Automatic material taking machine for storage

An automatic retrieving and warehousing technology, which is applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of high energy consumption, long time, and low efficiency of driving, and achieve the effect of improving the efficiency of retrieving goods and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

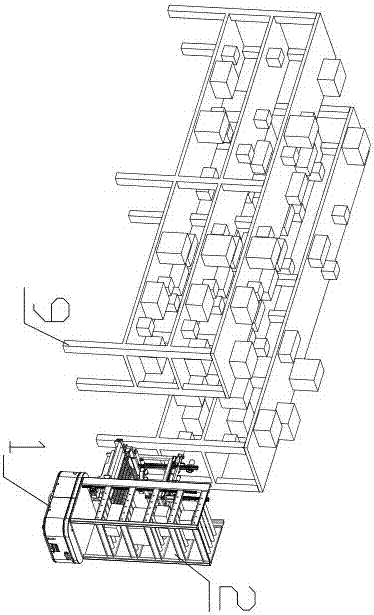

[0041] Example 1, such as figure 1 As shown, a storage automatic reclaimer works in the storage workshop. The storage workshop includes a plurality of shelves 9, and the shelves 9 may have a multi-layer structure, and goods packages of different sizes are placed on each floor. A roadway for the storage automatic reclaimer to pass is arranged between the adjacent shelves 9 .

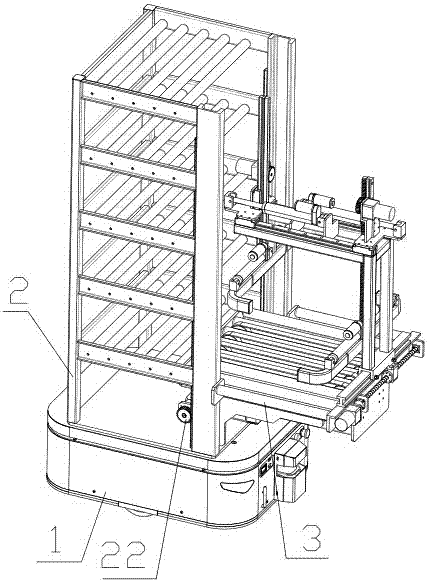

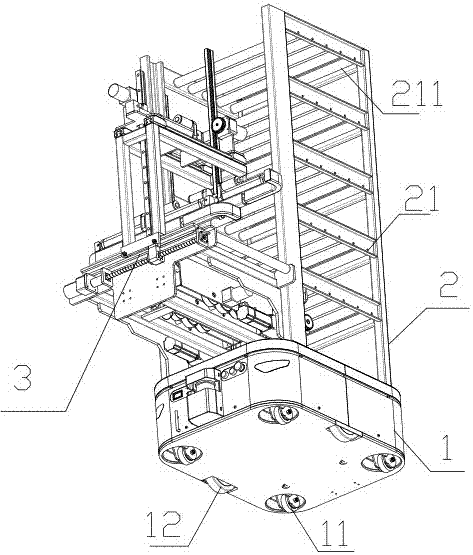

[0042] Such as figure 2 with image 3 As shown, this kind of storage automatic reclaimer includes a walking device 1, relies on the walking device 1 to walk in the roadway, and also includes a storage device 2 connected to the walking device 1, a retrieving device 4 that can be extended and retracted, and a retrieving device 4 for retrieving The goods obtained by the cargo device 4 are transferred to the bin transfer assembly 3 on the storage device 2. The storage device 2 includes at least two layers of storage racks 21 at different heights. The storage racks 21 include a storage transfer device 211....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com