Mesoporous spherical alumina prepared by guiding of template and preparation method thereof

A spherical alumina and template technology, which is applied in chemical instruments and methods, alumina/aluminum hydroxide, catalyst carriers, etc., can solve the problems of cumbersome preparation process, high cost, unfavorable mass transfer and reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Dissolve 10 g of aluminum powder with an average particle size of 50 μm in 200 g of hydrochloric acid with a concentration of 5% wt at 95° C. to prepare an aluminum sol with a transparent appearance and Tyndall effect.

[0028] B. Add 1.89g of ammonium acrylate to the above aluminum sol, stir and mix thoroughly. Then 12g of hexamethylenetetramine was added into the sol and fully dissolved.

[0029] C. Drop the sol of step B into vacuum pump oil at 70°C with a No. 7 dispersing dripper, and the height of the oil column is 300cm. The formed pellets were separated from the oil and aged at 130°C for 5 hours.

[0030]D. The obtained product was washed, dried at 140°C for 10 hours, and calcined at 550°C for 4 hours to obtain a spherical alumina carrier.

[0031] It has been determined that the specific surface area of the spherical alumina carrier is 250m 2 / g, the pore volume is 0.89ml / g, and the bulk density is 0.6g / cm 3 , The average particle size is 1.4mm, the cru...

Embodiment 2

[0033] A. Dissolve 30g of aluminum powder with an average particle size of 100 μm in 300g of hydrochloric acid with a concentration of 10%wt to prepare aluminum sol.

[0034] B. Add 8.5g of acrylamide into the aluminum sol and mix thoroughly, then add 35g of hexamethylenetetramine into the sol to fully dissolve.

[0035] C. Use a No. 7 dispersion dropper to drop into 85°C oil for molding, and the height of the oil column is 300cm. The formed pellets were separated from the oil and aged at 130°C for 5 hours.

[0036] D. The obtained product was washed, dried at 150°C for 10 hours, and calcined at 600°C for 4 hours to obtain a spherical alumina carrier.

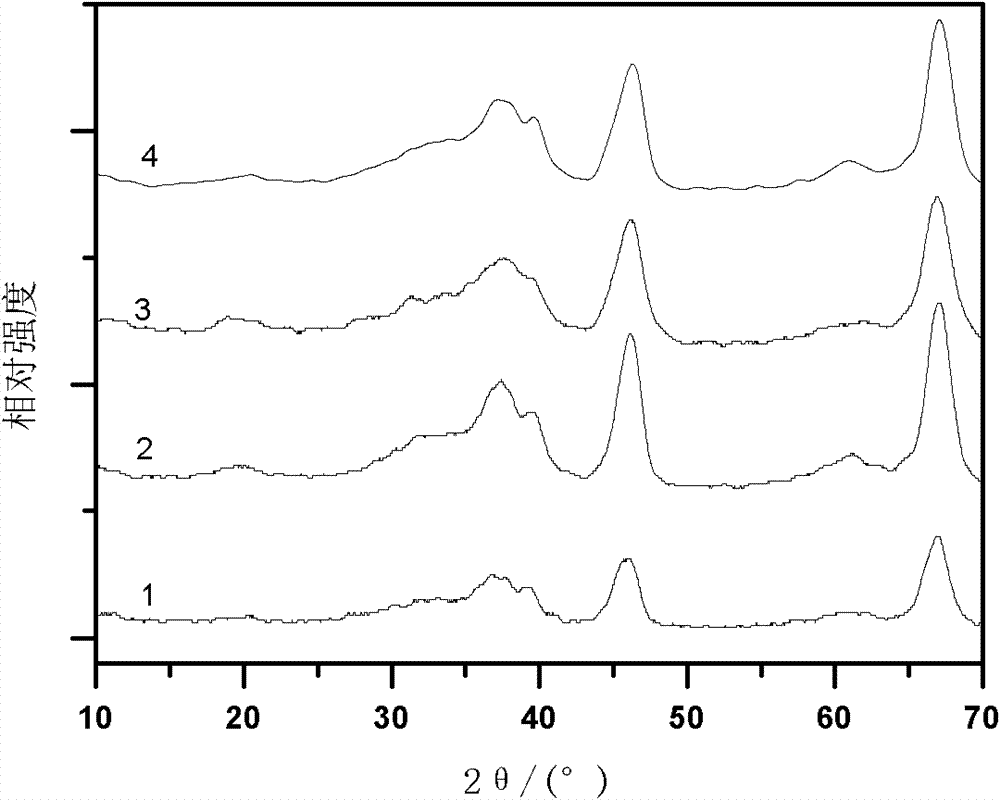

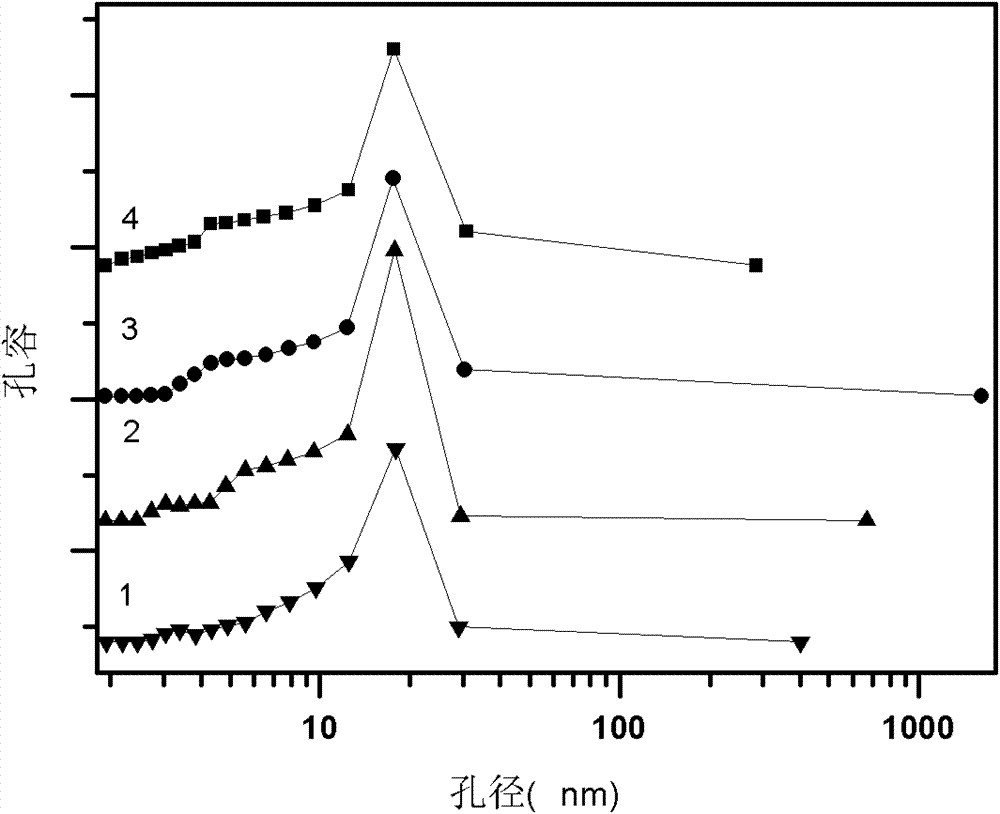

[0037] It has been determined that the specific surface area of the spherical alumina carrier is 231m 2 / g, the pore volume is 0.85ml / g, the bulk density is 0.53g / cm 3 , The average particle size is 1.5mm, the crushing strength is 92.4N / grain, and the average pore size is 17.63nm. XRD pattern see figure 1 Curve 2 in the ...

Embodiment 3

[0039] A. Prepare aluminum sol by dissolving 100 g of aluminum powder with an average particle size of 10 μm in 1000 g of hydrochloric acid with a concentration of 15% wt.

[0040] B. Add 56.6g of polyvinyl alcohol into the aluminum sol to dissolve, then add 115g of hexamethylenetetramine into the sol to fully dissolve.

[0041] C. Use a No. 16 dispersion dropper to drop into 95°C oil for molding, and the height of the oil column is 200cm. The formed pellets were separated from the oil and aged at 130°C for 5 hours.

[0042] D. The obtained product was washed, dried at 70°C for 24 hours, and calcined at 600°C for 4 hours to obtain a spherical alumina carrier.

[0043] It has been determined that the specific surface area of the spherical alumina carrier is 210m 2 / g, the pore volume is 0.95ml / g, the bulk density is 0.52g / cm 3 , The average particle size is 2.1mm, the average crushing strength is 85.8N / grain, and the average pore size is 18.38nm. XRD pattern see figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com