Time-temperature indicators

A technology of indicators and objects, applied in the field of temperature indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1. Wax composition

[0066] Prepared by combining paraffin wax (product number BA693) from Walker Ceramics, Victoria Australia; liquid paraffin (product number 76233) CAS [8002-72-2] from Fluka and a commercially available candle wax dye and test wax compositions.

[0067] The melting point of solid paraffin was determined to be 58-62°C.

[0068] The mixture of wax and dye is combined and mixed together at a temperature above the melting point of the highest component and solidifies before the approximate melting point is determined. The dye contains 0.5-1.0 wt% of the mixture. Approximate melting points were determined visually using an oven and the results are listed in Table 1 below.

[0069] Table 1. Wax compositions and approximate melting points

[0070] Solid wax Wt%

Liquid wax Wt%

note

15

85

31

colorless

20

80

39

colorless

25

75

40

blue ...

Embodiment 2

[0073] Example 2. Dye Compositions

[0074] Various candle dyes are used to color paraffin wax. The colors used are red, yellow and blue. Wax compositions containing 0.5-1.0 wt% candle dye were observed to have a melting point of -1-3°C higher than wax compositions without the dye. It is believed that this simply reflects the higher melting point of the wax base of the dye material.

[0075] A mixture of dyes was added to the wax composition and it was observed that the mixture of colored dyes could be used to provide a variety of different colors. Red and yellow dyes provide orange wax compositions. Similarly, blue and red dyes produce purple wax compositions, and blue and yellow produce green wax compositions.

Embodiment 3

[0076] Example 3. Visible Thermal History Indicators

[0077] A series of experiments were performed to investigate the properties of the waxes when heated above their melting temperature.

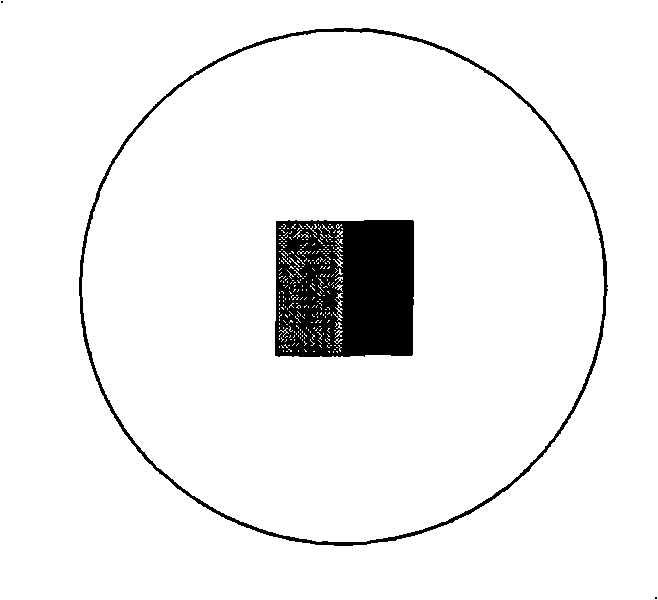

[0078] refer to figure 1 , in a 60mm diameter glass Petrie dish, place a strip of yellow wax (indicated by hashes) and blue wax (indicated by solid black) to a depth of approximately 1mm. The sides of the two wax strips touch each other. Molten colorless wax having a melting point higher than the two colored waxes was added to the dish and surrounded the colored wax strips and allowed to cool and solidify prior to testing.

[0079] Heat the plate and wax in an oven at a temperature above the melting point of the colored wax but below the melting point of the colorless wax for one hour, then cool.

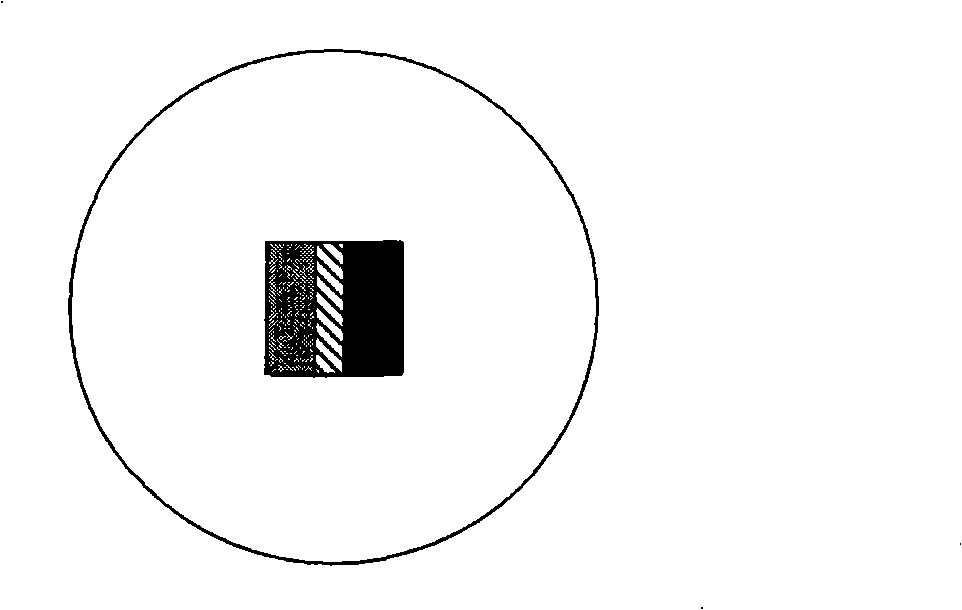

[0080] exist figure 2 The heating result is displayed in . It was found that the initial color wax mixed in the area close to the contact area of the two bars. The central region (rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com