Combination type recovering machine for residual-film between seedlings

A combined, residual film technology, applied in the field of agricultural machinery and tools, can solve the problems of inability to recover residual film, high labor intensity, low recovery rate, etc., and achieve the effects of improving efficiency and operating range, reasonable structure, and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

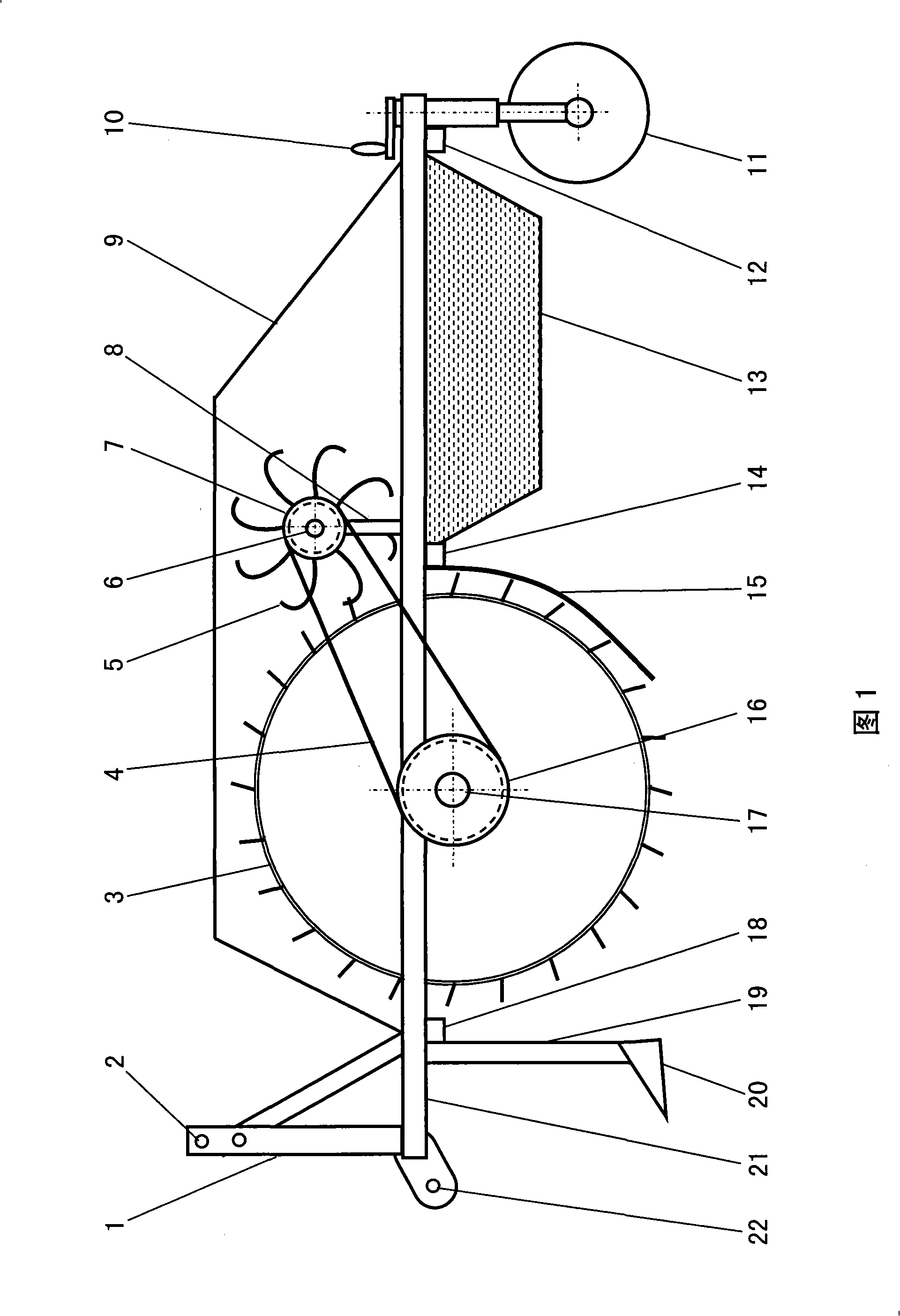

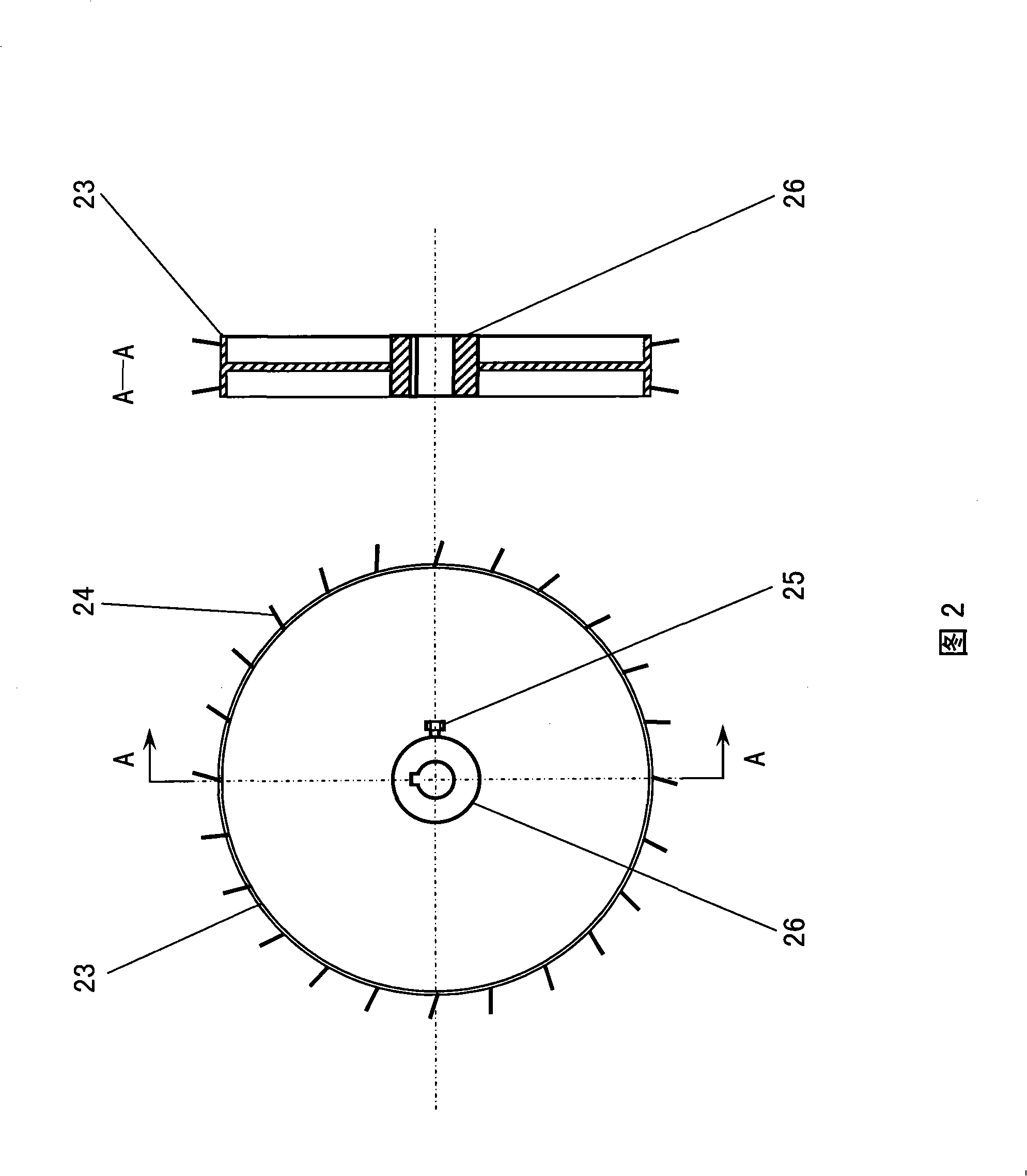

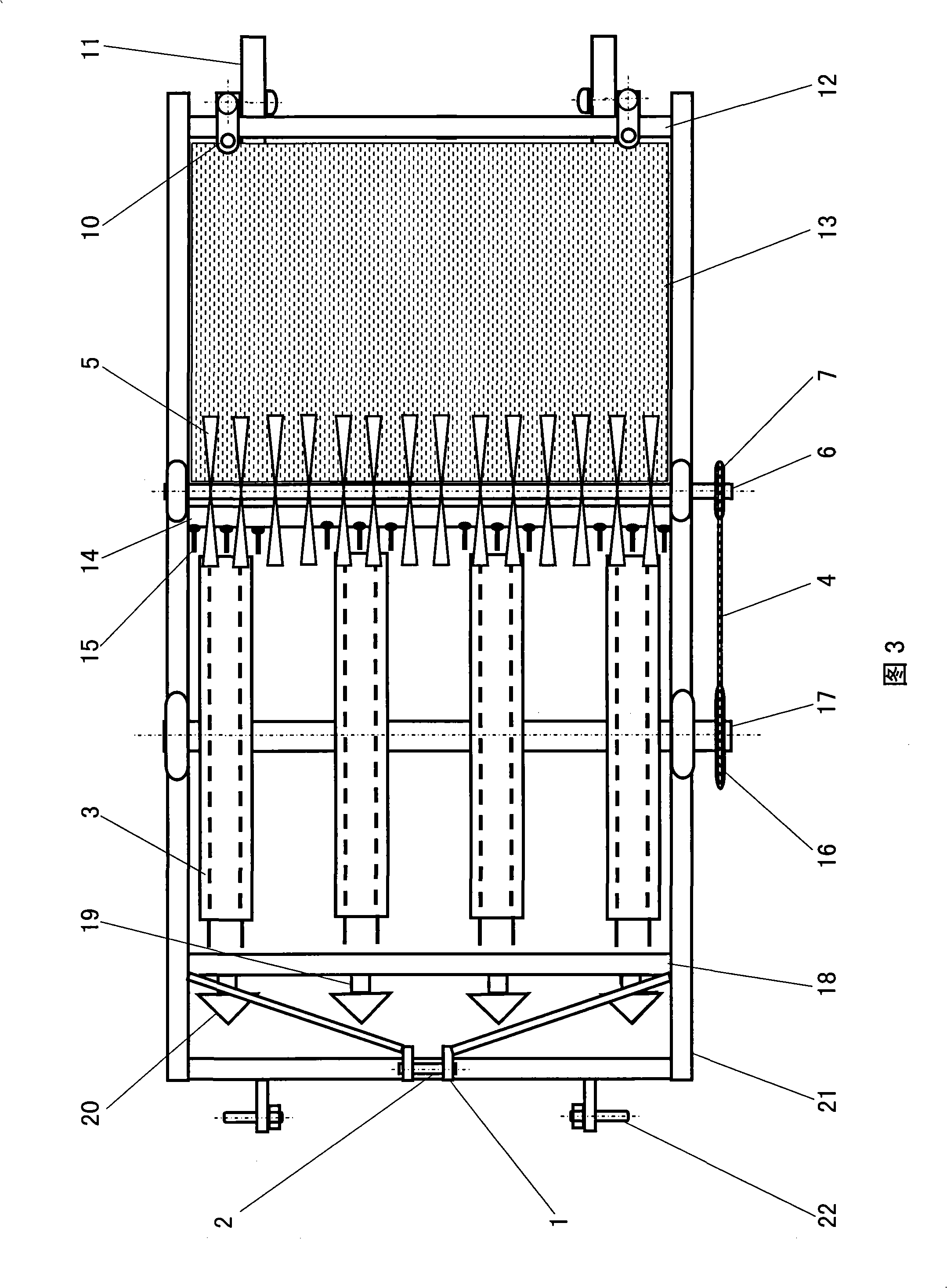

[0021] Embodiment 1 (residual film recovery operation between farmland seedlings)

[0022] According to the number of rows of crops and the row spacing in the working width of the implement, the configuration quantity of the loosening shovel 20, the split disc type film lifting wheel 3 and the elastic tooth film picking rake 15 are determined, and the loosening shovel 20 is adjusted according to the row spacing of the crops The distance between them, the distance between the split-spoke-disc type film-lifting wheels 3 and the distance between the spring-toothed film-picking rakes 15, and the depth-limiting wheel 11 is adjusted to the operating depth according to the agronomic requirements through the depth-limiting wheel adjustment device 10, Realize the agronomic requirements of farmland seedling operation and the recovery of residual film.

Embodiment 2

[0023] Embodiment 2 (recovery operation of the entire residual film of the machine tool)

[0024] According to the working width of equipment, the loosening shovel 20, the split spoke disc type film removal wheel 3 and the spring tooth film picking rake 15 are configured in full width, between the loose soil shovels 20, between the split spoke disc type film removal wheels 3 and There is no gap between the spring-tooth film picking rakes 15, and the depth-limiting wheel 11 is adjusted to the operating depth according to the agronomic requirements through the depth-limiting wheel adjustment device 10, so as to realize the agronomic requirements and the recovery of residual film during the entire operation of the machine tool.

[0025] When the tractor pulls the combined inter-seedling residual film recycling machine, the soil loosening shovel 20 loosens the soil, and the split-spoke disc-type film removing wheel 3 cooperates with the spring-tooth film picking rake 15 to remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com