Automatic clamping mechanical hand device for milling machining optical lens

An optical lens and manipulator technology, applied in manipulators, optical surface grinders, metal processing equipment, etc., can solve the problems of unreliable guarantee of workpiece processing quality, inability to adapt to mass production, and fatigue of operators. High precision, convenient operation, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

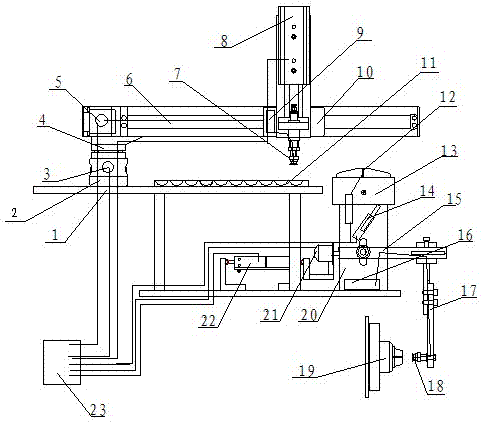

[0016] Such as figure 1 As shown, the optical lens milling and grinding processing automatic clamping manipulator device of the present invention includes a blank storage platform, a blank retrieving mechanism, an intermediate transfer mechanism, a blank feeding mechanism and a control cabinet 23, wherein the blank retrieving mechanism is located at the The top of the blank storage platform 1, the intermediate transfer mechanism is located on one side of the blank storage platform 1, the blank feeding mechanism is connected with the intermediate transfer mechanism, and the control cabinet 23 is respectively connected to the blank storage through wires. The mechanism, the intermediate transfer mechanism and the blank feeding mechanism are connected. The blank retrieving mechanism includes an X-axis slide rail 2 and a Y-axis slide rail 6. The X-axis slide rail 2 is fixed on the table top of the blank storage stand 1. The Y-axis slide rail 6 passes through the X-axis The axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com