Method for controlling operation speed of cantilever crane rotating mechanism of cantilever type bucket wheel reclaimer

A technology of slewing speed and slewing mechanism, which is applied in the direction of electric speed/acceleration control, etc., can solve the problems of affecting the efficiency of reclaiming and slow slewing speed, and achieve the effect of improving the efficiency of reclaiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

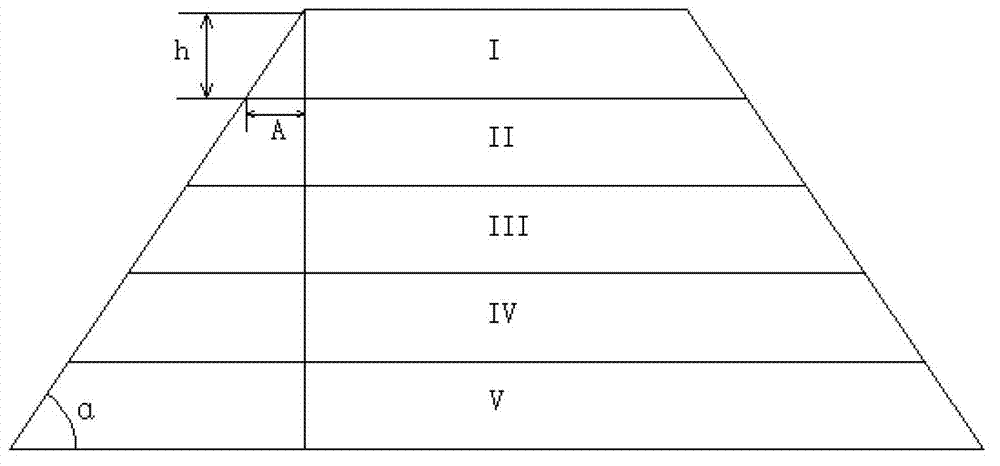

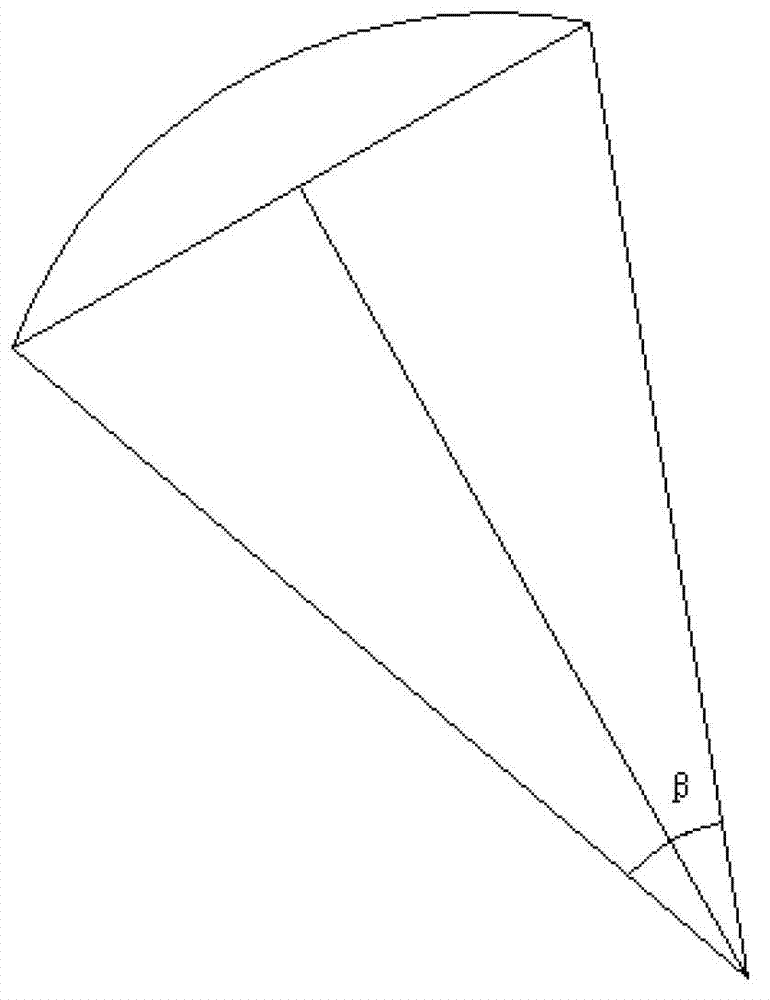

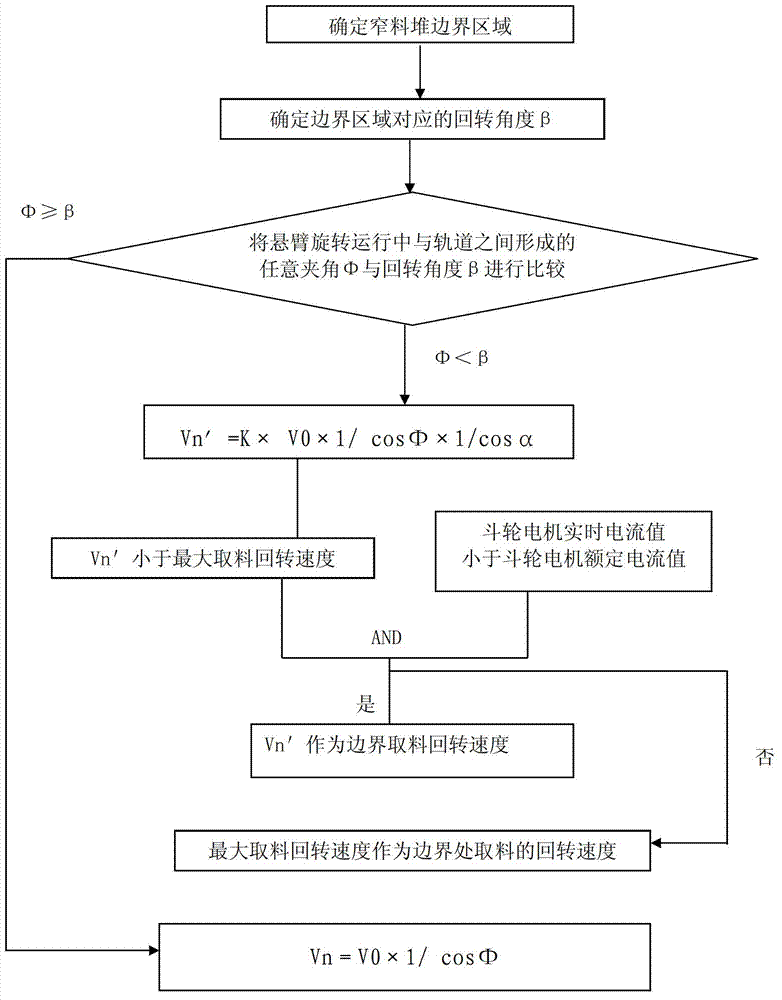

[0027] figure 1 Shown is a schematic diagram of a narrow stockpile, and whether it is a normal stockpile or a narrow stockpile can be judged based on on-site experience. Generally, a stockpile with a stockpiling capacity of less than 5,000 tons and a height greater than 17 meters is regarded as a narrow stockpile. Before the reclaiming operation, the operator determines whether it is a narrower stockpile based on experience. If it is a narrower stockpile, adjust the control mode of the PLC controller to the working mode of the narrower stockpile.

[0028] When the stockpile is narrow, on the side of the smaller angle, rely on the repose angle α of the material to calculate the range of speed regulation that needs to be different from 1 / COSφ on both sides of the material. The smaller the angle of repose, the greater the speed ΔV that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com