Production method and production equipment of special material for polypropylene melt-blown non-woven fabric

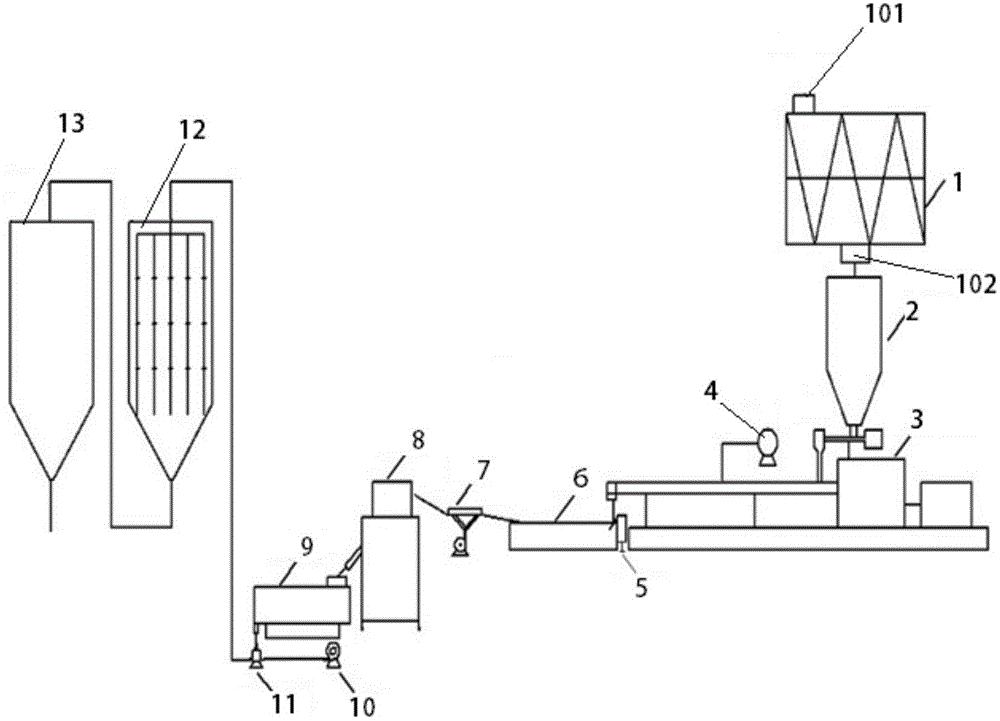

A polypropylene melt-blown and production equipment technology, applied in the field of non-woven fabric production, can solve the problems of too wide molecular weight distribution, insufficient reaction time, and difficulty in forming, and achieve the effects of stable product melt finger, complete reaction, and suitable molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the production of PF1500 melt-blown special material.

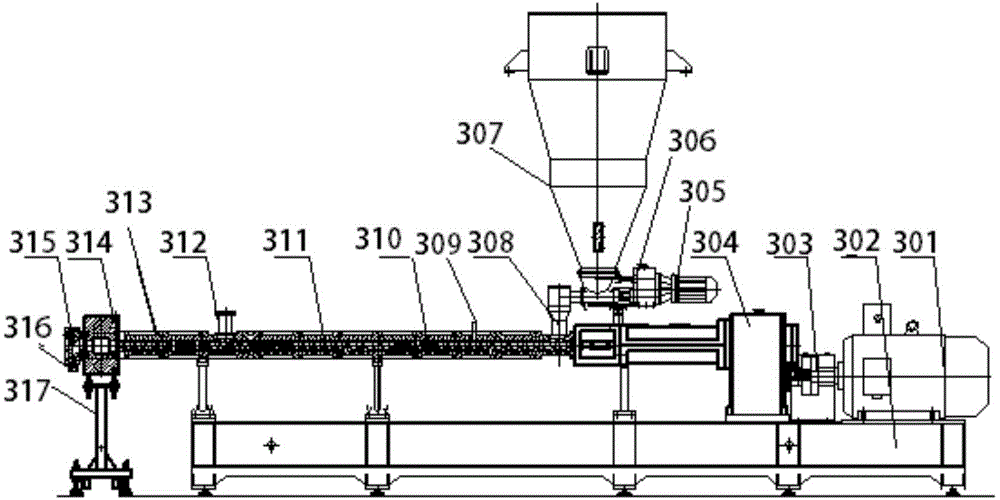

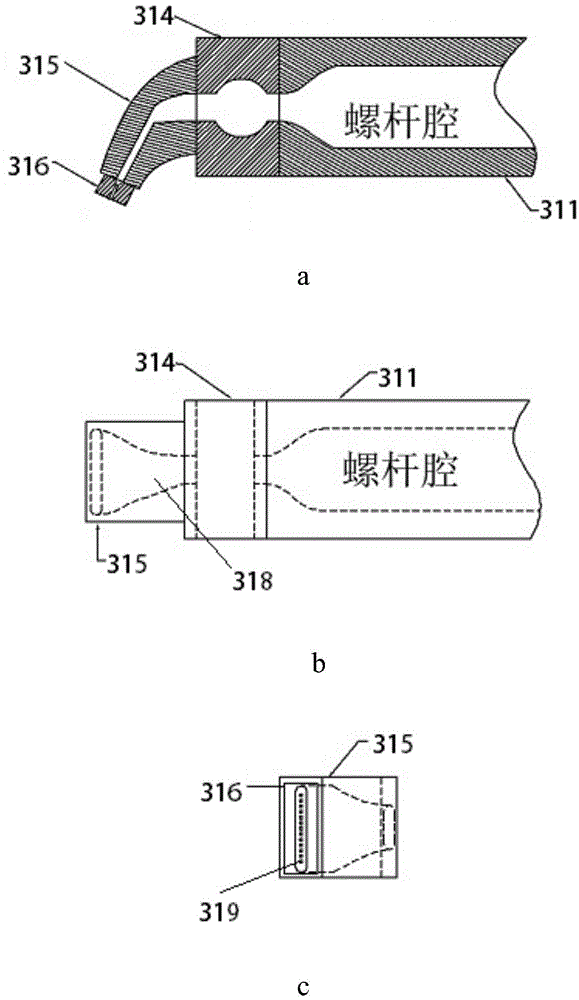

[0048] A certain weight of polypropylene powder with a melting point of 30g / 10min, its properties are shown in Table 1, and it is prepared according to the ratio of Table 2 with stabilizers and lubricants, mixed evenly in the mixer and put into the intermediate silo to become Polypropylene blends to be processed. The intermediate silo is connected with the feeding hopper of the twin-screw extruder. The twin-screw extruder runs according to the operating parameters of Table 4, and the degradation agent is added in the middle of the second to the third section of the twin-screw extruder through the degradation agent pump, and the addition is controlled by the ratio of the degradation agent and the polypropylene mixture in Table 3, That is, the feed load in Table 4 determines the feed amount of the mixture, and the addition amount of the degradation agent is adjusted according to the ratio requirements ...

Embodiment 2

[0060] Embodiment 2: the production of PF1200 melt-blown special material.

[0061] The properties of polypropylene pellets with a certain weight and melting index of 3g / 10min are shown in Table 6, and the stabilizer and lubricant are prepared according to the ratio of Table 7. After being mixed evenly in the mixer, they are put into the intermediate silo to become processed polypropylene mixture. The intermediate silo is connected with the feeding hopper of the twin-screw extruder. The twin-screw extruder runs according to the operating parameters in Table 9, and the degradation agent is added in the middle of the second to the third section of the twin-screw extruder through the degradation agent pump, and the addition is controlled by the ratio of the degradation agent and the polypropylene mixture in Table 8, That is, the feed load in Table 9 determines the feed amount of the mixture, and the addition amount of the degradation agent is adjusted according to the ratio requ...

Embodiment 3

[0072] Embodiment 3: the production of PF1800 melt-blown special material.

[0073]The properties of polypropylene with a certain weight melting index of 35g / 10min are shown in Table 11. The powder, stabilizer and lubricant are prepared according to the ratio in Table 12. After being mixed evenly in the mixer, they are put into the intermediate silo to become processed. polypropylene mixture. The intermediate silo is connected with the feeding hopper of the twin-screw extruder. The twin-screw extruder runs according to the operating parameters in Table 14, and the degradation agent is added in the middle of the second to the third section of the twin-screw extruder through the degradation agent pump, and the addition is controlled according to the ratio of the degradation agent and the polypropylene mixture in Table 13, That is, the feed load in Table 14 determines the feed amount of the mixture, and the addition amount of the degradation agent is adjusted according to the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com