Plate-heat-exchanger mist elimination module and cooling tower with same

A cooling tower and anti-fog technology, applied in the field of cooling towers, can solve the problems of circulating water loss, heat exchange failure, and low heat exchange efficiency, and achieve the effect of improving heat exchange efficiency and dispersing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

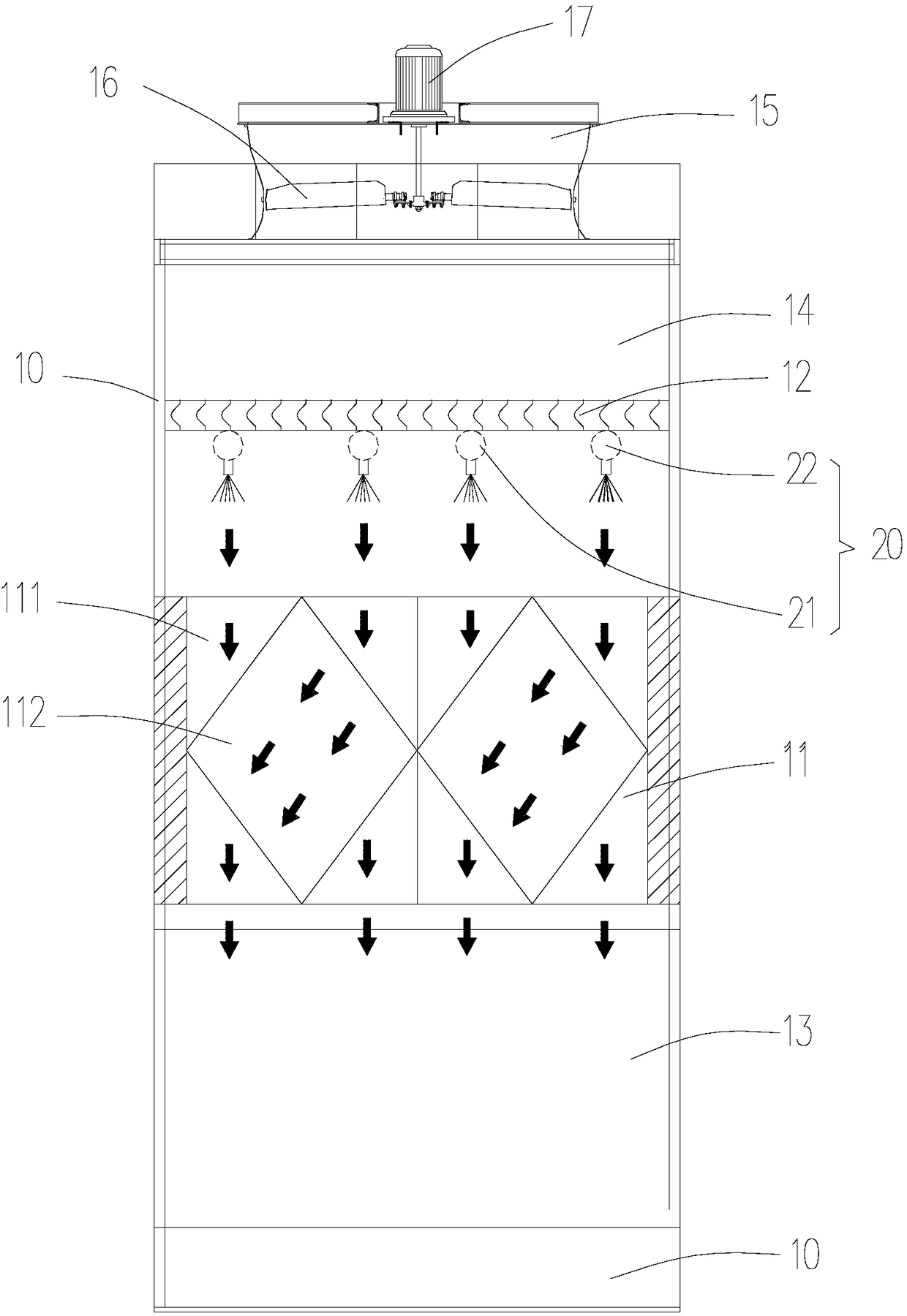

[0020] like figure 1 As shown, the present invention provides a cooling tower with a plate-replacing anti-fog module. Turning on the anti-fog mode in winter can greatly reduce the rain and fog at the outlet of the cooling tower; Thermal effect, you can turn on the anti-fog mode.

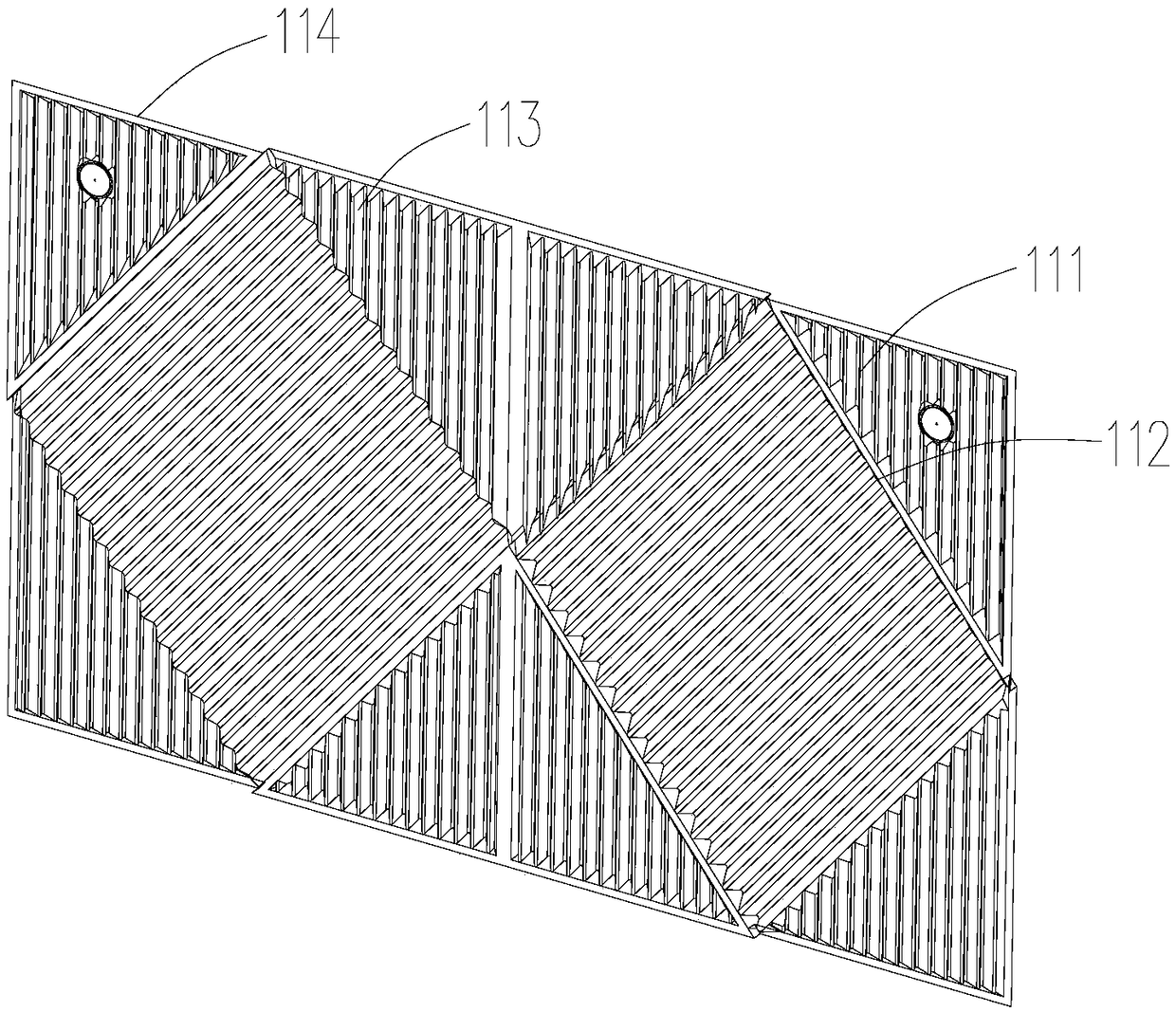

[0021] The fog-eliminating cooling tower of the present invention includes a tower body 10 , a water distribution system 20 , a water pool 30 arranged below the tower body 10 , and a fog-eliminating module 11 and a water eliminator 12 arranged inside the tower body 10 .

[0022] The tower body 10 is roughly in the shape of a cylindrical structure with two ends open, and the pool 30 is arranged at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com