High flow, hydrogenated styrene-butadiene-styrene block copolymer and applications

a technology of hydrogenated styrene and styrene, which is applied in the direction of film/foil adhesives, braids, knotting, etc., can solve the problems of restricted techniques, achieve high flow, improve strength, toughness and elasticity, and reduce the transmission rate of moisture vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

High Melt Flow hSBS Polymer

[0054]hSBS: 201 kg Cyclohexane and 9.1 kg styrene were charged to an 80 gal stainless steel reactor at about 50° C. 2428 mL of about 12 wt. % s-butyllithium were then charged to the reactor to initiate polymerization. The styrene polymerization was allowed to proceed at about 50° C. until completion and a sample was collected for GPC. The molecular weight at this step was determined to be 4.8 kg / mole. An additional 0.38 kg of styrene was added and allowed to polymerize. GPC analysis of this polymer indicated that the molecular weight was 5.0 kg / mole. Butadiene was added at a rate of about 1 kg / min. Within less than a minute of starting the butadiene program, 198 grams of 1,2-diethoxypropane were added and then the butadiene addition rate was increased to 1.5 kg / min. A total of 36.05 kg of butadiene was added, the temperature was maintained between about 50° C. and 55° C., and the polymerization was allowed to continue until completion. A sample collected a...

example 2

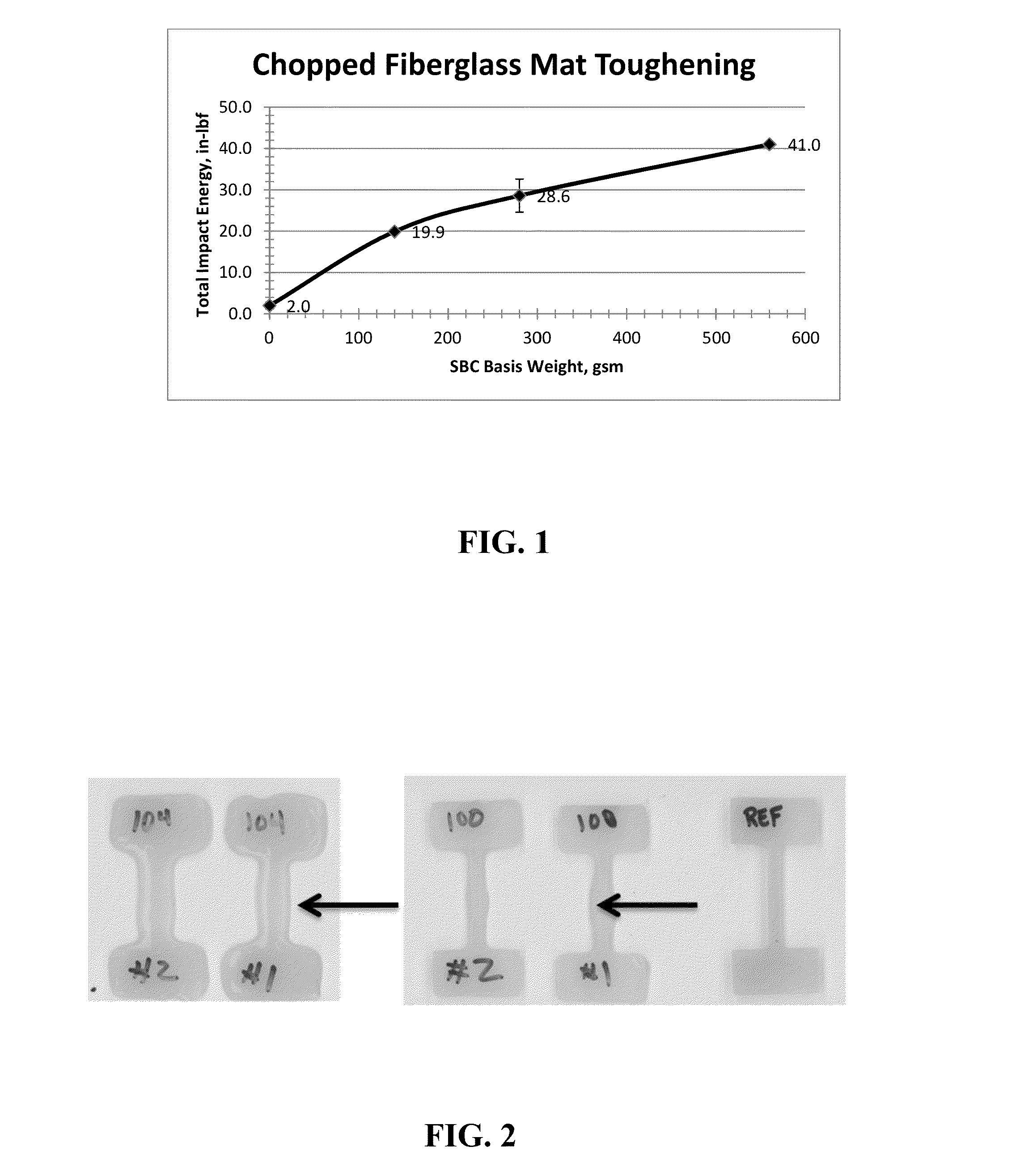

Fiberglass Mats and Scrim

[0055]The technology of the present invention is expected to provide impact resistance and enhanced toughness to composites containing fiberglass mats and scrims with significantly improved manufacturing and health, safety, and environmental aspects. The hSBS or hSBSS of the present invention having a melt flow rate >100 g / 10 min has sufficiently high molecular weight that it is not volatile and exhibits excellent elasticity and toughness while its high flow characteristics enable application as a melt blown fiber, fabric, or low basis weight film. At least 3 different processes can be envisioned to combine a tough, elastic high flow hSBS or hSBSS with a fiberglass mat or scrim.[0056]1. The melt blown fibers could be co-blown when the fiberglass is produced such that the tough, elastic fibers penetrate the thickness of the fiberglass mat.[0057]2. The film can be melt coated on top of a pre-existing fiberglass mat or scrim.[0058]3. The melt blown fabric or fi...

example 3

Low Viscosity Coatings

[0068]Low viscosity polymers (hSBS and hSBSS, as described above) are of interest in applications where VOC (volatile organic carbon) restrictions must be met. hSBS has a high melt flow rate (low viscosity) and was compared to other low viscosity polymers. It has been determined that only 4 VOC exempt solvents can be considered with hSBS, namely methyl acetate, p-chlorobenzotriflouride, t-butyl acetate, and acetone. In areas where non-VOC restrictions are acceptable, any non-exempt solvent (organic solvents that are not exempt) compatible with the low viscosity polymer may be employed. Exemplary non-exempt solvents are Aromatic 100 (a light aromatic naphtha), Aromatic 200 (a heavy aromatic naphtha), xylene, toluene, and the like. Coatings comprising a blend of solvent (exempt, non-exempt, or a mixture thereof) and at least 40 wt. % of the styrenic block copolymer of the present invention of hSBS or hSBSS have a VOC content of <450 grams / liter, preferably <350 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com