Cleaning agent for automobile

A technology for cleaning agents and vehicles, which is applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc. It can solve the problems of corrosion and discoloration of metal parts, aging of plastic rubber, limited cleaning ability, etc., and achieve good results. Effects of removal, low interfacial tension, and stable solution properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

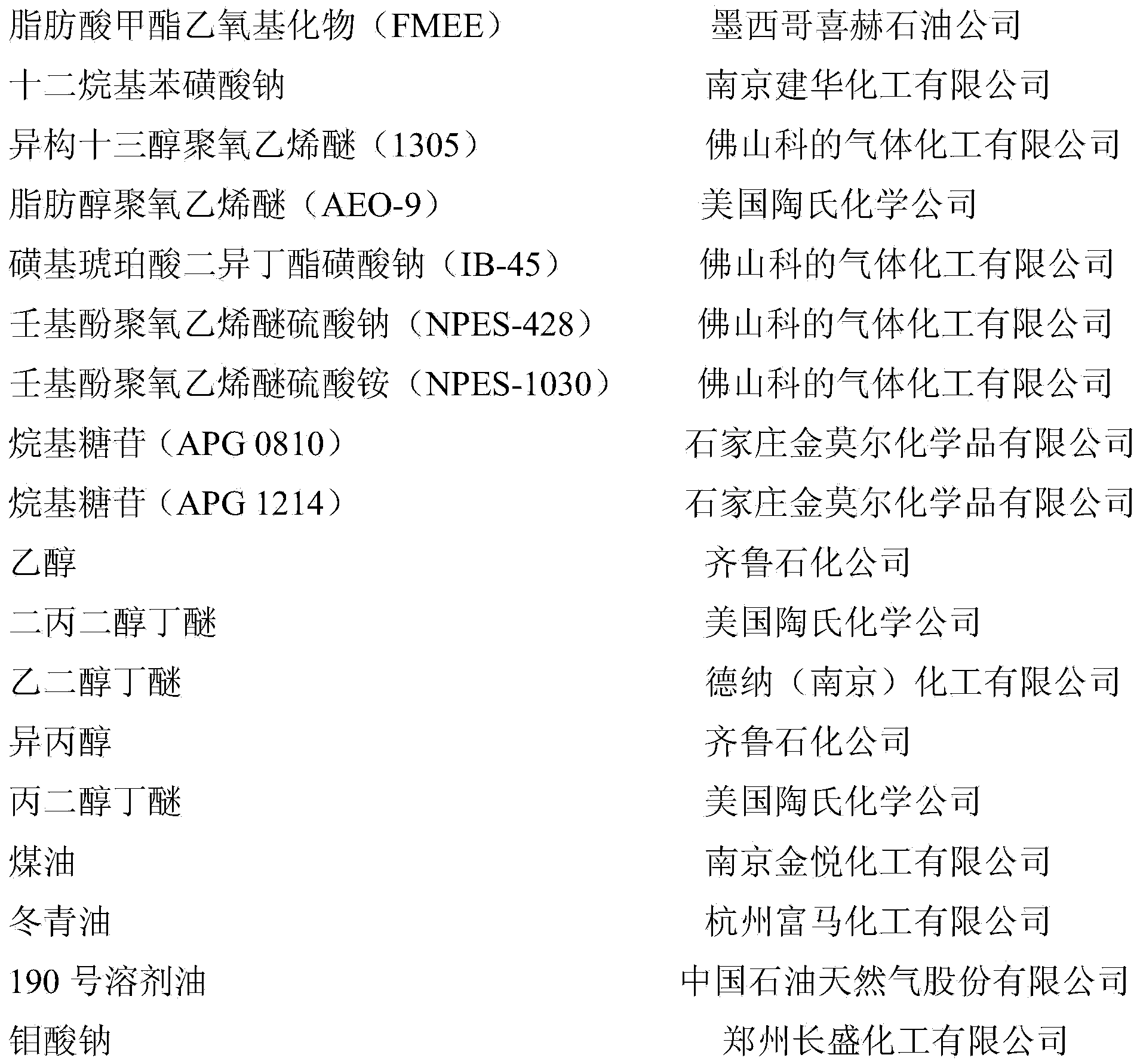

Method used

Image

Examples

preparation example Construction

[0039] A. Preparation of artificial oil stain: Weigh 60g of N32HL hydraulic oil, 30g of industrial vaseline, and 30g of barium petroleum sulfonate, mix and heat the above components to fully melt, stir evenly and store for later use.

[0040] B, preparation of sebum stained cloth:

[0041] Preparation of mixed oil: Weigh 30g of palmitic acid, 15g of stearic acid, 45g of coconut oil, 30g of liquid paraffin, 60g of olive oil, 15g of squalene, 15g of cholesterol, and 45g of cottonoleic acid in a beaker. Stir evenly and store in airtight for later use.

[0042] Preparation of dust, carbon black and dirt: Weigh 2.5g of carbon black in a mortar, add 10mL of ethanol, grind for 10min, add 1g of iron oxide yellow, 2g of iron oxide black, and grind for 10min, add 15mL of distilled water during this process. Add 3.8 g of gum arabic dissolved in 10 mL of distilled water, wash the cup with 5 mL of distilled water, put it into a mortar, and grind for 10 min. Then add 44.5g of clay, add 50...

Embodiment 1

[0065] The mass percentages of each component in a car cleaning agent are as follows:

[0066]

[0067] Adjust the pH value to 9.5 with 20% sodium hydroxide solution, and the balance is water.

[0068] The prepared cleaning agent is tested according to the above method, and the test results are shown in Table 1:

[0069] Table 1

[0070]

[0071] The cleaning effect of this formula is average, but because of the low content or low price of each component, it is economical, and this formula can meet other performance tests except the cleaning rate.

Embodiment 2

[0073] The mass percentages of each component in a car cleaning agent are as follows:

[0074]

[0075] Adjust the pH value to 8.0 with 20% sodium hydroxide solution, and the balance is water.

[0076] The prepared cleaning agent is tested according to the above method, and the test results are shown in Table 2:

[0077] Table 2

[0078]

[0079] The cleaning agent has a good cleaning effect on metals, and has the effect of blackening and brightening rubber after cleaning, but the cleaning effect on fabrics is poor, and other performances are qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com