Method for producing insoluble sulfur

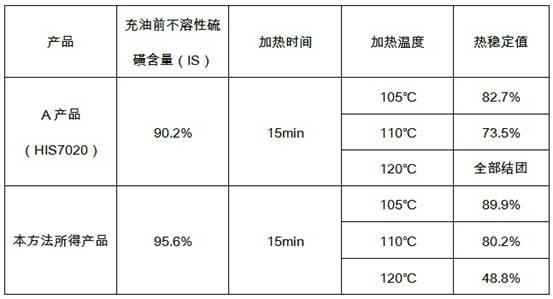

A production method and sulfur technology, applied in the preparation/purification of sulfur, etc., can solve problems such as unfavorable environmental protection, low melting point of products, easy corrosion of equipment, etc., and achieve continuous production, facilitate subsequent processing, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

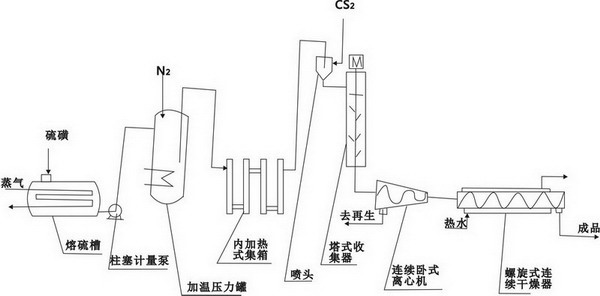

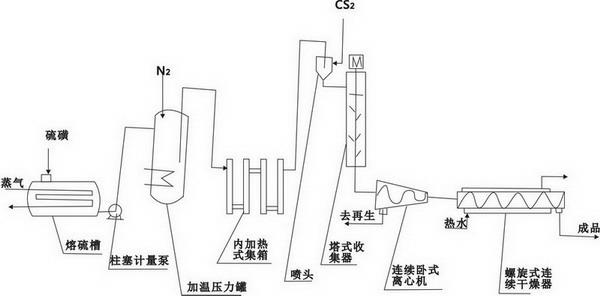

[0024] Such as figure 1 As shown, the solid sulfur is heated and melted in the sulfur melting tank at a temperature of 130°C, and the melted liquid sulfur is pumped into a heated pressure tank with a pressure of 1MPa through a plunger metering pump at a flow rate of 100kg / h for the first stage Heating, continuous heating to 420°C, under N 2 Under pressure, liquid sulfur continuously enters the internal heating header, which is composed of 8 pipe sections with closed ends, and electric heating tubes are inserted inside, which not only ensures safety, but also has higher thermal efficiency. It is 1.2MPa; under its own pressure, the liquid sulfur enters the pressure atomizing nozzle for atomization, and the atomized liquid sulfur and the high-speed rotating CS 2 Mixed cold extraction, the mixed emulsion enters the tower collector, and the tower collector is equipped with a multi-layer agitator to fully mix and dissolve the soluble sulfur. The temperature in the tower collector i...

Embodiment 2

[0026] Such as figure 1 As shown, the solid sulfur is heated and melted in the sulfur melting tank at a temperature of 150°C, and the melted liquid sulfur is pumped into a heated pressure tank with a pressure of 1 MPa through a plunger metering pump at a flow rate of 100 kg / h for the first stage Heating, continuous heating to 430°C, under N 2 Under pressure, liquid sulfur continuously enters the internal heating header, which is composed of 12 pipe sections with closed ends, and electric heating tubes are inserted inside, which not only ensures safety, but also has higher thermal efficiency. 0.8MPa; under its own pressure, the liquid sulfur enters the pressure atomizing nozzle for atomization, and the atomized liquid sulfur and the high-speed rotating CS 2 Mixed cold extraction, the mixed emulsion enters the tower collector, and the tower collector is equipped with a multi-layer agitator to fully mix and dissolve the soluble sulfur. The temperature in the tower collector is k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com