Method for producing polymer grade ethylene glycol and co-producing methyl glycolate

A technology of methyl glycolate and ethylene glycol, which is applied in the preparation of carboxylate, the production of bulk chemicals, chemical instruments and methods, etc., can solve the problems of shortening life, increasing the difficulty of product separation and purification, catalyst poisoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

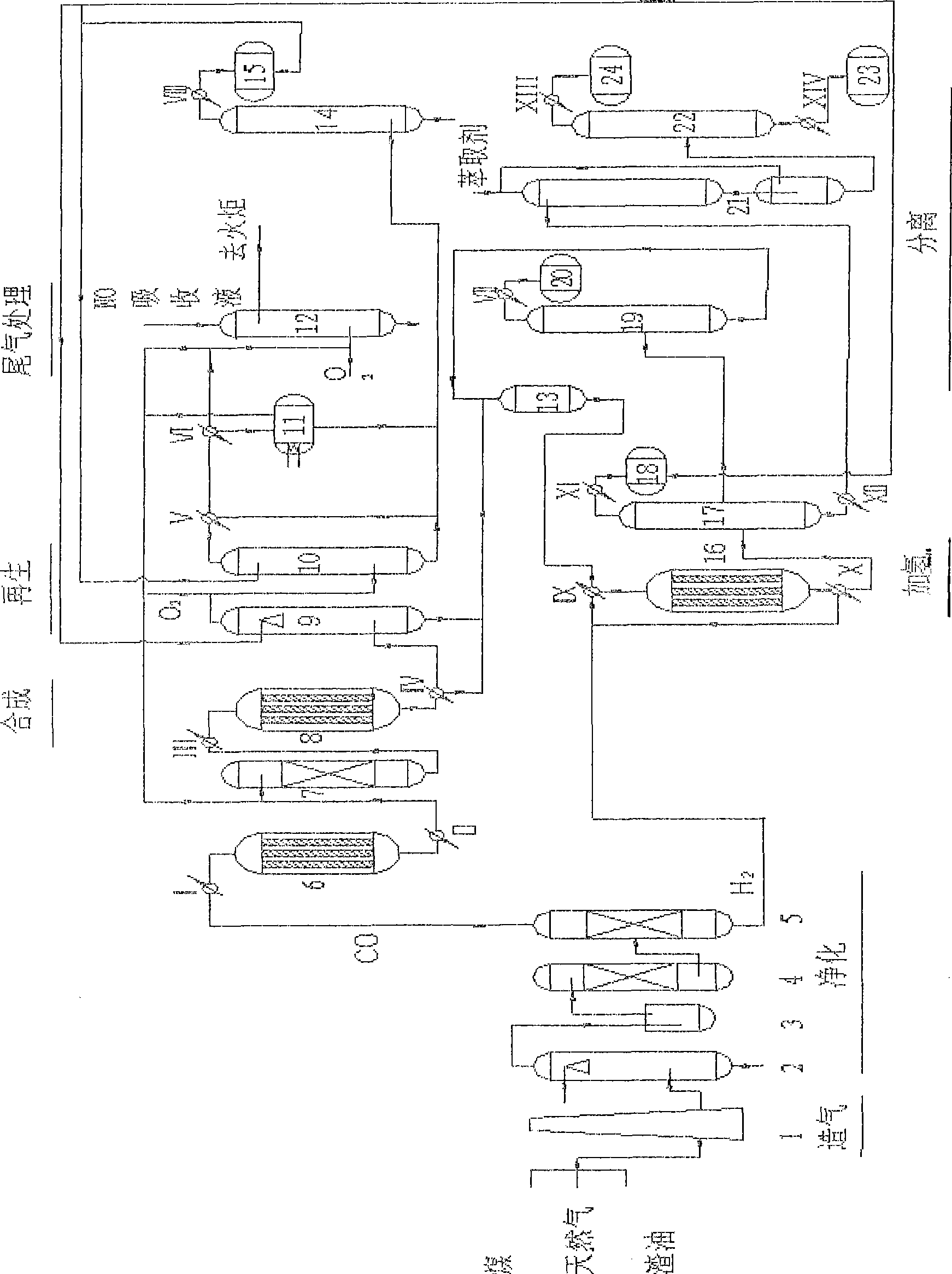

[0063] 1. Preparation of gas raw materials: First, coal, natural gas or residual oil are used as raw materials to produce raw material gas, and the synthesis gas from the gasifier 1 is subjected to dust removal 2, wet desulfurization 3, fine desulfurization 4 to remove residual organic matter in the gas source Sulfur and inorganic sulfur, so that the total sulfur volume content -6 , the desulfurized gas is separated by PSA pressure swing adsorption 5 to obtain CO ≥ 98.5% and H 2 ≥99% gas, press O in CO 2 / H 2 = 0.6-0.9 volume ratio is mixed with oxygen, and the oxygen-added CO is heated to 100-250°C by the preheater I, and enters the dehydrogenation reactor 6 to remove the H in the CO 2 , H in CO after dehydrogenation 2 Volume content -6 , O 2 -6 , CO loss <0.3% during dehydrogenation.

[0064] 2. Carbonylation of dimethyl oxalate: the gas after dehydrogenation and the CH from the methyl nitrite storage tank 11 3 The uncondensed gas from ONO and condenser VI is mixed and ...

Embodiment 1

[0072] Production process using coal as raw material:

[0073] Synthesis gas produced from coal as raw material by atmospheric pressure method, its volume percentage is 28% CO, 55% H 2 , 10% N 2 , 5%CO 2 , 1% CH 4 , 0.5% Ar, 0.2% O 2 , water washing dust removal, wet desulfurization, fine desulfurization to remove residual organic sulfur and inorganic sulfur in the gas source, so that the total sulfur content is -6 , and then go to PSA to separate CO and H 2 , the volume content of CO after separation is 98.5%, H 2 The volume content is 99%; then the dimethyl oxalate synthesis and dimethyl oxalate hydrogenation sections are respectively removed. H in CO 2 The volume content is 1%, and 0.6% volume of oxygen is added to the dehydrogenation reactor for dehydrogenation. The dehydrogenation catalyst is to dissolve 5 grams of magnesium nitrate and 6 grams of zinc nitrate in 70 grams of water, and then pour into 100 grams of aluminum oxide In the beaker of the carrier, dry aft...

Embodiment 2

[0075] Production process using natural gas as raw material:

[0076] Synthesis gas produced by conversion of natural gas to pure oxygen, its volume percentage is composed of 26% CO, 60% H 2 , 2%N 2 , 10% CO 2 , 1.5%CH 4 , 0.4% Ar, 0.1% O 2 , because natural gas has been pretreated, the raw material is relatively pure, after fine desulfurization, it is directly sent to pressure swing adsorption to separate CO and H 2 , the volume content of CO after separation is 98.5%, H 2 The volume content is 99%; then the dimethyl oxalate synthesis and dimethyl oxalate hydrogenation sections are respectively removed. H in CO 2 The volume content is 1.5%, is equipped with the oxygen of 0.9% volume and goes dehydrogenation reactor dehydrogenation, and dehydrogenation catalyst is that 3 gram ferric nitrate, 10 gram ammonium metavanadate and 6 gram cerium nitrate are dissolved in 80 gram water, then pour Put it into a beaker with 100 grams of alumina carrier, dry it after immersion, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com