Time-temperature indicator system I

A technology of temperature indicator and time, applied in the field of assembly, can solve the problem of inaccurate prediction of storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

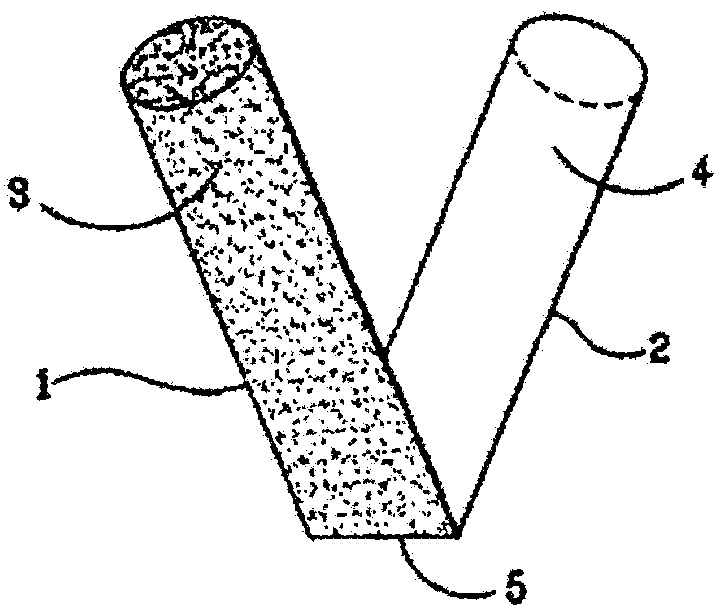

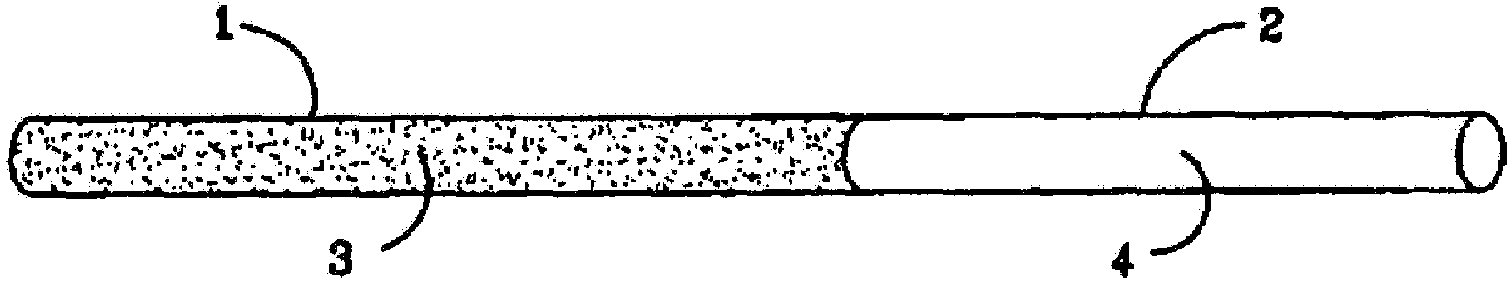

[0164] Time-Temperature Indicator System A

[0165] Gelatin from fish

[0166] Prepare each content to be contained in the first compartment (gel-strip)

[0167] 54g of 22% HiPure fish gelatin (Norland Products Inc., USA) was dissolved in 46g of water which had been preheated to a temperature of about 65°C. Sodium hydroxide was then added until a pH of about 8 was reached. Subsequently, 2 g of type B-gelatin (Sigma), 5 g of trehalose (Sigma) and 2 g of 1% by weight i-carrageenan (Sigma) were included, and the mixture was stirred for about 10 minutes.

[0168] First base component: HiPure fish gelatin.

[0169] Second Matrix Component: Type B - Gelatin.

[0170] Immobilized reagent = i-carrageenan.

[0171] Prepare the contents to be contained in the second compartment (reservoir)

[0172] 2.5 g of methylene blue (Sigma) were dissolved in 73 g of water which had been preheated to a temperature of about 90°C. The mixture was then stirred for about 10 minutes. 5 g Typ...

Embodiment 2a

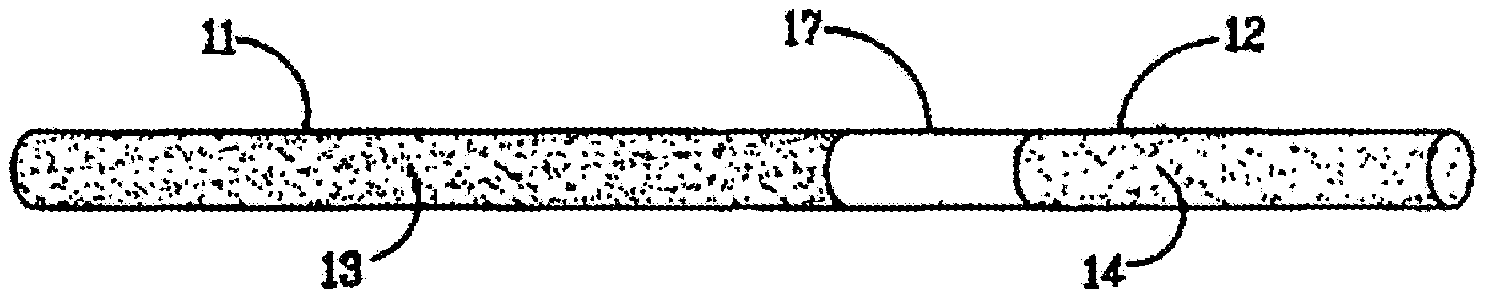

[0182] Time-temperature indicator system B

[0183] "Fish Source Gelatin"

[0184] Prepare the contents to be included in the first compartment (gel-strip)

[0185] 2,5 g of gelatin, Type A (Sigma) and 11,06 g of fish gelatin (Hi Pure Fish Gelatin, Norland Products) were added to 20 ml of hot water and allowed to dissolve. Dissolve 5,0 g Trehalose, Sigma. Add the compound to be immobilized by pipetting 1,75 ml of 1,0 M CuSO4 solution. The volume was adjusted to 50ml with hot water.

[0186] First base component: HiPure fish-derived gelatin.

[0187] Second matrix component: Type A - Gelatin.

[0188] Immobilized reagent = CuSO4.

[0189] Prepare the contents to be contained in the second compartment (reservoir)

[0190]11,06 g of fish gelatin (HiPure fish gelatin, Norland Products) and 5,0 g of trehalose (Sigma) were added to 20 ml of hot water. To the solution was added 8,45 g of K as a mobile compound 4 Hexacyanoferrate (Merck), then diluted with hot water to 50...

Embodiment 2b

[0201] Time-temperature indicator system B

[0202] "Non-Fish Gelatin"

[0203] Prepare the contents to be included in the first compartment (gel-strip)

[0204] To 20 ml of hot water, 2,5 g of gelatin, type A (Sigma) and 5,0 g of trehalose (Trehalsose, Sigma) were added and allowed to dissolve. Add the compound to be immobilized by pipetting 1,75 ml of a 1,0 M CuSO4 solution. The volume was adjusted to 50ml with hot water.

[0205] First Matrix Component: Type A - Gelatin

[0206] Immobilized reagent = CuSO4.

[0207] Prepare the contents to be contained in the second compartment (reservoir)

[0208] 11,06 g of fish gelatin (HiPure fish gelatin, Norland Products) and 5,0 g of trehalose (Sigma) were added to 20 ml of hot water. To the solution was added 8,45 g of K as a mobile compound 4 Hexacyanoferrate (Merck), then diluted with hot water to 50 ml of solution.

[0209] First base component: HiPure fish-derived gelatin.

[0210] Mobile reagent = K 4 Hexacyanofer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com