Solid electrolyte for all-solid battery and method of preparing same

A solid electrolyte and all-solid-state battery technology, applied in solid electrolytes, electrolytes, battery electrodes, etc., can solve the problems of high material cost, increase battery area, etc., and achieve the effect of safe and cheap preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

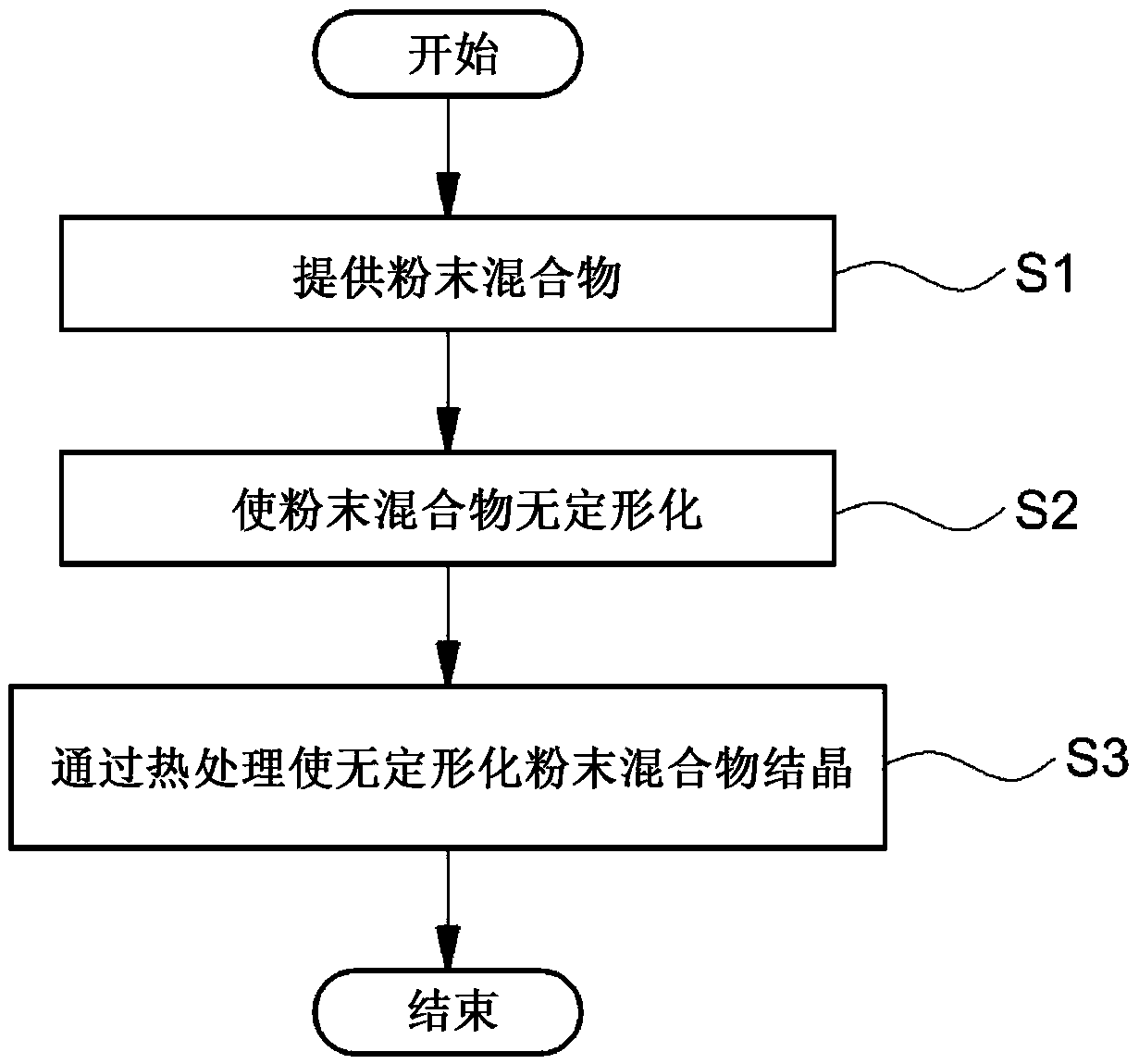

[0085] (S1) By mixing sulfur elemental powder (manufactured by Sigma Aldrich, sulfur), phosphorus elemental powder (manufactured by SigmaAldrich, phosphorus), lithium elemental powder (manufactured by FMC, lithium powder), and lithium chloride powder (manufactured by Sigma Aldrich, LiCl) to obtain a powder mixture.

[0086] Specifically, 11.9 g of sulfur elemental powder, 2.3 g of phosphorus elemental powder, 2.6 g of lithium elemental powder, and 3.1 g of lithium chloride were weighed and mixed to obtain a powder mixture. The molar ratio of raw materials is Li:P:S:LiCl=5:1:5:1.

[0087] (S2) The powder mixture was mixed with 165g of xylene solvent, and then placed in a planetary ball mill together with 1150g of zirconia balls. Thereafter, milling was performed at about 360 RPM, thereby amorphizing the powder mixture.

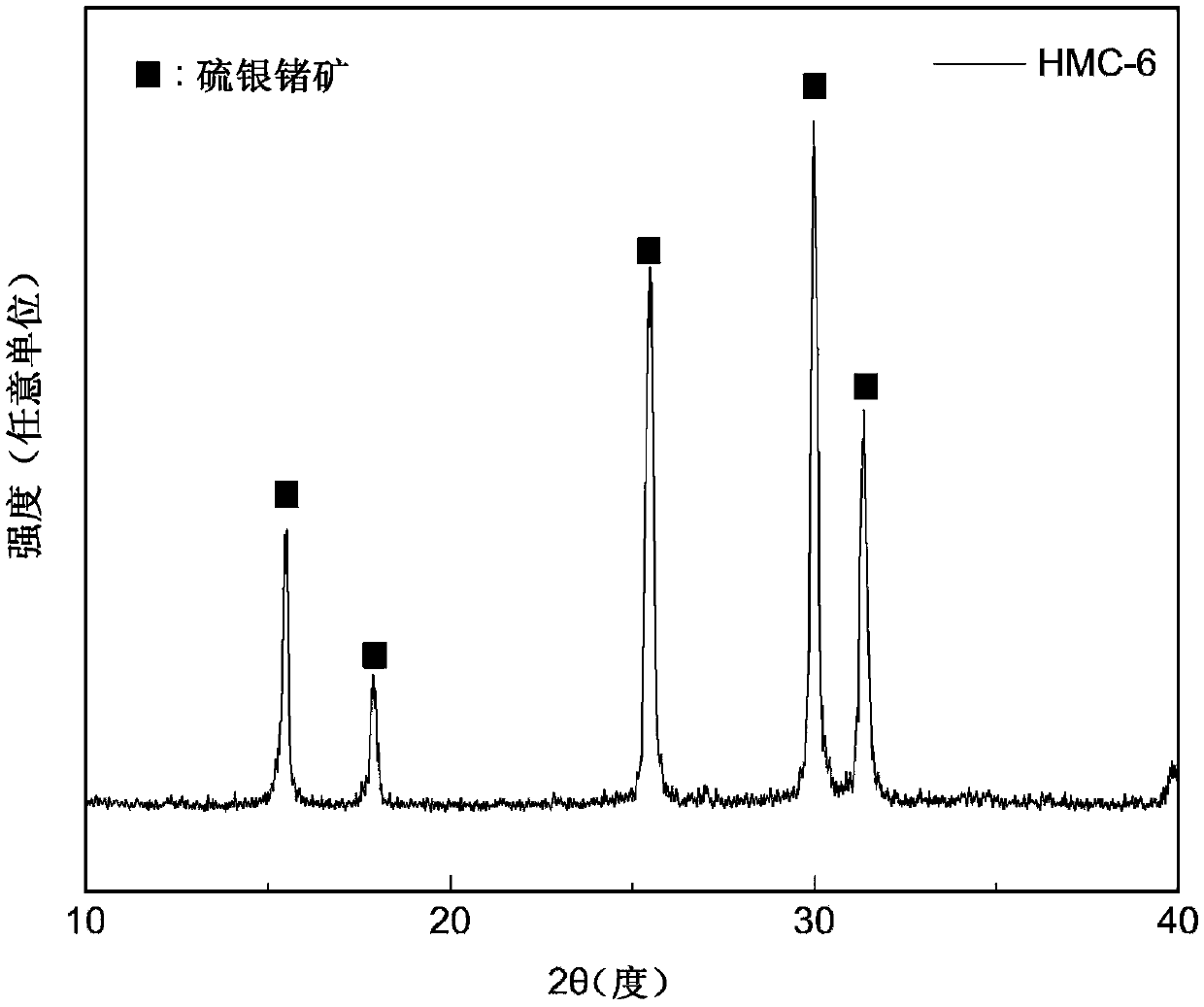

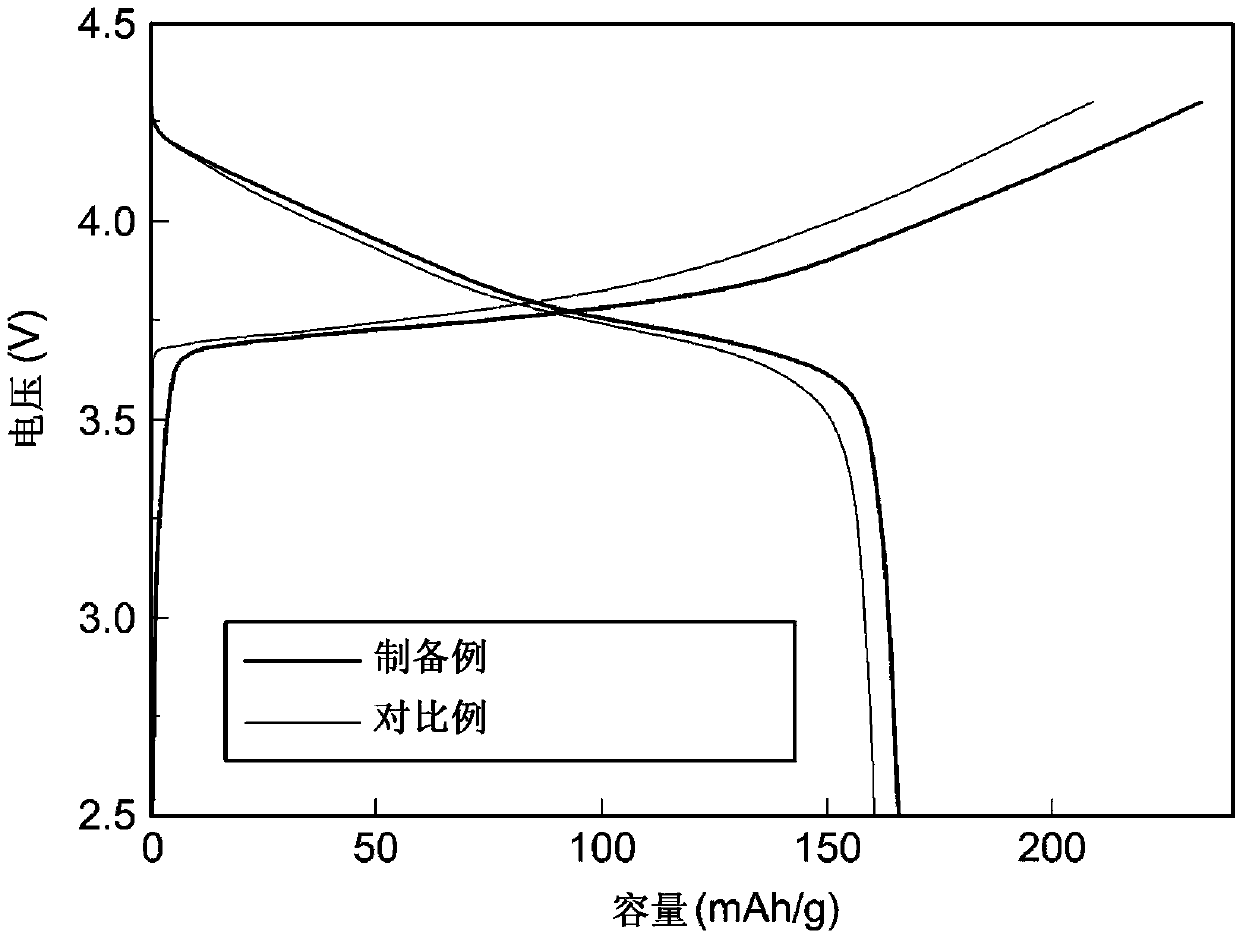

[0088] (S3) The amorphized powder mixture was crystallized by heat treatment at a temperature of about 500° C. for 4 h, thereby producing a solid electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com