Applicators for liquid hot melt adhesive and methods of applying liquid hot melt adhesive

a liquid hot melt adhesive and application method technology, applied in the field of applications, can solve the problems of not being able to be simply stored for use, short operating life of activated liquid hot melt adhesives, etc., and achieve the effect of first viscosity that is relatively low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

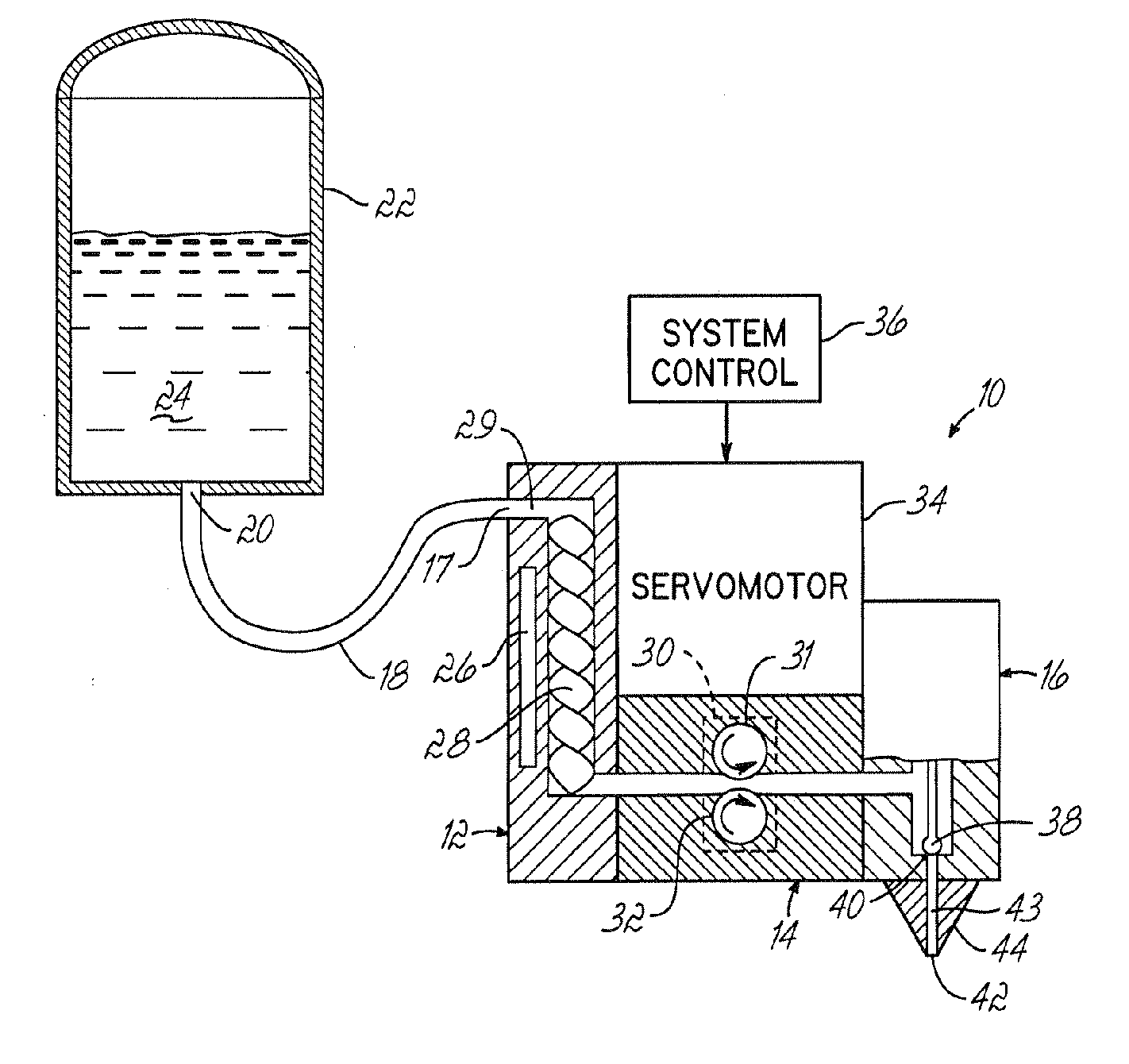

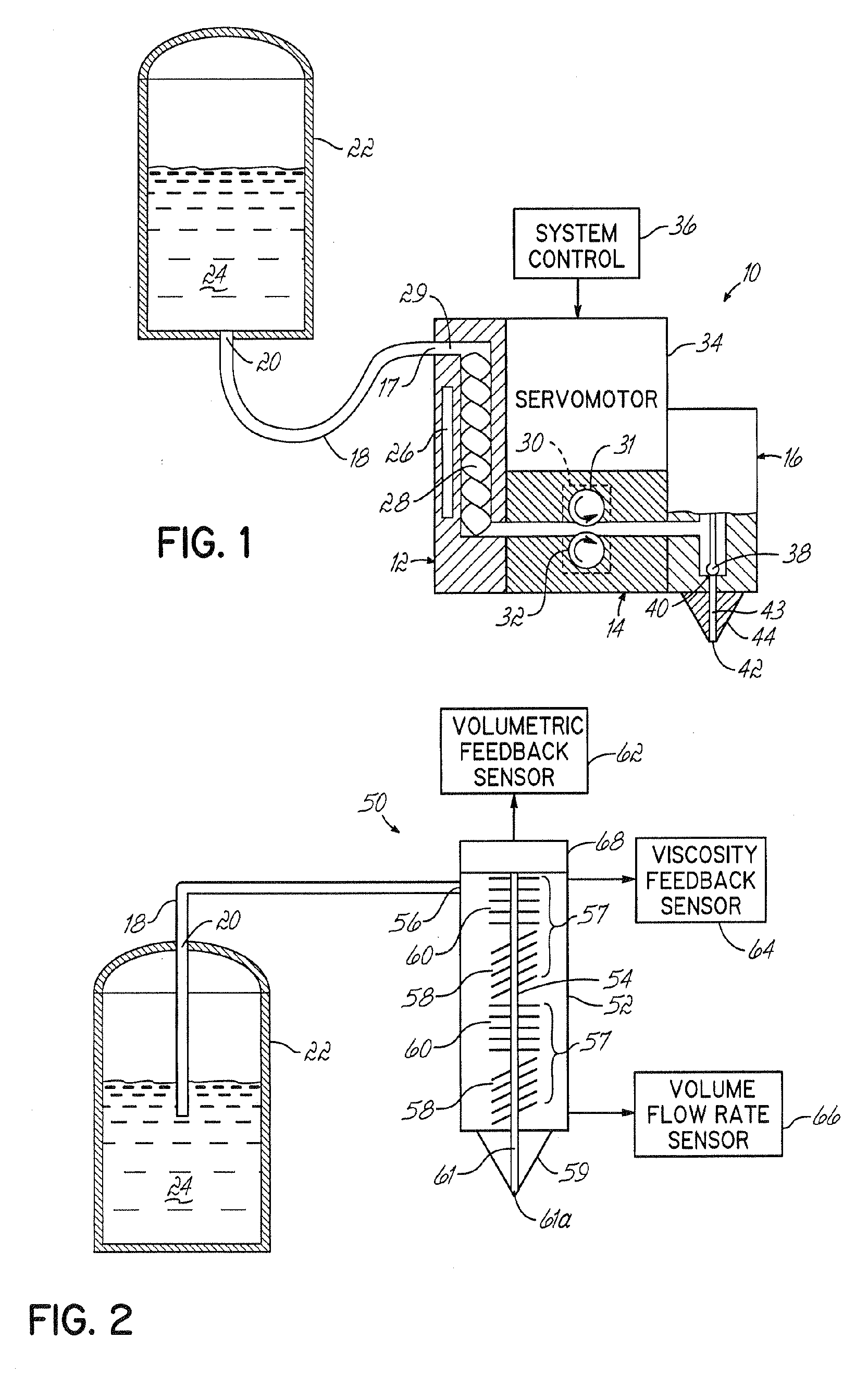

[0019] With reference to FIG. 1, an applicator 10 for intermittently dispensing viscous liquid hot melt adhesives includes a mixer / heat exchanger 12, a pumping module 14 and, optionally, at least one module or gun 16. The applicator 10 is mounted in a dispensing machine or system (not shown) in a known manner for dispensing liquid hot melt adhesive in discrete volumes, such as beads or dots, to provide an interrupted, non-continuous pattern on a moving substrate or as continuous beads or stripes. Multiple applicators 10 may be ganged together within the dispensing machine or system.

[0020] As used herein, liquid hot melt adhesive refers to any viscous liquid pumped from a bulk container in a first state and activated after pumping at, near, or proximate to an applicator by manipulating or modifying at least one activation-sensitive property of the liquid hot melt adhesive. The activation establishes a second state appropriate for adhesive bonding. For example, the changed property m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com