Method for preparing multi-level porous channel beta zeolite

A beta zeolite and pore channel technology, which is applied in the field of beta zeolite preparation, can solve the problems of chained active site destruction, uneven crystal size, and wide distribution of mesopore size of titanium silicalite, and achieves the effect of reducing processes and saving raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

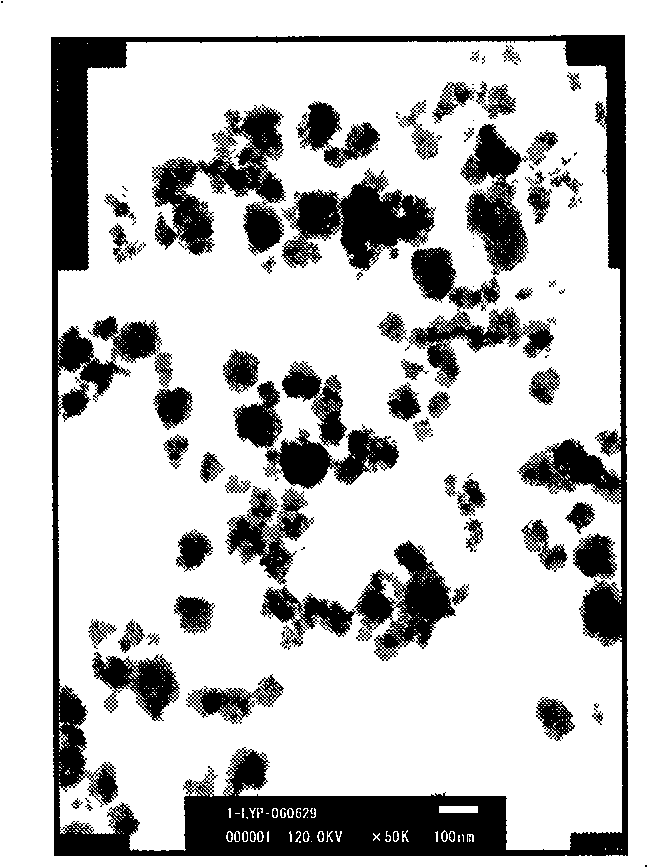

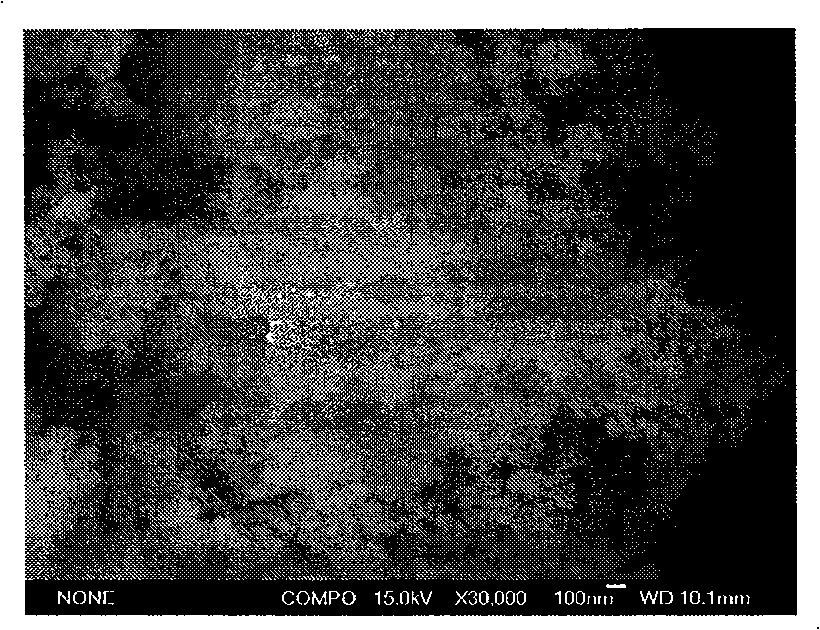

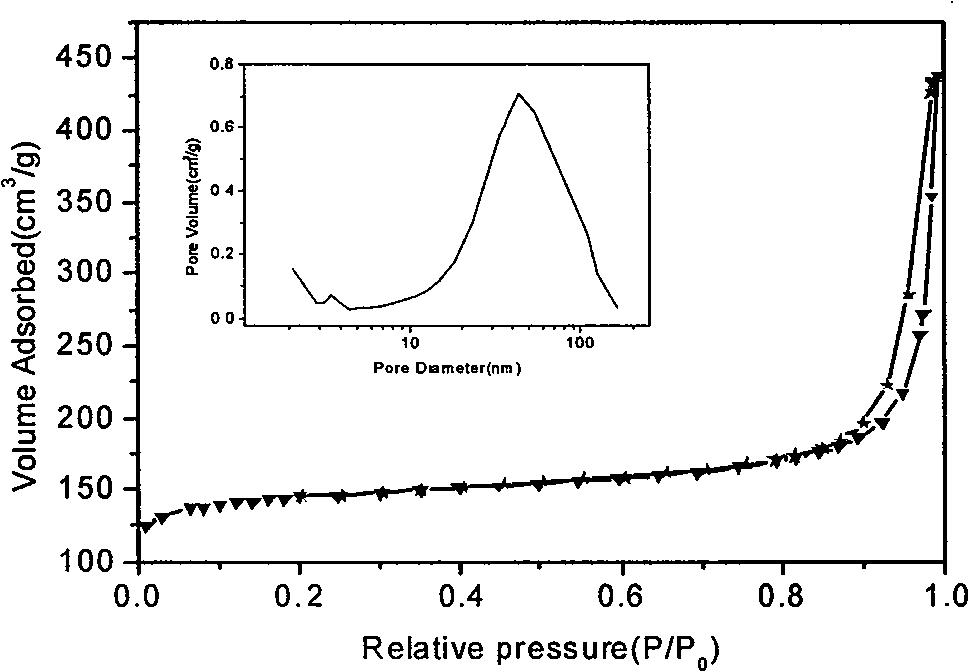

[0035] Take 7.5g MCM-41 (SiO 2 / Al 2 o 3 =25), add phenol and formaldehyde (phenol to formaldehyde molar ratio is 8) by equal volume impregnation method, polymerize 8h in oven at 125 DEG C, the obtained phenolic resin polymer is carbonized under the protection of nitrogen, and the carbonization program is heating rate 2 DEG C / Min was raised from room temperature to 700°C, and then cooled naturally to room temperature at a constant temperature for 5 hours. The resultant was a composite of mesoporous and carbon materials. Take 2 g of the compound and place it in a crucible, add 3.0 g (wt.48%) of tetraethylammonium hydroxide solution, and place it at room temperature for 10 h, then put the crucible into a reaction kettle filled with 5 ml of water, and place it at 170 After crystallization at ℃ for 3 days, the resulting solid was washed with water, filtered, dried at 100 ℃, and calcined at 550 ℃ for 8 hours to obtain a white multi-stage zeolite beta powder, which was designated...

Embodiment approach 2

[0037] Take 7.5g MCM-41 (SiO 2 / Al 2 o 3 =50), add sucrose solution (2.5g sucrose: 0.28g concentrated sulfuric acid: 6.0g water) by equal volume impregnation method, polymerize in oven at 125°C for 8h, the gained polymer is carbonized under nitrogen protection, and the carbonization program is heating rate 2 ℃ / min increased from room temperature to 700 °C, and then cooled naturally to room temperature at a constant temperature for 5 hours. The resultant was a composite of mesoporous and carbon materials. Get this compound 2g and place in the crucible, add 0.096g sodium metaaluminate (wt.41%), 0.68g tetraethylammonium bromide and 2.0g (wt.48%) tetraethylammonium hydroxide Solution, after standing at room temperature for 10 hours, put the crucible into a reaction kettle containing 3ml of water, crystallize at 170°C for 3 days, wash the obtained solid with water, filter, dry at 100°C, and roast at 550°C for 8 hours to obtain a white multi-level channel β Zeolite powder, the pr...

Embodiment approach 3

[0039] Take 6.5g MCM-48 (SiO 2 / Al 2 o 3 =30), add phenol and formaldehyde (phenol to formaldehyde molar ratio is 8) by equal volume impregnation method, polymerize 8h in oven at 125 DEG C, the obtained phenolic resin polymer is carbonized under the protection of nitrogen, and the carbonization program is heating rate 2 DEG C / Min was raised from room temperature to 700°C, and then cooled naturally to room temperature at a constant temperature for 5 hours. The resultant was a composite of mesoporous and carbon materials. Get 2g of the compound and place it in a crucible, add 2.5g (wt.48%) of tetraethylammonium hydroxide solution, leave it at room temperature for 10h, then put the crucible into a reaction kettle filled with 5ml of water, After crystallization at 170°C for 4 days, the resulting solid was washed with water, filtered, dried at 100°C, and calcined at 550°C for 8 hours to obtain a white multi-stage zeolite beta powder, which was designated as M48B-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com