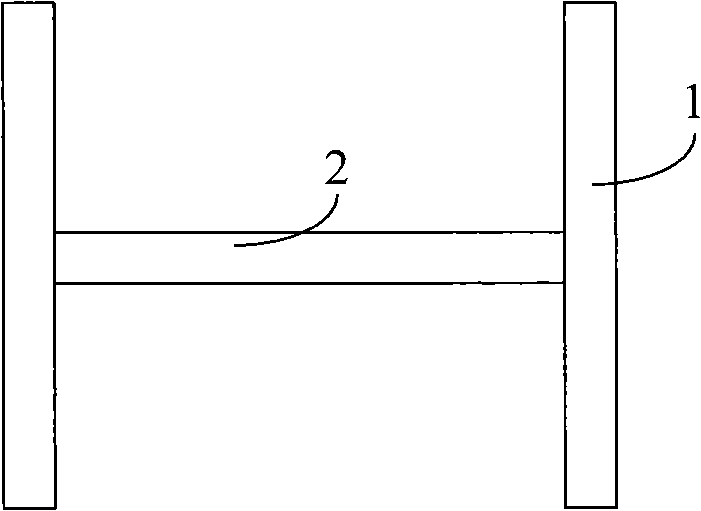

[0030] Step S22, setting a tire frame suitable for the structure of the finished steel member, setting each component on the tire frame, and splicing each component according to the designed shape of the finished steel component;

[0031] Step S23 , positioning and correcting the spliced components to meet the design dimensions, fixing and welding the spliced and positioned and corrected components to obtain the steel member.

[0032] In the above method, in step S21, the parts of steel components that meet the design size are cut from the steel plate specifically i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com