Time-temperature indicator and preparation method thereof

A label and time technology, applied in the measurement of color/spectral characteristics, etc., can solve the problems of large-scale production and use of unfavorable products, and achieve the effect of good compatibility, expansion of application scope, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

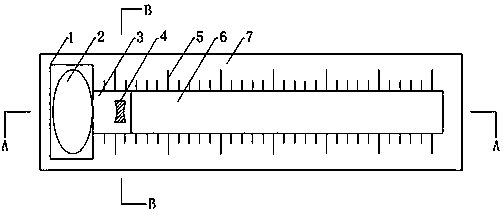

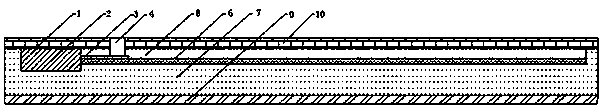

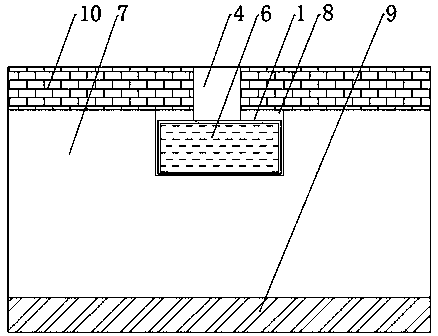

[0043] Measure petroleum jelly, vegetable oil, and glyceryl behenate in a ratio of 70:30:4, add a small amount of colorant corn yellow, heat and mix at a temperature of 60-80°C, and put it into the film storage bag 1 To seal it, place the diffusion medium 6 strip with one end embedded with the thorn piece 3 in the fixing slot 8, and finally assemble the other components one by one to make a time-temperature indicator label. Wherein, the diffusion medium belt 6 is a medium-speed filter paper strip with a specification of 8.0 cm×0.5 cm. When in use, treat at a low temperature below -5°C for 10 minutes, and then push the spines 3 into the film liquid storage bag 1 completely.

[0044] At 9.0°C, the diffusion rate of the time-temperature indicator label of this embodiment is 1.39×10 -2 cm / h. When the time-temperature indicates that the diffusion length of the label is 1.0 cm, it means that 72 hours have passed at 9.0°C. The time-temperature indicator label is able to accurately...

Embodiment 2

[0046] Measure petroleum jelly, vegetable oil, and glyceryl docosanoate at a ratio of 70:30:8, add a small amount of colorant maize yellow, heat and mix at 60-80°C and put it into a film storage bag 1. Inner seal, place the diffusion medium 6 with one end embedded with the thorn piece 3 in the fixed slot 8, and finally assemble the other components one by one to make a time-temperature indicator label. Wherein, the diffusion medium belt 6 is a medium-speed filter paper strip with a specification of 8.0 cm×0.5 cm. When in use, treat at a low temperature below -5°C for 10 minutes, and then push the spines 3 into the film liquid storage bag 1 completely.

[0047] At 10.0°C, the diffusion rate of the time-temperature indicator label of this embodiment is 7.47×10 -3 cm / h. When the time-temperature indicator label has a diffusion length of 0.5 cm, it means that 70 hours have passed at 10.0° C. The time-temperature indicator label of Example 2 can accurately measure the diffusion ...

Embodiment 3

[0049] Measure petroleum jelly, vegetable oil, and glyceryl behenate at a ratio of 70:30:1, add a small amount of colorant capsanthin, heat and mix at a temperature of 60-80°C and put it into the film storage bag 1 To seal it, place the diffusion medium 6 strip with one end embedded with the thorn piece 3 in the fixing slot 8, and finally assemble the other components one by one to make a time-temperature indicator label. Wherein, the diffusion medium belt 6 is a medium-speed filter paper strip with a specification of 8.0 cm×0.5 cm. When in use, treat at a low temperature below -5°C for 10 minutes, and then push the spines 3 into the film liquid storage bag 1 completely.

[0050] At 5.5°C, the diffusion rate of the time-temperature indicator label of this embodiment is 2.58×10 -2 cm / h. When the time-temperature indicates that the diffusion length of the label is 2.0 cm, it means that 77 hours have passed at 5.5°C. The time-temperature indicator label of Example 3 can accura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com