Method for preparing naphthalene sulphonic acid by sulfonating sulfur trioxide in microreactor

A technology of micro-reactor and sulfur trioxide, which is applied in the fields of sulfonic acid preparation, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve the problems of waste acid polluting the environment, achieve strong heat transfer capacity, and avoid side effects Responsive, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

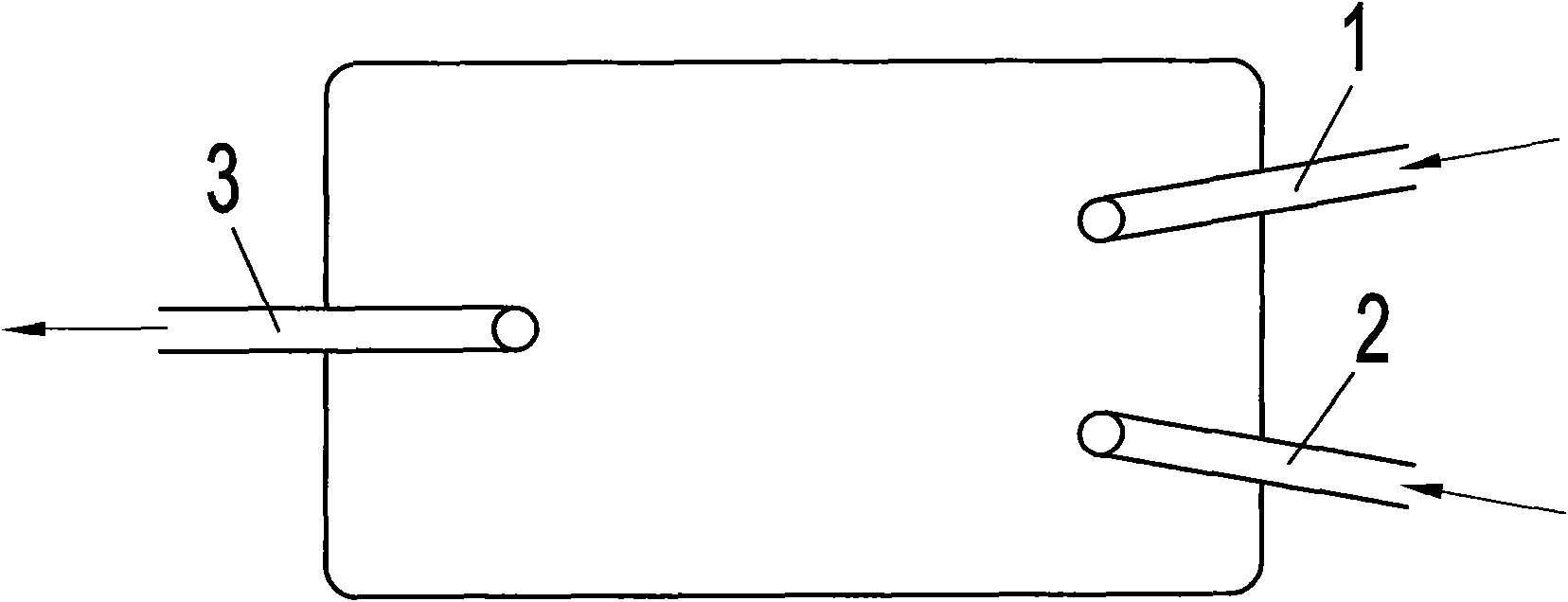

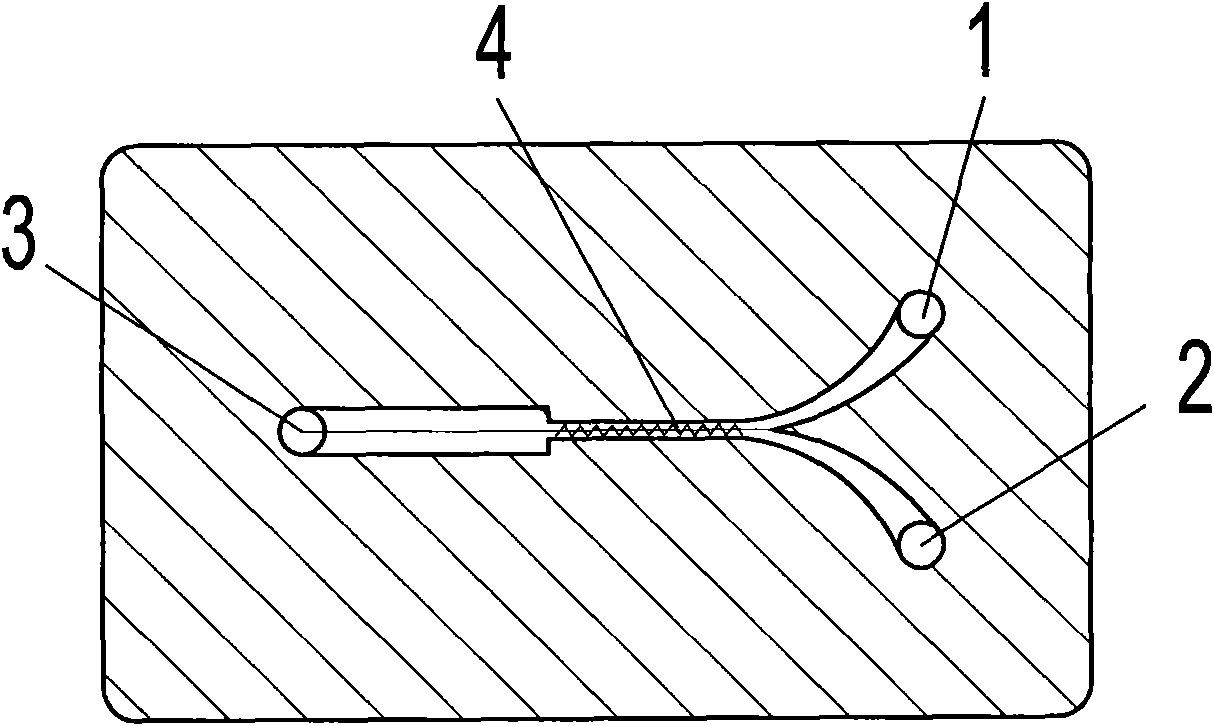

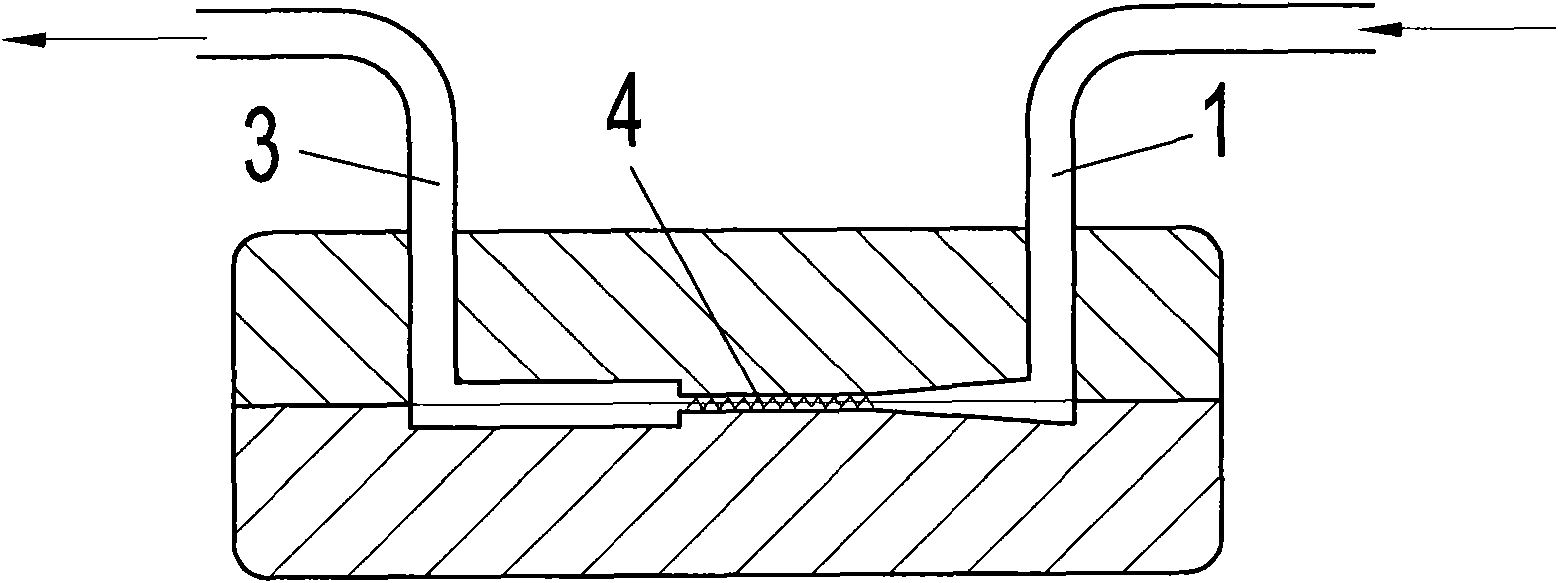

Method used

Image

Examples

Embodiment 1

[0020] Dichloromethane, naphthalene and liquid sulfur trioxide are formulated into sulfur trioxide-dichloromethane solution and naphthalene-dichloromethane solution in molar ratio of 31:1:1 respectively, and the prepared sulfur trioxide-dichloromethane solution is and naphthalene-dichloromethane solution are sent to the corresponding reaction material inlet of the microreactor with a diameter of 10 micron channels at a flow rate of 1 ml / min through a calibrated constant flow pump. The extension channel volume is 1ml. The sulfonation reaction takes place in microreactors and extension channels placed in a constant temperature bath. The reaction temperature was controlled at -17°C. The reaction material at the outlet of the extension channel is passed into water to terminate the reaction. Take the water phase and add 20% sodium chloride for salting out, and the precipitated by-product sodium salt can be filtered off. The filtrate containing free α-naphthalenesulfonic acid is ...

Embodiment 2

[0022] Prepare sulfur trioxide-1,1,2,2-tetrachloroethane solution and naphthalene by mixing 1,1,2,2-tetrachloroethane, naphthalene and liquid sulfur trioxide in a molar ratio of 19:1:1 -1,1,2,2-tetrachloroethane solution, the prepared sulfur trioxide-1,1,2,2-tetrachloroethane solution and naphthalene-1,1,2,2-tetrachloroethane The alkane solution is sent to the corresponding reaction material inlet of the microreactor with a diameter of 200 micron channels at a flow rate of 4ml / min through a calibrated constant flow pump. The extension channel volume is 5ml. The sulfonation reaction takes place in microreactors and extension channels placed in a constant temperature bath. The reaction temperature was controlled at 20°C. The reaction material at the outlet of the extension channel is passed into water to terminate the reaction. Take the water phase and add 20% sodium chloride for salting out, and the precipitated by-product sodium salt can be filtered off. The filtrate conta...

Embodiment 3

[0024] Prepare 1,2-dichloroethane, 2-naphthol and liquid sulfur trioxide in a molar ratio of 50:1:3 to prepare sulfur trioxide-1,2-dichloroethane solution and 2-naphthol-1 , 2-dichloroethane solution, the prepared sulfur trioxide-1,2-dichloroethane solution and 2-naphthol-1,2-dichloroethane solution were calibrated with a constant flow pump at 7ml / The min flow rate is sent to the corresponding reaction material inlet of the microreactor with a channel diameter of 350 microns. The extension channel volume is 8ml. The sulfonation reaction takes place in microreactors and extension channels placed in a constant temperature bath. The reaction temperature was controlled at 50°C. The reaction material at the outlet of the extension channel is passed into water to terminate the reaction. Take the aqueous phase and add 20% potassium chloride for salting out, concentrate, cool, crystallize, filter, wash with water, and dry to obtain an off-white solid product. The product is detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com