Closed coal yard

A technology of coal yards and coal piles, applied in the field of closed coal yards, can solve the problems of continuous expansion restrictions, high degree of automation, and limited reserves of a single seat, and achieve the effect of continuous expansion convenience, high degree of automation, and large reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

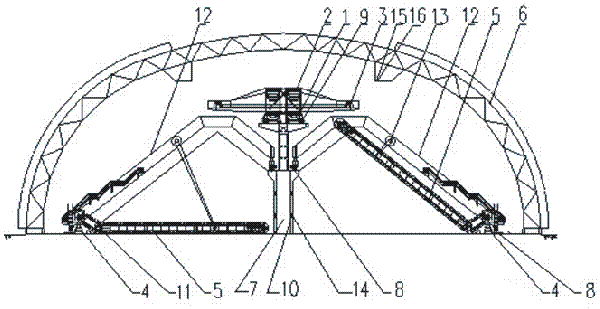

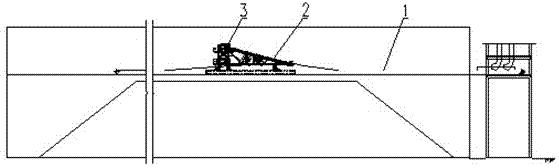

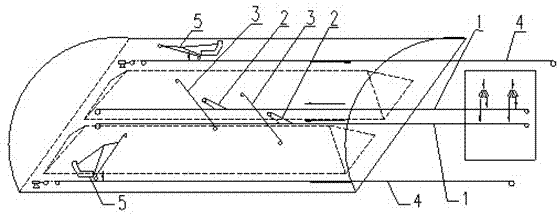

[0031] Such as Figure 1-3 As shown, a closed coal yard includes a closed network frame, a feeding mechanism, a blanking mechanism and a reclaiming mechanism.

[0032] The closed network frame 6 is a strip arched sealing structure with a semicircular cross section. This closed structure solves the environmental pollution problem of the coal yard to the outside world. The cross-section is a semicircular structure, and the coal piles are symmetrically arranged on both sides with the center line as the symmetry line. From the perspective of the formation shape of the coal piles in the present invention, the coal piles formed in the semicircular space have the highest utilization rate and large reserves. The elongated arched structure can be extended freely in the length direction, so as to facilitate the expansion of the factory building and meet the requirements of the expansion of the site. It is especially suitable for large-scale coal storage and distribution base projects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com