Automatic assembly production line of wall socket

An automatic assembly and production line technology, applied in the assembly/disassembly of contact parts, etc., can solve the problems of large space occupation and low efficiency, achieve high production efficiency, high degree of automation, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

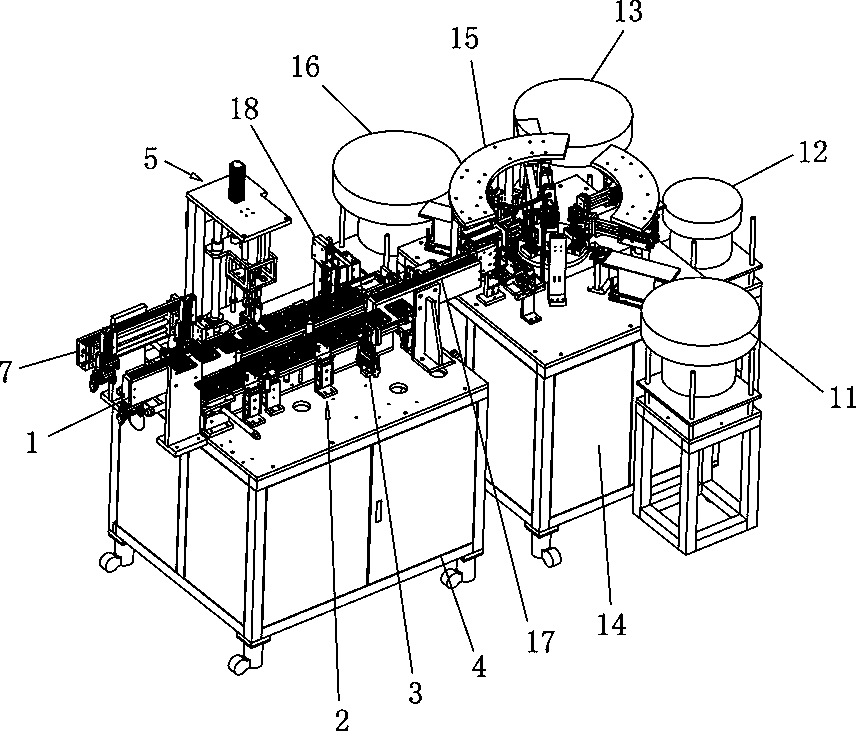

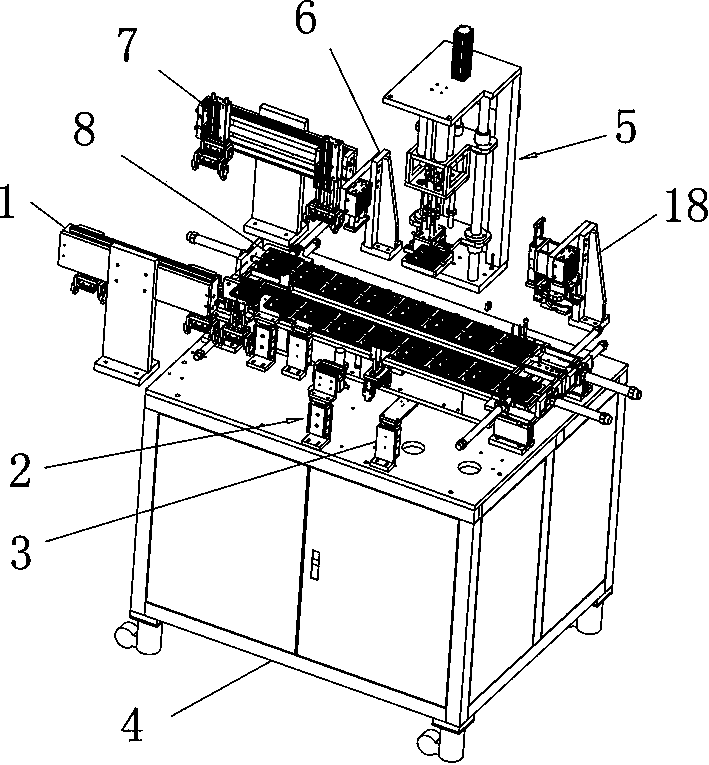

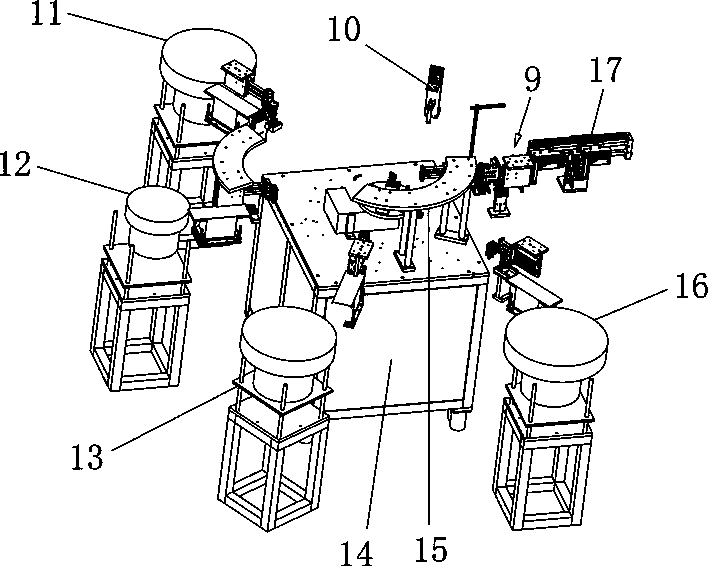

[0025] like figure 1 , figure 2 , image 3 As shown, a socket automatic assembly production line includes a bottom box automatic assembly part and a panel bottom box automatic assembly part, and the bottom box automatic assembly part includes a first chassis 14, and a correction device is provided on the first chassis 14. Station 10, upper L sheet station 11, upper spring sheet station 12, upper N sheet station 13, turntable 15 and upper bottom shell station 16, the turntable 15 is located at the center of the first cabinet 14, and the turntable 15 is A number of bottom shell jigs are provided, and the correction station 10, the upper L-piece station 11, the upper elastic piece station 12, the upper N-piece station 13 and the upper bottom case station 16 are distributed around the turntable 15 in sequence, The turntable structure design is adopted, and several stations are distributed around it in sequence. This structure design takes up little space and has high productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com