Guide chute and bucket wheel stacker-reclaimer with same

A bucket-wheel stacker-reclaimer and material guide chute technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high cost, large occupied space, and increased control difficulty, and achieve low manufacturing cost and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

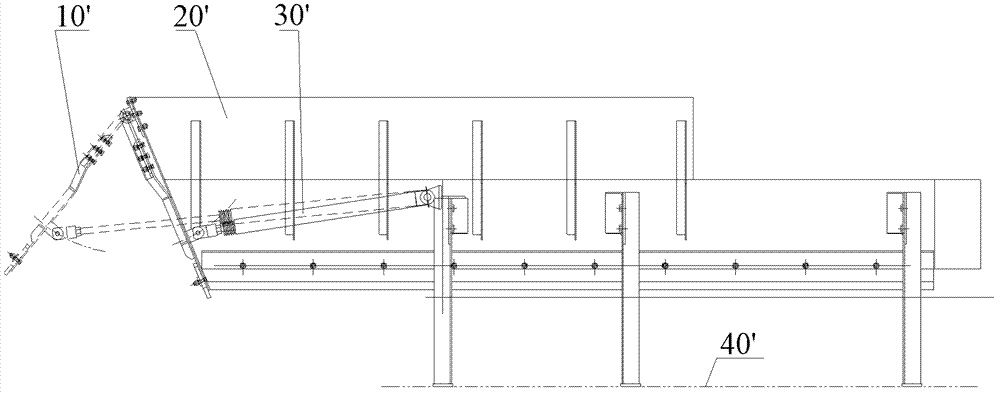

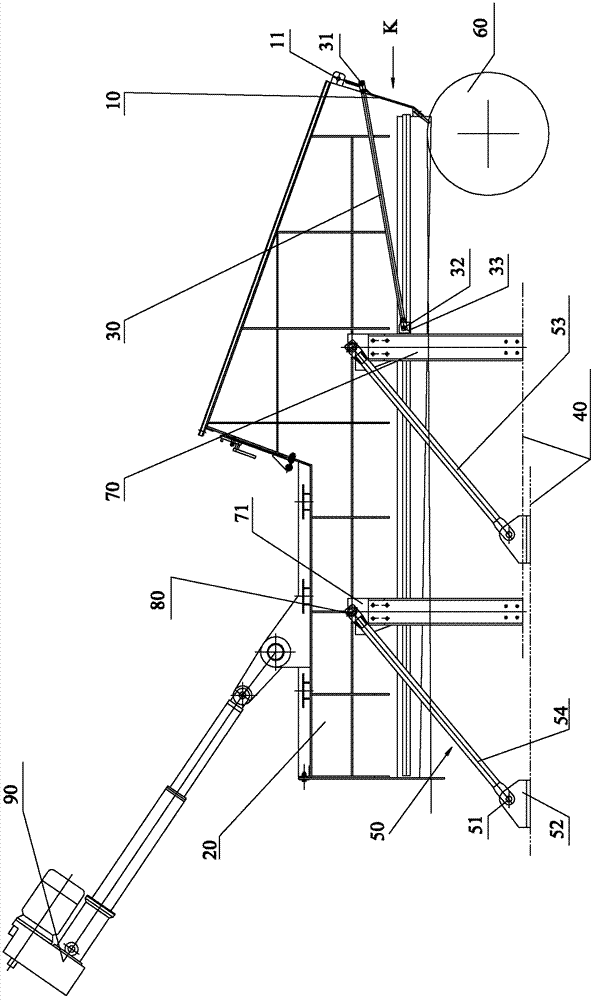

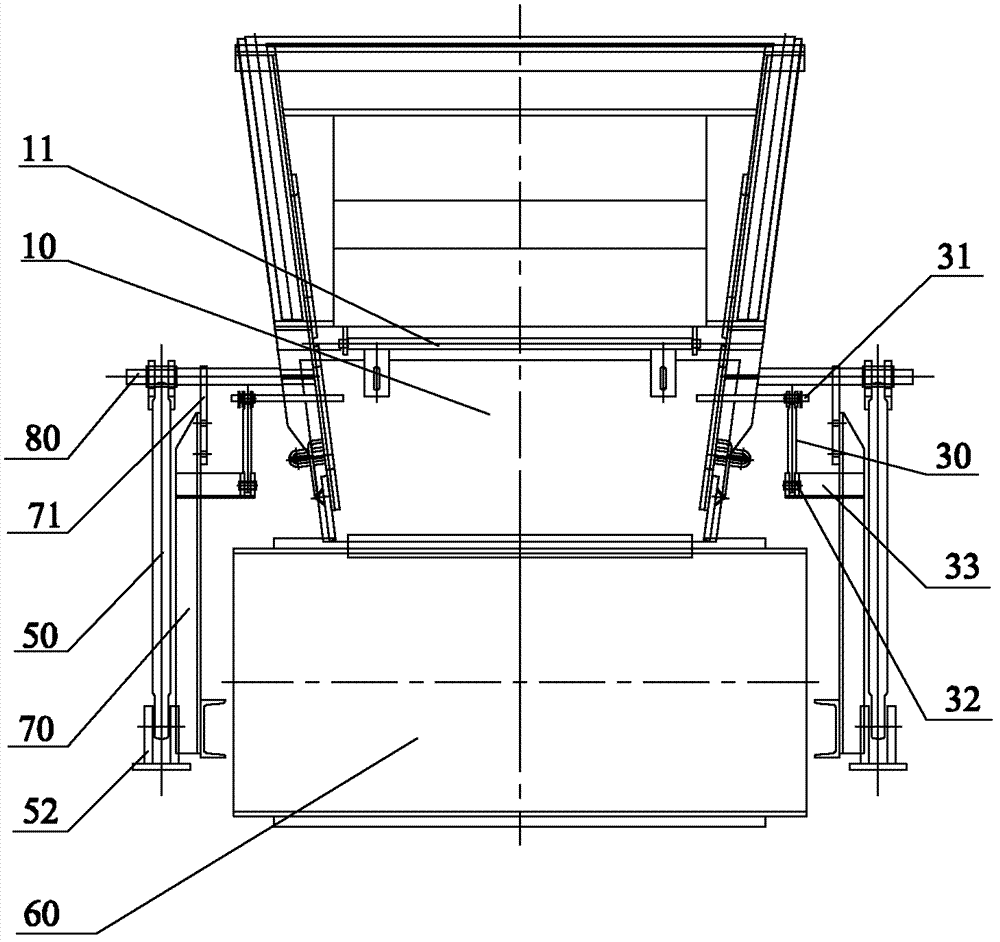

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0023] Such as figure 2 As shown, the feed chute according to the present invention includes a trough body 20 and a support leg 70 supporting the trough body 20, the support leg 70 is arranged on the boom portion 40 of the bucket wheel stacker and reclaimer, and the trough body 20 One end is provided with a stopper 10, and also includes a first rocker part 30, its first end is rotatably connected with the stopper 10, and its second end is rotatably connected to the first fixed position on the outside of the tank part 20. connected. Preferably, the first fixing position is on the supporting leg 70 .

[0024] Such as image 3 As shown, one end of the support leg 70 is fixedly connected to the arm frame 40 of the bucket wheel stacker and reclaimer, and a first connecting rod 33 protruding inward is fixedly arranged on the inner side of the tank body part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com