Ultrahigh-power graphite electrode and preparation method thereof

A graphite electrode and power technology, which is applied in the field of ultra-high-power graphite electrodes and their preparation, can solve the problems of low flexural strength of ultra-high-power graphite electrodes, insufficient physical and chemical indicators, and low hardness of graphite electrodes, so as to improve the hardness, The effect of improving electrical conductivity and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An ultra-high power graphite electrode, including graphite powder, modified pitch, ferric oxide, carbon fiber and needle coke, the composition ratio of the above raw materials is: graphite powder 25%, modified pitch 25%, ferric oxide 2%, carbon fiber 3% and needle coke 45%.

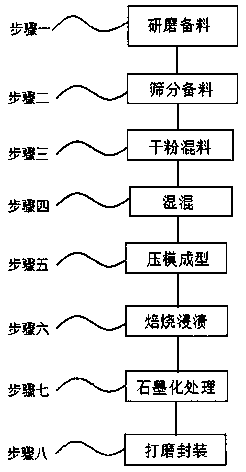

[0024] A method for preparing an ultra-high-power graphite electrode, comprising the following steps: Step 1, grinding and preparing materials; Step 2, screening and preparing materials; Step 3, dry powder mixing; Step 4, wet mixing; Step 5, compression molding; Step 6 , roasting and impregnation; step seven, graphitization treatment; step eight, polishing and encapsulation;

[0025] Wherein in above-mentioned step 1, use ball mill, ferric oxide, carbon fiber and needle coke are ground respectively, after grinding, use sieve to carry out sieving, guarantee that ferric oxide, carbon fiber and needle coke particle diameter are 0.3~0.5mm, carbon fiber is a semi-finished product that has been carboniz...

Embodiment 2

[0034] An ultra-high power graphite electrode, including graphite powder, modified pitch, ferric oxide, carbon fiber and needle coke, the composition ratio of the above raw materials is: graphite powder 30%, modified pitch 25%, ferric oxide 2%, carbon fiber 3% and needle coke 40%.

[0035] A method for preparing an ultra-high-power graphite electrode, comprising the following steps: Step 1, grinding and preparing materials; Step 2, screening and preparing materials; Step 3, dry powder mixing; Step 4, wet mixing; Step 5, compression molding; Step 6 , roasting and impregnation; step seven, graphitization treatment; step eight, polishing and encapsulation;

[0036] Wherein in above-mentioned step 1, use ball mill, ferric oxide, carbon fiber and needle coke are ground respectively, after grinding, use sieve to carry out sieving, guarantee that ferric oxide, carbon fiber and needle coke particle diameter are 0.3~0.5mm, carbon fiber is a semi-finished product that has been carboniz...

Embodiment 3

[0045] An ultra-high power graphite electrode, including graphite powder, modified pitch, ferric oxide, carbon fiber and needle coke, the composition ratio of the above raw materials is: graphite powder 35%, modified pitch 25%, ferric oxide 2%, carbon fiber 3% and needle coke 35%.

[0046] A method for preparing an ultra-high-power graphite electrode, comprising the following steps: Step 1, grinding and preparing materials; Step 2, screening and preparing materials; Step 3, dry powder mixing; Step 4, wet mixing; Step 5, compression molding; Step 6 , roasting and impregnation; step seven, graphitization treatment; step eight, polishing and encapsulation;

[0047] Wherein in above-mentioned step 1, use ball mill, ferric oxide, carbon fiber and needle coke are ground respectively, after grinding, use sieve to carry out sieving, guarantee that ferric oxide, carbon fiber and needle coke particle diameter are 0.3~0.5mm, carbon fiber is a semi-finished product that has been carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com