A method for preparing ethylenediamine by using ethanolamine and ammonia as raw materials

A technology of ethanolamine and ethylenediamine, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of serious corrosion, large sodium chloride, large energy consumption, etc., and achieves improved selectivity, reduced The effect of reaction pressure and energy consumption, flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

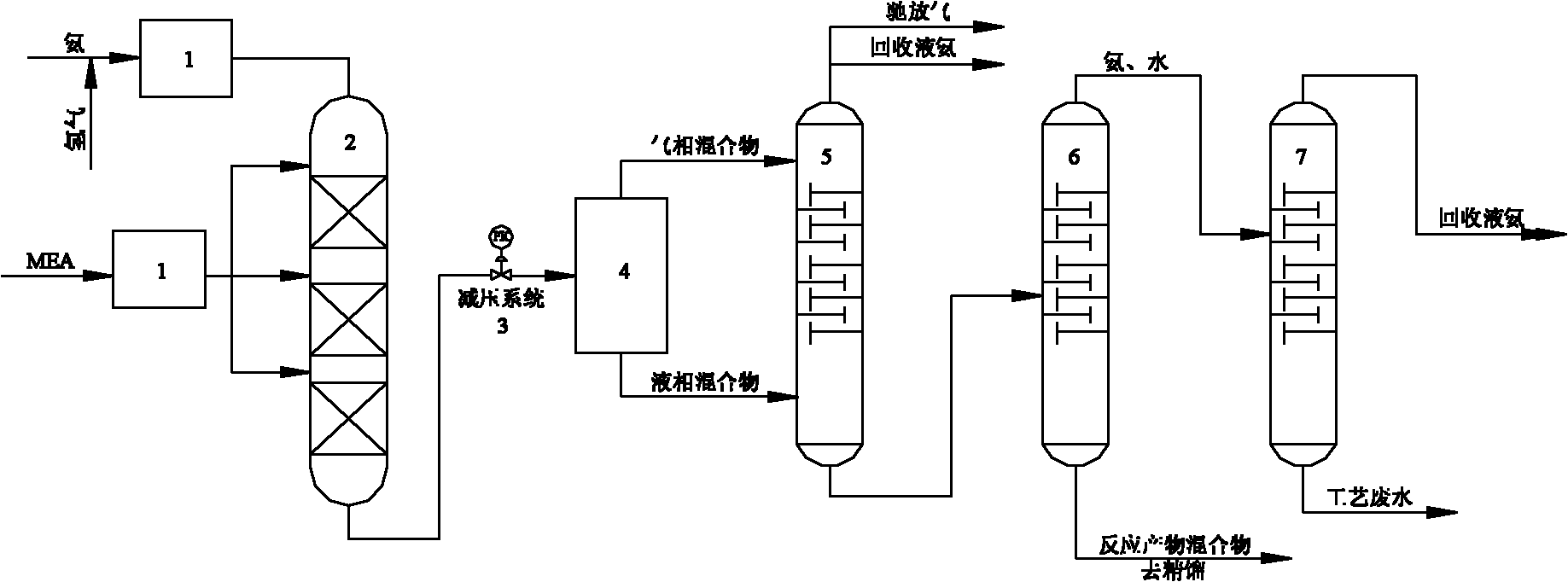

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] figure 1 Be an embodiment of the present invention, the device that adopts comprises raw material heater (1), is used for the reactor (2) of ammoniation reaction, decompression control valve (3), gas-liquid separator (4), is used for deamination A rectification tower (5), a rectification tower (6) for ammonia stripping and a rectification tower (7) for ammonia recovery; the reactor (2) for ammoniation contains raw material inlet and The reactant outlet; the gas-liquid separator (4) contains a gas-phase outlet and a liquid-phase outlet; the rectifying tower for deammonization has a gas-phase reactant and a liquid-phase reactant inlet, an ammonia outlet, and a reaction product outlet; The rectification tower (6) and the rectification tower (7) used for ammonia recovery contain a reaction liquid inlet, a process waste water outlet, a react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com